Choosing the right Steel Wire Mesh for your project is crucial to ensuring both structural integrity and long-lasting performance. According to a report by the International Steel Mesh Association, the global market for Steel Wire Mesh is projected to reach $6.3 billion by 2025, growing significantly driven by the construction and industrial sectors. With rising demand, it becomes essential for professionals to understand the various types of Steel Wire Mesh available and their specific applications.

Industry expert Dr. Michael Harmon, a leading authority on material engineering, emphasizes the importance of proper selection when he states, "The right Steel Wire Mesh can significantly enhance the durability and stability of construction projects, making it a critical component in modern engineering." As construction requirements evolve, so does the variety of Steel Wire Mesh products, each designed to meet different needs, from construction reinforcement to architectural applications. By carefully considering factors such as mesh size, wire diameter, and coating options, you can ensure your project not only meets regulatory standards but also performs optimally in its intended environment.

When selecting the right steel wire mesh for your project, it is crucial to understand the various types available on the market. Steel wire mesh can be categorized mainly into welded wire mesh, woven wire mesh, and barbed wire mesh, each serving distinct purposes. According to a recent industry report from Grand View Research, the global wire mesh market is expected to grow at a CAGR of 5.5% from 2022 to 2030, reflecting an increased demand in construction, agriculture, and industrial applications.

Welded wire mesh is widely favored for its durability and strength, making it an excellent choice for concrete reinforcement or as a barrier in construction sites. It typically consists of lines of steel wire welded at intersections, providing a secure structure that minimizes the risk of rust and corrosion when properly coated. Conversely, woven wire mesh offers versatility and flexibility, ideal for uses such as fencing and filtration. Its manufacturing process involves weaving wires together, creating a porous material that permits air and water flow, making it suitable for agricultural applications as well.

Barbed wire mesh, often used for security fences and agricultural boundaries, presents another option. This type features sharp edges or points that deter intruders and livestock from crossing designated areas. Data from Market Research Future indicates that barbed wire production is projected to witness robust growth due to rising security concerns in various sectors. Understanding these types will guide your selection process, ensuring you choose a steel wire mesh that meets the specific demands of your project.

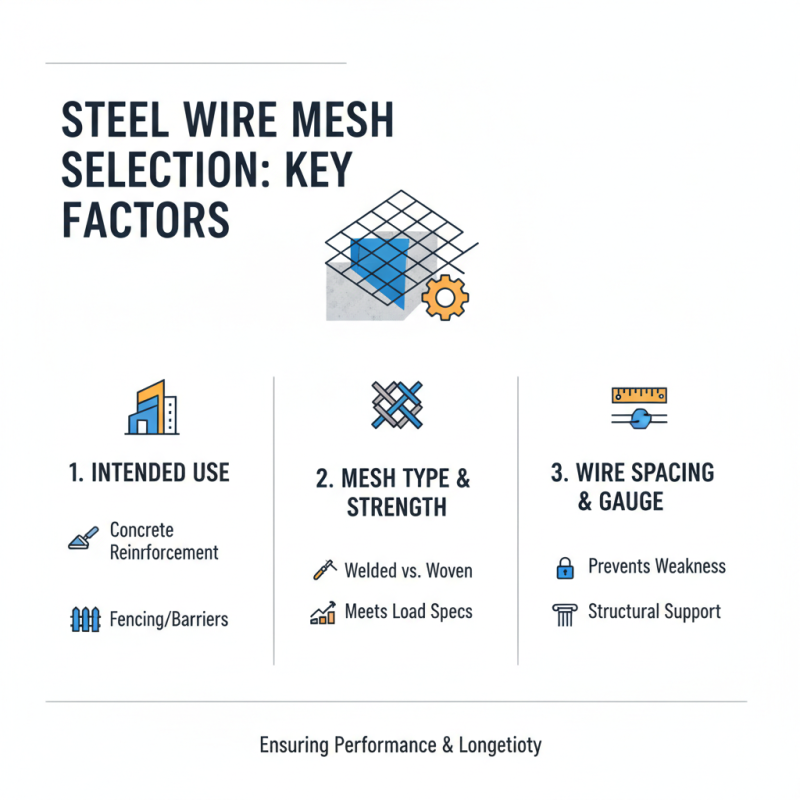

This chart illustrates the various types of steel wire mesh and their common applications, helping you make an informed decision for your project.

When selecting steel wire mesh for your project, there are several key factors to consider that can significantly impact the performance and longevity of the installation. First and foremost, the intended use of the mesh should drive your selection process. For example, if the mesh is to be used for concrete reinforcement, choosing a welded or woven type that meets specific strength requirements is critical. Additionally, ensure that the mesh has adequate spacing between wires to prevent any structural weakness while providing the necessary load-bearing capabilities.

