In the ever-evolving industrial landscape, the efficiency of machinery and equipment is critical to optimizing operational performance. A key component influencing this efficiency is the selection and application of **Industrial Belting** solutions. According to a report by Grand View Research, the global industrial belt market size was valued at approximately $5.52 billion in 2021, with expectations to exhibit a compound annual growth rate (CAGR) of 4.2% from 2022 to 2030. This robust growth underscores the essential role that advanced belting solutions play in enhancing productivity and durability across various sectors, including manufacturing, logistics, and automotive.

Industrial belting materials have evolved significantly, driven by the need for improved performance characteristics and extended service life. The importance of choosing the right belting solution is further highlighted by a study conducted by MarketsandMarkets, which estimates that the demand for high-performance conveyor belts alone is projected to reach $6.87 billion by 2026. Such advancements not only reduce maintenance costs but also improve energy efficiency, ultimately contributing to lower operational expenditures for businesses.

As industries continue to integrate automation and embrace technology, understanding the intricacies of industrial belting applications becomes paramount. Companies that invest in high-quality, durable belting solutions are better positioned to meet stringent operational demands while achieving enhanced performance and reliability in their processes.

In today's industrial landscape, the choice of belting solutions plays a significant role in optimizing operational performance and ensuring durability. Industrial belts are engineered to withstand demanding conditions, featuring materials and designs that mitigate wear and tear over time. With enhanced performance in mind, various types of belts—such as flat, modular, and timing belts—are specifically tailored to meet the unique requirements of different applications. Their ability to maintain consistent traction and reduce slippage not only improves efficiency but also extends the life cycle of machinery.

Moreover, the durability of industrial belting solutions is crucial in minimizing downtime and reducing maintenance costs. Advanced manufacturing techniques and material innovations have led to belts that resist abrasion, heat, and chemical exposure, making them suitable for a wide range of industries, from manufacturing to food processing. Investing in high-quality belting solutions ultimately translates to improved productivity, as these belts are designed to handle heavy loads and operate reliably under stress. This careful selection of belting not only supports immediate operational goals but also fosters long-term sustainability in industrial practices.

Industrial belting plays a crucial role in manufacturing processes, acting as a fundamental component that impacts efficiency and productivity. These belts are designed to transport materials, support machinery, and facilitate various operational tasks within an industrial setting. Understanding the importance of industrial belting begins with recognizing its functions: they provide reliable movement of goods, minimize downtime, and ensure that production flows seamlessly across different stages of manufacturing.

Durability and performance are key factors in the selection of industrial belting solutions. High-quality belts can withstand harsh environments, abrasion, and chemical exposure, thereby prolonging their lifespan and reducing replacement frequency. The right belt not only enhances operational efficiency but also contributes to a safer workplace by minimizing the risk of mechanical failures. As manufacturing processes evolve, so too do the innovations in belting technology, offering advanced solutions that cater to specific industry needs and meet stringent performance standards.

When selecting industrial belting solutions, understanding the various types of materials available is crucial for optimizing performance and longevity. Common materials for industrial belts include rubber, PVC, polyurethane, and fabric composites. Rubber belts are known for their flexibility and resistance to abrasion, making them ideal for heavy-duty applications such as material handling and conveyor systems. Their ability to withstand harsh conditions, including extreme temperatures and exposure to chemicals, ensures minimal downtime and maintenance.

PVC belts, on the other hand, are favored for their lightweight properties and affordability. They offer excellent resistance to water, oils, and solvents, making them suitable for food processing and packaging industries. Polyurethane belts are recognized for their durability and superior resistance to cuts and tears, which are pivotal in high-stress environments. Additionally, fabric composite belts provide versatility and strength, finding applications in automotive and engineering sectors due to their ability to handle a range of loads while maintaining traction.

Choosing the right material depends on the specific demands of the application, including load capacity, chemical exposure, and temperature conditions. By assessing these factors, industries can enhance their operational efficiency and achieve greater durability in their belting solutions.

The performance and longevity of conveyor belts are influenced by several critical factors that industry professionals must consider. One of the primary factors is the material composition of the belt itself. Different applications require various materials, which can affect strength, abrasion resistance, and temperature tolerance. For instance, belts made from synthetic materials may provide enhanced durability and flexibility, while rubber belts could offer better grip and resistance to wear in specific environments. Recognizing the optimal material for the intended application is essential for maximizing efficiency and minimizing breakdowns.

