AshPro High-Temp Belt

products description

Jiangsu Huada’s dry ash conveyor belts are engineered to withstand extreme abrasion, high temperatures (up to 800°C), and corrosive ash in coal-fired power plants, biomass facilities, and waste incineration systems. With 30+ years of industrial expertise, our belts deliver:

50% longer lifespan vs. standard carbon steel belts

Zero material spillage with reinforced edge designs

30% lower maintenance costs (proven in 100+ MW plants)

Certifications:

√ ISO 9001:2015 | √ CE Machinery Directive | √ ASME B29.1

Why Choose Huada Dry Ash Belts?

√ Superior Heat Resistance

Material: 314/310S Stainless Steel

Continuous operation: 600-800°C

Thermal shock cycles: 2,000+ (ASTM E2899)

√ Abrasion & Corrosion Defense

Hardened surface treatment (HRC 55-60)

Resists acidic fly ash (pH 2-5)

Passes 5,000-hour salt spray test (ASTM B117)

√ Engineered Reliability

Interlocked spiral rods prevent edge fraying

Custom widths: 500-5,000mm

Load capacity: Up to 250 kg/m²

Application Scenarios

| Industry | Application | Huada Solution |

| Coal Power | Bottom ash handling | 314 SS + tungsten reinforcement |

| Biomass Plants | Fly ash conveying | Acid-resistant 316L coating |

| Waste Incineration | APC residue transport | Self-cleaning scraper design |

| Metallurgy | Slag granulation systems | Water-cooled edge protection |

Technical Parameters

| Parameter | Huada Dry Ash Belt | Industry Average |

| Max Temperature | 800°C | 600°C |

| Abrasion Loss (ASTM G65) | ≤0.8 cm³ | ≥2.5 cm³ |

| Tensile Strength | 850 N/mm² | 500 N/mm² |

| Ash Adhesion Reduction | 70% (vs. smooth surfaces) | 30% |

Case Study

500MW Coal-Fired Plant, India

After installing Huada’s dry ash belts, we achieved:

Zero unplanned downtime in 18 months

40% reduction in belt replacement frequency

ISO 14001 compliance for ash leakage control

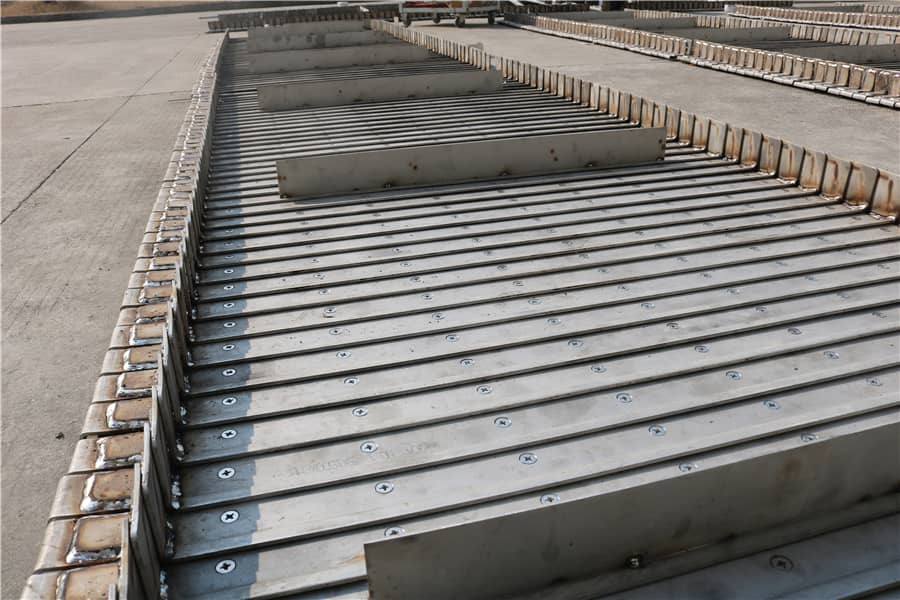

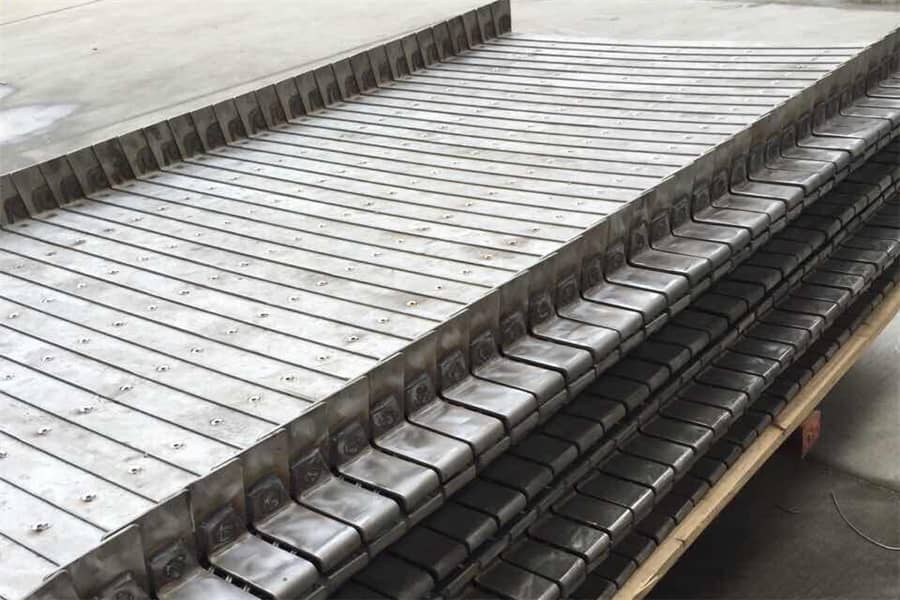

detail pictures