High-Quality OEM Chocolate Conveyor Belts from Trusted Manufacturers

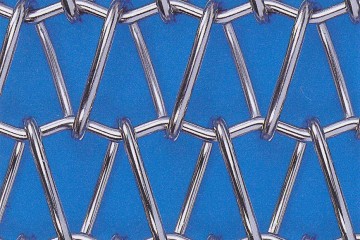

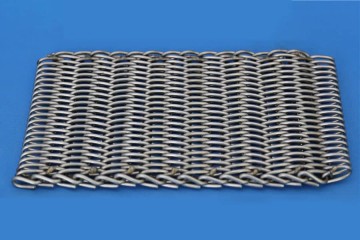

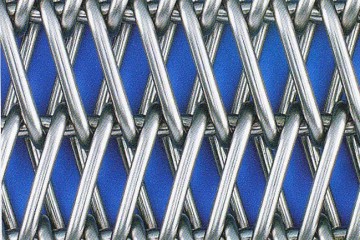

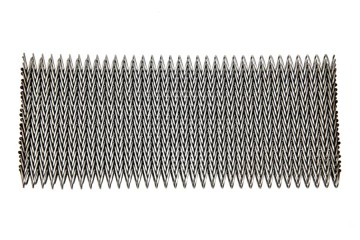

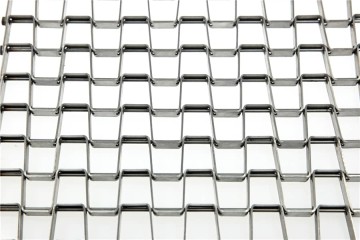

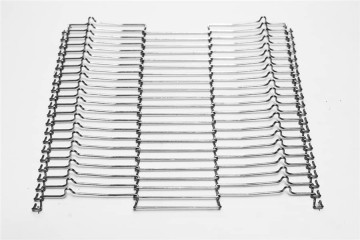

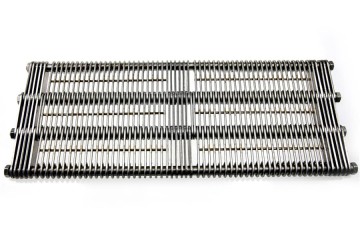

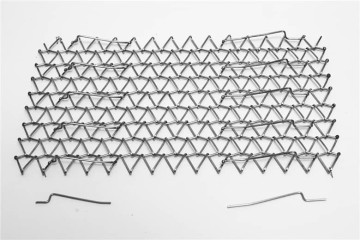

Are you seeking a dependable solution for your chocolate production line? Our Chocolate Conveyor Belt is designed for precision and efficiency, ensuring smooth and controlled handling of chocolate while minimizing breakage and waste. As an OEM factory specializing in high-quality metal mesh belts, we cater to the unique requirements of the food industry. Crafted from durable materials, our belts are built for heavy-duty use in chocolate manufacturing. Each belt is customized to fit your specific operational needs, promoting a seamless flow in your production process. Partnering with us ensures access to excellent products, expert support, and tailored options, helping you enhance your chocolate production efficiency and maintain the highest product quality. Let's optimize your chocolate processing together!7 Key Tips To Chocolate Conveyor Belt Factory Factory-Direct Excellence

In the fast-paced world of chocolate production, efficiency and precision are paramount. As a global buyer in search of top-notch manufacturing solutions, understanding the key features of a quality chocolate conveyor belt is crucial. At JIANGSU HUADA METAL MESH BELT CO., LTD., we leverage our expertise as China’s pioneering Metal Conveyor belt manufacturer to enhance your production line. Here are seven essential tips to ensure factory-direct excellence in your chocolate conveyor belt solutions. Firstly, prioritize quality certification. Our ISO 9001 and CE certified production facilities guarantee that the wire mesh belts and chain-driven systems meet international standards, ensuring durability and reliability in your processing environment. Secondly, consider customization options. Each chocolate production line has unique requirements, and our engineering team is adept at designing bespoke solutions that cater to your specific needs. Efficiency is key; optimizing the belt speed and alignment can significantly enhance chocolate handling, reducing waste and improving overall throughput. Moreover, focus on maintenance and support. A reliable manufacturer, like HUADA, offers continuous support and readily available spare parts, minimizing downtime in your operations. Additionally, look for a supplier with a proven international presence. With shipments to over 20 countries spanning five continents, we understand the diverse needs of global clients, allowing us to provide tailored solutions. By following these tips, you can ensure your chocolate conveyor belt system operates at peak performance, contributing to your factory’s success.

7 Key Tips To Chocolate Conveyor Belt Factory Factory-Direct Excellence

| Tip | Description | Expected Outcome |

|---|---|---|

| Optimize Conveyor Speed | Adjusting the speed of the conveyor belt to match production needs and prevent product damage. | Increased efficiency and reduced waste. |

| Regular Maintenance | Implementing a schedule for regular maintenance of conveyor systems. | Extended conveyor lifespan and fewer breakdowns. |

| Train Employees | Providing proper training on conveyor operations and safety protocols. | Improved safety and operational knowledge among staff. |

| Use Quality Materials | Choosing high-quality materials for conveyor systems to ensure reliability. | Enhanced performance and durability. |

| Implement Automation | Integrating automation technologies to streamline operations. | Reduced labor costs and increased throughput. |

| Monitor Load Distribution | Ensuring even load distribution on the conveyor belt to prevent jams. | Smoother operations and less downtime. |

| Conduct Regular Audits | Performing frequent audits to identify inefficiencies and areas for improvement. | Continuous improvement and optimal performance. |

How To Evaluate Chocolate Conveyor Belt Supplier Guarantees Peak Performance

T

Thomas Adams

Incredible quality! My experience with the customer service team was nothing short of perfect.

22 May 2025

L

Laura Harris

Outstanding purchase! The quality is evident, and the after-sales support was incredible.

20 May 2025

A

Andrew Hill

Fantastic product! The after-sales staff is knowledgeable and incredibly helpful.

27 June 2025

E

Emily Hall

Great craftsmanship! The customer service team was always available and extremely knowledgeable.

19 June 2025

K

Kevin Scott

Absolutely love it! The quality is amazing and the service team exhibited great professionalism.

15 June 2025

N

Natalie Martinez

High-quality product! The support team’s expertise made the entire process smooth.

22 May 2025