In the ever-evolving landscape of industrial manufacturing, the choice of equipment plays a critical role in operational efficiency and product quality. A prominent figure in the field of industrial conveyor systems, Dr. Alice Thompson, a seasoned expert in material handling solutions, emphasizes the significance of selecting the right transport medium for specific applications. She states, "A mesh belt is not just a conveyor; it is a solution that enhances both productivity and versatility in various industries."

Mesh belts have become increasingly popular due to their unique design and functionality, catering to diverse industrial needs ranging from food processing to automotive assembly. Their open structure allows for optimal airflow and drainage, making them ideal for applications requiring precise temperature control or moisture removal. Additionally, the durability and adaptability of mesh belts ensure they can withstand demanding production environments while providing reliable performance.

As industries continue to prioritize efficiency and sustainability, understanding the advantages and applications of mesh belts is crucial. This article will explore the numerous benefits of mesh belts, elaborating on how they can help businesses optimize their processes and address specific operational challenges effectively.

Mesh belts have gained significant popularity in various industrial applications due to their numerous benefits. One of the primary advantages of utilizing mesh belts is their superior ventilation and drainage capabilities. The open structure of the mesh allows air and fluids to circulate freely, which is especially important in processes involving cooling, drying, or washing. This feature not only enhances the efficiency of these processes but also contributes to improved product quality by reducing the risk of moisture retention.

In addition to ventilation, mesh belts are highly durable and resistant to wear and tear. Constructed from robust materials, they can withstand extreme temperatures and abrasive materials, making them ideal for heavy-duty applications in industries such as food processing, manufacturing, and packaging. Their flexibility and lightweight nature also simplify installation and maintenance, allowing for quick adjustments and replacements. Moreover, the ability to customize mesh belts for specific applications enhances their versatility, setting them apart as an essential component in modern industrial setups.

When considering mesh belts for industrial applications, it's essential to understand the types available and their specific uses. One popular type is the woven mesh belt, which offers excellent air circulation and cooling properties. This makes it ideal for food processing applications, where products like baked goods and fried items require efficient cooling before packaging. Woven belts also provide superior strength and durability, suitable for heavy-duty tasks in manufacturing lines.

Another type is the plastic mesh belt, which is lightweight and resistant to chemicals, making it perfect for the textile and pharmaceutical industries. These belts can be customized with various hole sizes to suit different product specifications, ensuring optimal performance in conveying materials. Additionally, modular mesh belts are gaining traction due to their easy maintenance and repair options, allowing for quick changes in production processes.

**Tips:** When selecting a mesh belt, consider the specific requirements of your application, such as temperature resistance and material compatibility. Regular maintenance, including cleaning and inspections, can prolong the lifespan of your mesh belt and improve overall efficiency. It's also crucial to ensure that the belt you choose adheres to industry standards for safety and performance.

When selecting a mesh belt for industrial applications, several factors must be considered to ensure optimal performance and durability. First, it's crucial to evaluate the material of the mesh belt, as different materials offer varying levels of resistance to heat, chemicals, and abrasion. For example, stainless steel belts are favored for their strength and resistance to corrosion, making them ideal for food processing and chemical industries.

Another important factor is the belt's design and configuration. The size of the openings within the mesh can influence airflow, product support, and ease of cleaning. A belt with larger openings may allow for better drainage and ventilation, which can be beneficial in drying or cooling applications. Additionally, it's essential to consider the belt’s load capacity and speed, as these will directly impact the overall efficiency of your production process.

**Tips:** When choosing a mesh belt, assess your specific operational requirements and environment. Conduct maintenance checks regularly to ensure the mesh belt remains in optimal condition, and consult with experts if you are uncertain about the best options for your needs. Always keep future scalability in mind; selecting a versatile mesh belt can save costs and time should your operations expand.

