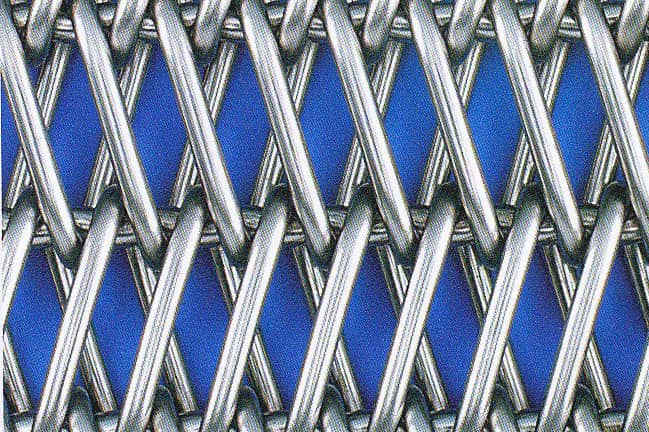

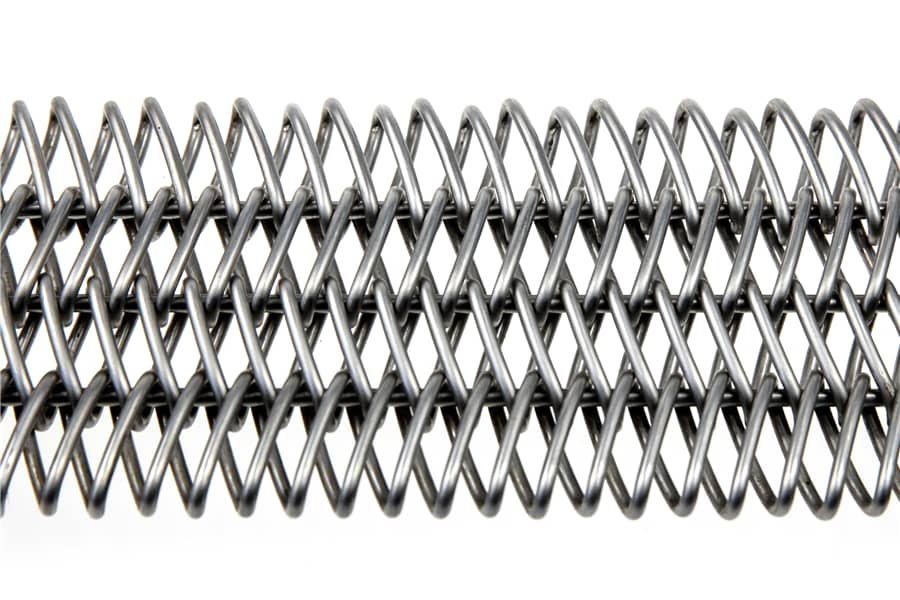

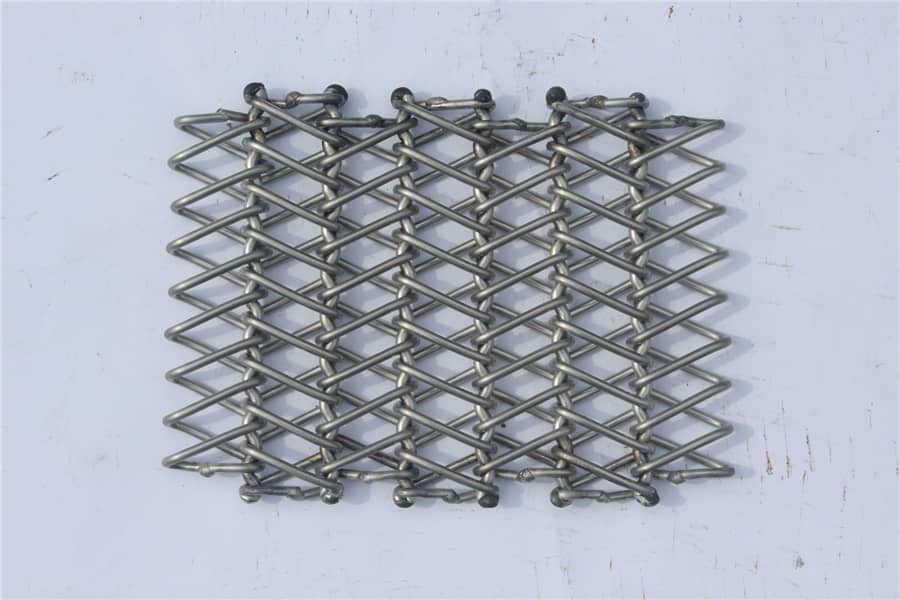

