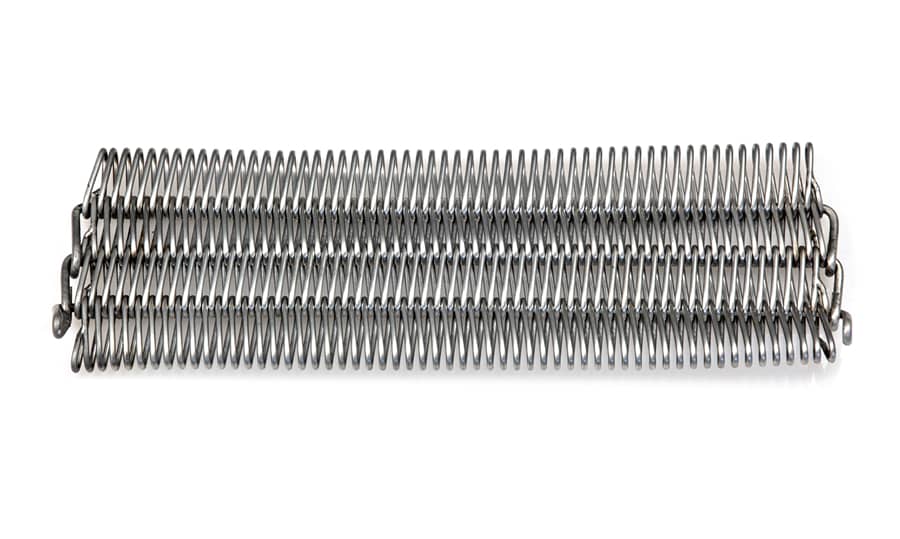

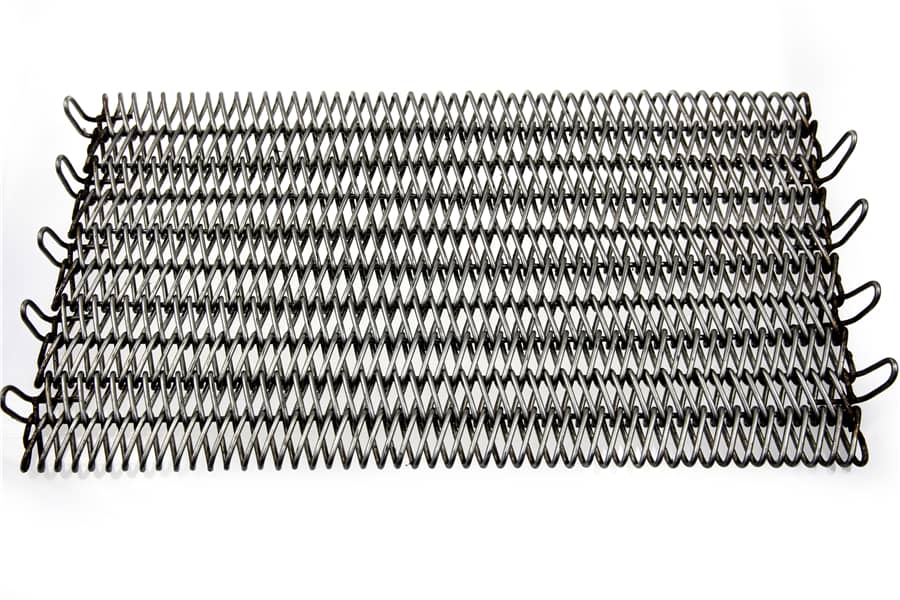

Clinch Edge Type Belt

products description

Jiangsu Huada’s clinch edge conveyor belts are engineered for the extreme demands of powder metallurgy, combining 1050°C heat resistance, 5kg/cm² load capacity, and zero surface flaking during prolonged high-temperature exposure.