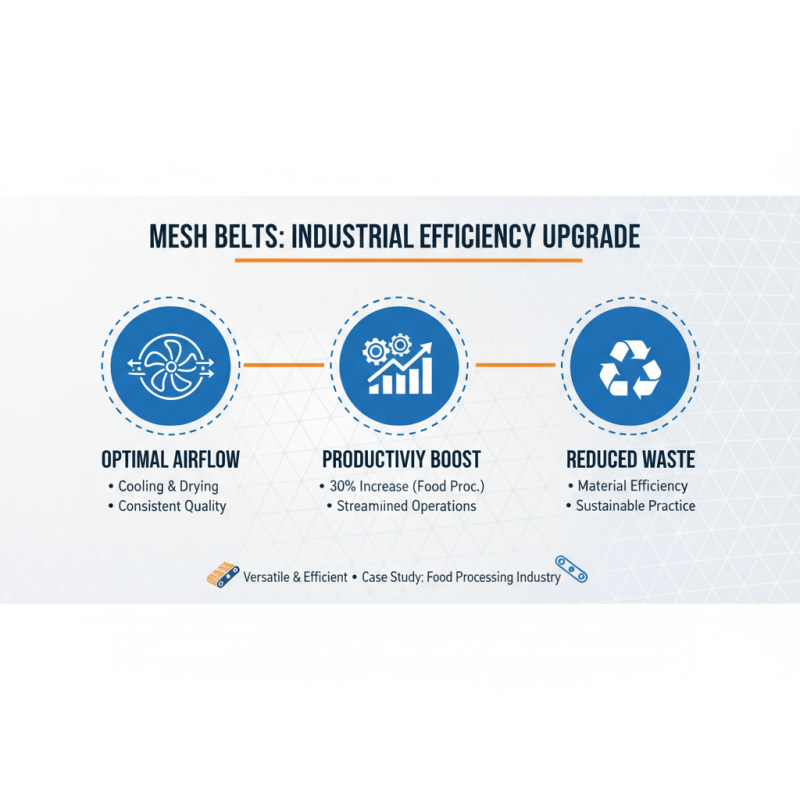

The chart above illustrates the key benefits of mesh belts utilized in industrial applications, highlighting factors such as durability, versatility, heat resistance, cost efficiency, and ease of maintenance. These attributes make mesh belts an excellent choice for various industries.

When it comes to maintaining the longevity of mesh belts in industrial applications, regular upkeep is essential. These belts, often used for their durability and versatility, can perform optimally when given the right care. One vital tip is to keep the belts clean. Regular cleaning prevents the build-up of debris and contaminants, which can lead to wear and potential malfunctions. Use a combination of pressure washing or air blowing to remove any residue, especially after intensive processing cycles.

Another important aspect of maintenance is to check for proper tension regularly. A well-tensioned mesh belt ensures smooth operation and reduces strain on the machinery. If the belt is too loose, it may slip; if too tight, it could lead to premature wear. Establish a routine inspection schedule to monitor tension, taking corrective measures as necessary. Additionally, lubricating moving parts connected to the mesh belt can further enhance performance and lifespan, minimizing friction and optimizing efficiency.

Lastly, it's crucial to ensure that the belt operates within the specified temperature and load limits. Exceeding these parameters can lead to accelerated degradation. Understanding the specific demands of your application will help in maintaining the mesh belt’s integrity, allowing it to serve your industrial needs effectively over time. By following these maintenance tips, you can ensure that your mesh belts continue to deliver reliable service.

In recent years, the implementation of mesh belts in various industrial sectors has garnered significant attention due to their versatility and efficiency. A notable case study from the food processing industry illustrates the advantages of using mesh belts for product cooling and drying applications. By integrating a mesh belt conveyor system, a leading manufacturer reported a 30% increase in productivity while maintaining consistent quality in their output. This improvement not only streamlined operations but also reduced waste, showcasing the belt's ability to facilitate optimal airflow around products, essential for effective cooling.

Another compelling example comes from the automotive industry, where a prominent assembly plant adopted mesh belts for its component handling. By utilizing these belts, they were able to transport parts through various stages of assembly without compromising quality. An industry report from the Association for Manufacturing Technology indicates that facilities employing mesh belt systems experienced an approximate 25% reduction in downtime, primarily due to fewer maintenance issues related to traditional conveyors. These cases exemplify the mesh belt's potential to enhance operational efficiency, reduce costs, and improve production timelines, ultimately supporting manufacturers' goals in a competitive marketplace.