Another crucial aspect to consider is the material specifications, particularly the type of steel used in the wire mesh. Different steel grades offer varying levels of corrosion resistance and strength. If your project is exposed to harsh environmental conditions, opting for galvanized or stainless steel mesh could enhance durability and reduce maintenance needs. Furthermore, understanding the mesh's wire diameter and opening size is vital to ensure it accommodates your project's specific requirements, such as airflow or drainage, without compromising its strength. Careful consideration of these factors will lead to more effective and long-lasting results in your project.

When selecting steel wire mesh for your project, understanding its strength and durability characteristics is critical to ensuring optimal performance and longevity. Steel wire mesh is typically evaluated based on various parameters, including tensile strength, yield strength, and fatigue resistance. According to a report by the American Institute of Steel Construction (AISC), high-strength steel wire meshes can achieve tensile strengths exceeding 70,000 psi, making them suitable for heavy-duty applications in construction and infrastructure development.

Durability is another vital factor to consider when choosing steel wire mesh. Corrosion resistance is paramount, especially in environments exposed to moisture or chemicals. Research published in the Journal of Materials Science indicates that galvanized steel wire mesh can significantly improve longevity, offering protection against rust and extending the material's life span by up to 50% compared to untreated steel. Additionally, the choice of coating, such as epoxy or PVC, can enhance the mesh's resistance to harsh environmental conditions, thus ensuring durability over time.

In summary, the key to selecting the right steel wire mesh lies in a thorough analysis of its strength and durability characteristics. By understanding the specifications and environmental impacts, project planners can make informed decisions that will enhance the overall quality and lifespan of their projects. Robust data from industry reports emphasizes the importance of careful material selection to mitigate risks associated with structural failures or premature wear.

| Mesh Type | Wire Diameter (mm) | Aperture Size (mm) | Strength (N/mm²) | Corrosion Resistance | Durability Rating |

|---|---|---|---|---|---|

| welded mesh | 4.0 | 50x50 | 450 | High | 8/10 |

| expanded metal | 3.0 | 20x20 | 350 | Moderate | 7/10 |

| chain link | 2.5 | 40x40 | 300 | Low | 5/10 |

| reinforcement mesh | 5.0 | 200x200 | 500 | High | 9/10 |

Steel wire mesh is a versatile material with numerous applications across various industries due to its strength, durability, and flexibility. In the construction sector, for instance, steel wire mesh is extensively used for concrete reinforcement, enhancing structural integrity. The Global Concrete Reinforcement Market Report indicates that the demand for concrete products, particularly those reinforced with steel mesh, is projected to grow at a CAGR of 4.5% over the next five years, driven by increased infrastructure investments globally. This trend showcases the critical role of steel wire mesh in ensuring building safety and longevity.

In addition to construction, steel wire mesh serves important functions in the agricultural sector. Used for fencing, livestock containment, and soil erosion control, it has proven essential in maintaining productivity and sustainability in farming practices. A report by the Agricultural Wire Fencing Association highlights that the demand for agricultural wire fencing is anticipated to rise, with the market expected to expand by approximately 6% annually as farmers seek to improve efficiency and protect their crops and livestock. Furthermore, in the industrial sector, steel wire mesh is used in filtration and screening processes, illustrating its adaptability across a spectrum of challenges in manufacturing and processing. Such diverse applications emphasize the importance of selecting the right type of steel wire mesh tailored to specific project needs.

When embarking on a project that requires steel wire mesh, one of the most critical aspects to consider is the budget. According to recent industry reports, the average cost of steel wire mesh can range from $0.15 to $1.75 per square foot, depending on the type, gauge, and dimensions required. It’s essential to determine not only the initial cost of materials but also the potential long-term savings associated with durability and maintenance. Investing in higher-quality mesh might appear costlier upfront, but it often saves money in the long run by reducing the need for replacements.

Tip: Always factor in the specific requirements of your project when budgeting for steel wire mesh. This includes assessing the load-bearing capacity needed and any environmental factors that might affect the choice of materials. Consulting with industry professionals can provide insights into cost-effective options that meet your project's demands without compromising quality.

Plan for additional costs such as shipping, handling, and installation, which can significantly influence the overall budget. It's advisable to acquire multiple quotes from suppliers to compare prices and ensure that you are getting the best deal without sacrificing quality. Remember, the cheapest option isn't always the best; focusing on value will lead to a more successful project outcome.

Tip: Keep an eye on fluctuating steel prices, as they can impact your budget unexpectedly. Regularly reviewing market trends can help you make informed purchasing decisions that align with your financial plan.