Another crucial aspect is the operating environment where the conveyor belts are used. Factors such as temperature fluctuations, humidity levels, and exposure to chemicals can significantly impact the lifespan of the belts. For example, high temperatures may lead to thermal degradation, while exposure to corrosive substances can weaken the belt structure over time. Therefore, understanding the specific conditions in which the conveyor system operates allows for better material selection and maintenance strategies to ensure the belts perform reliably.

Finally, regular maintenance practices play a vital role in prolonging the life of conveyor belts. Routine inspections for wear and tear, proper alignment, and tension adjustments can prevent minor issues from escalating into major failures. Additionally, the choice of lubrication and cleaning regimes can facilitate smoother operation and reduce friction, ultimately enhancing performance. By focusing on these factors, industries can optimize their conveyor systems for both durability and efficiency.

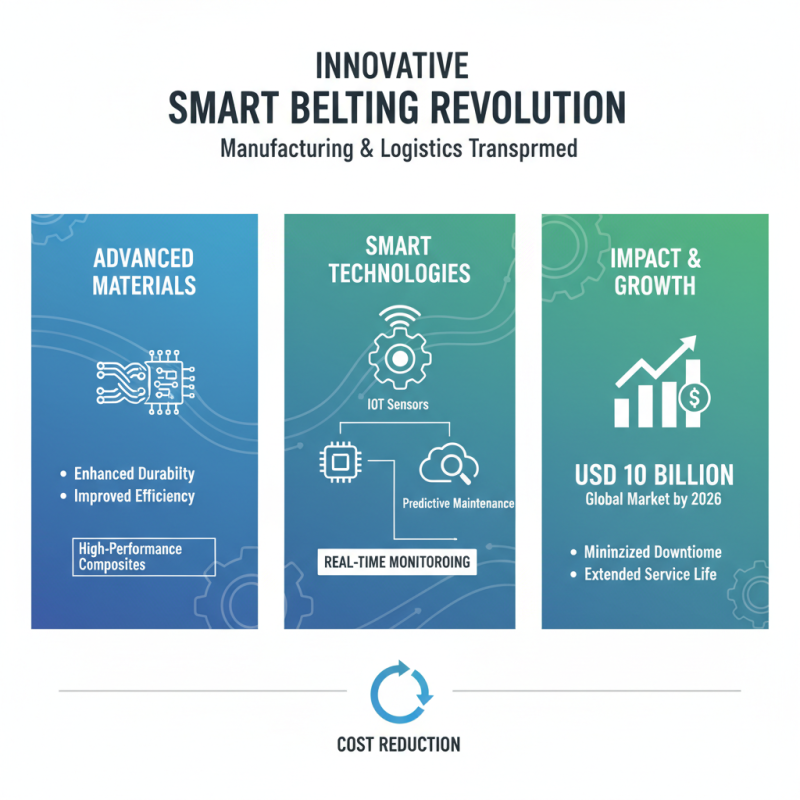

Innovative technologies in industrial belting solutions are revolutionizing the manufacturing and logistics sectors, enhancing both performance and durability. With the global industrial belting market expected to reach USD 10 billion by 2026, companies are increasingly adopting advanced materials and designs that improve efficiency and reduce costs. The integration of smart technologies, such as IoT sensors and predictive maintenance software, allows for real-time monitoring of belt conditions, resulting in minimized downtime and extended service life.

In addition to technological advancements, research indicates that the use of specialized materials, such as polyurethane and reinforced rubber composites, can significantly enhance the load-bearing capacities of belts. According to a recent report by Smithers Pira, belts made with these innovative materials can increase performance efficiency by up to 20%, while also providing resistance to wear and environmental factors—crucial in sectors like food processing and mining.

**Tips:** Regularly monitor your belting systems using data analytics to identify potential issues before they lead to failures. Implementing scheduled maintenance checks can help prolong the lifespan of your belts. Additionally, consider training staff on the latest technologies and materials to ensure optimal usage and performance. Keeping abreast of advancements in belting technology through industry publications can also equip your team with the knowledge needed to make informed decisions.

Industrial belting plays a crucial role in enhancing the performance and durability of manufacturing processes. Understanding the various types of industrial belt materials and their specific applications is essential for optimizing operations. Factors such as load capacity, environmental conditions, and wear resistance significantly influence the performance and longevity of conveyor belts.

Incorporating innovative technologies into industrial belting solutions can lead to improved efficiency and reduced downtime. Moreover, best practices for maintaining and replacing industrial belts are vital for ensuring seamless operations and prolonging the lifespan of the equipment. By considering these aspects, companies can achieve reliable and durable performance in their manufacturing processes.