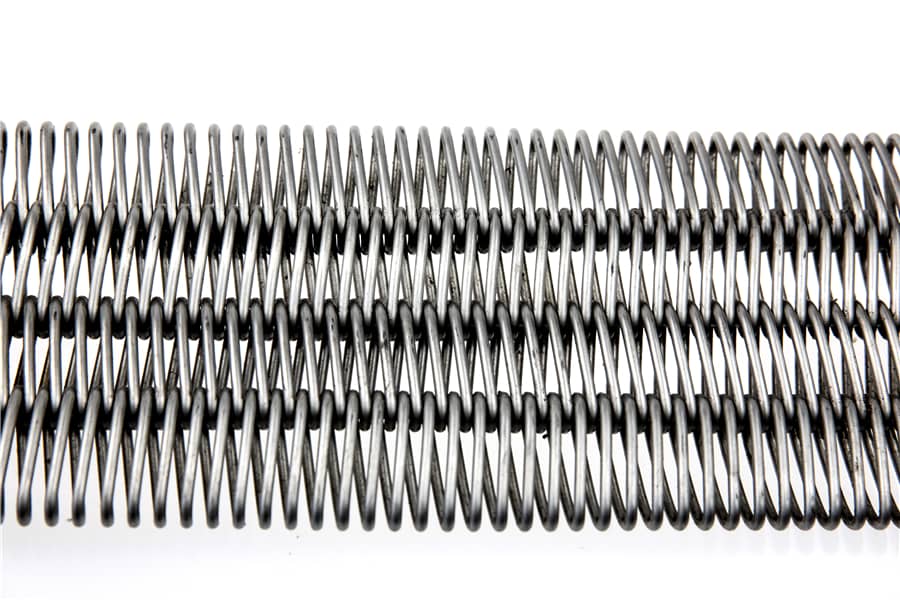

Key advantages:

Thick 3.0-5.0mm wire diameter withstands heavy PM parts

Oxidation-stable surface (mass gain <1mg/cm² @800°C/100h)

Anti-flake guarantee (ISO 14644-1 Class 5 compliant)

Certifications:

√ ISO 9001:2015 | √ ASTM A480 | √ MPIF Standard 35

Technical Advantage

√ High-Temperature Endurance

Material: 314/310S Stainless Steel

Continuous operation: 800-1050°C (H₂/N₂ atmosphere)

Thermal cycling: 2000+ cycles (ASTM E606)

√ Heavy-Load Capacity

Wire diameter: 3.0-5.0mm (customizable)

Load rating: Up to 5kg/cm² (vs. 3kg/cm² industry standard)

Tensile strength: 800-1000 N/mm²

√ Oxidation Stability

Surface oxide layer adhesion: Grade A (ASTM D3359)

Mass gain: <1mg/cm² after 100h @800°C

Zero particulate shedding (ISO 14644-1 Class 5)

Application Scenarios

| PM Process | Challenge | Huada Solution |

| High-Load Sintering | Deformation under heavy parts | 5.0mm wire + cross-rod reinforcement |

| High-Temp Debinding | Surface oxidation contamination | 310S with stable oxide layer |

| Large PM Parts Transfer | Mesh sagging | 4.5mm wire @50mm pitch design |

| Clean Sintering | Oxide flake contamination | Electropolished Ra ≤0.6μm surface |

Technical Parameters

| Parameter | Huada PM Belt | Industry Standard |

| Max Operating Temp | 1050°C | 750°C |

| Load Capacity | 5kg/cm² | 3kg/cm² |

| Oxidation Mass Gain | <1mg/cm² (100h@1000°C) | 3-5mg/cm² |

| Wire Diameter Options | 3.0-5.0mm | 2.0-4.0mm |

Case Study: Automotive PM Component Supplier

After adopting Huada’s belts:

Zero part deformation with 4.2mm wires under 4.8kg/cm² loads

No oxide contamination in 10,000 sintered gears

Reduced 30% maintenance costs over 18 months

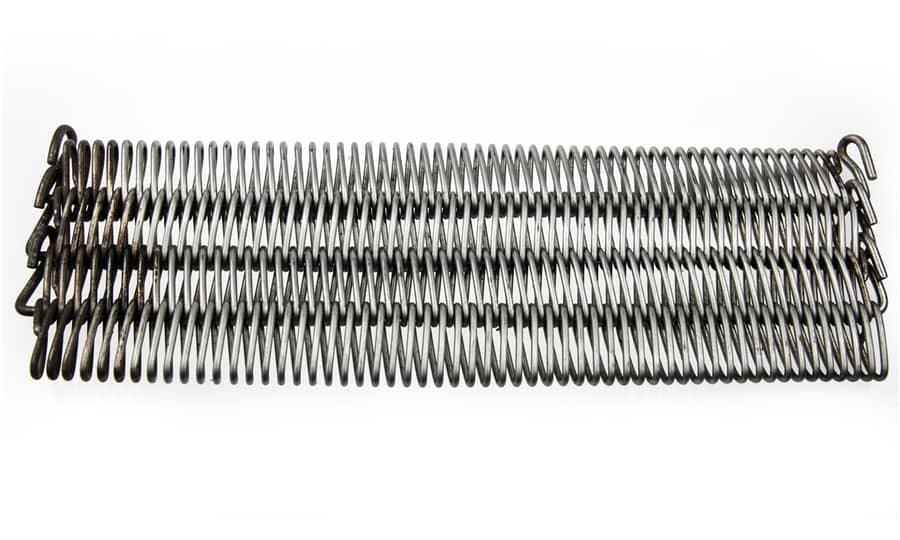

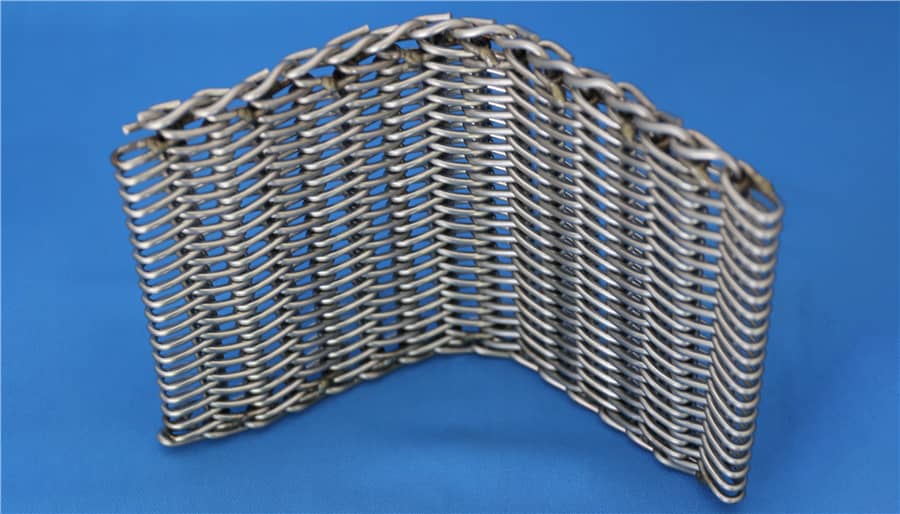

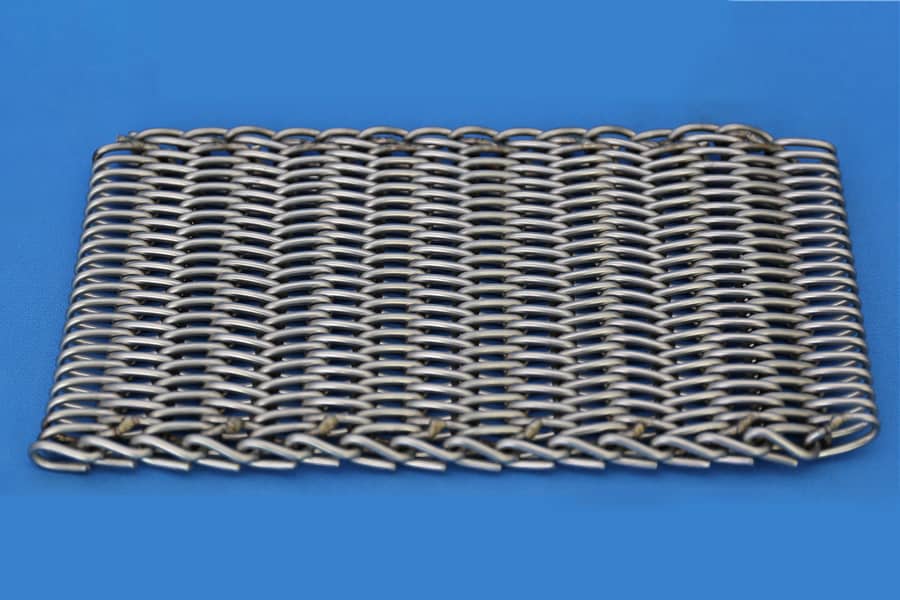

detail pictures