Double Balance Belt

products description

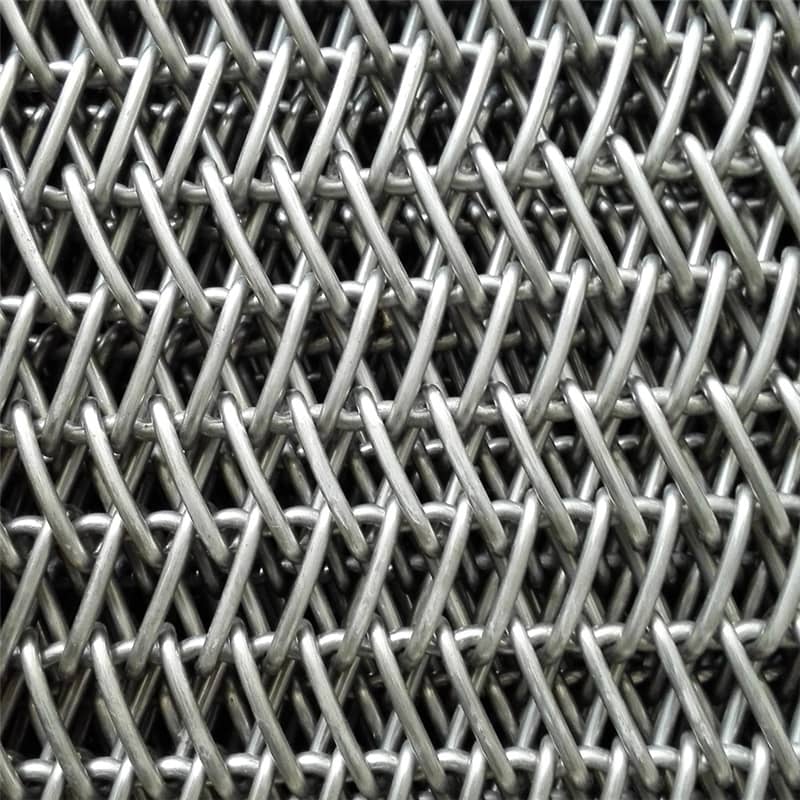

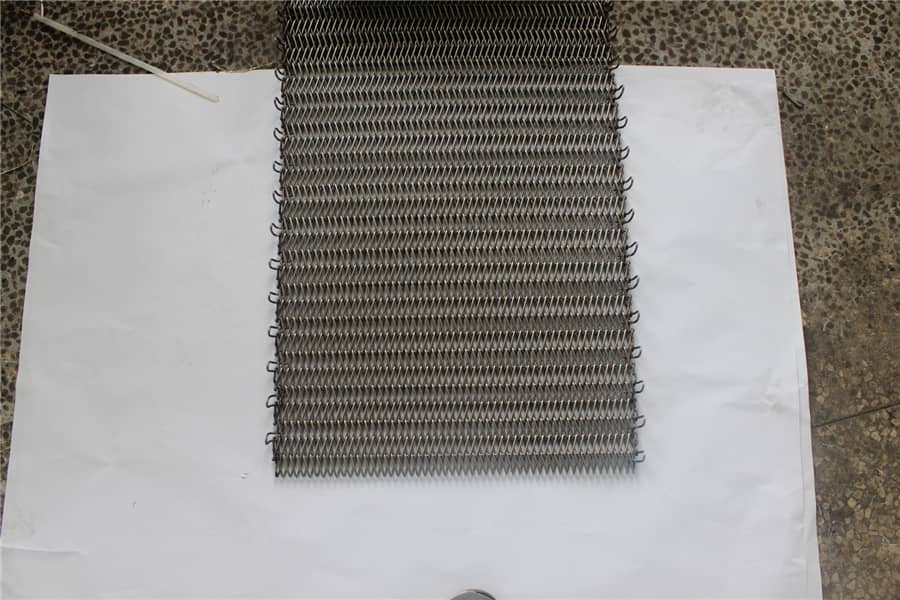

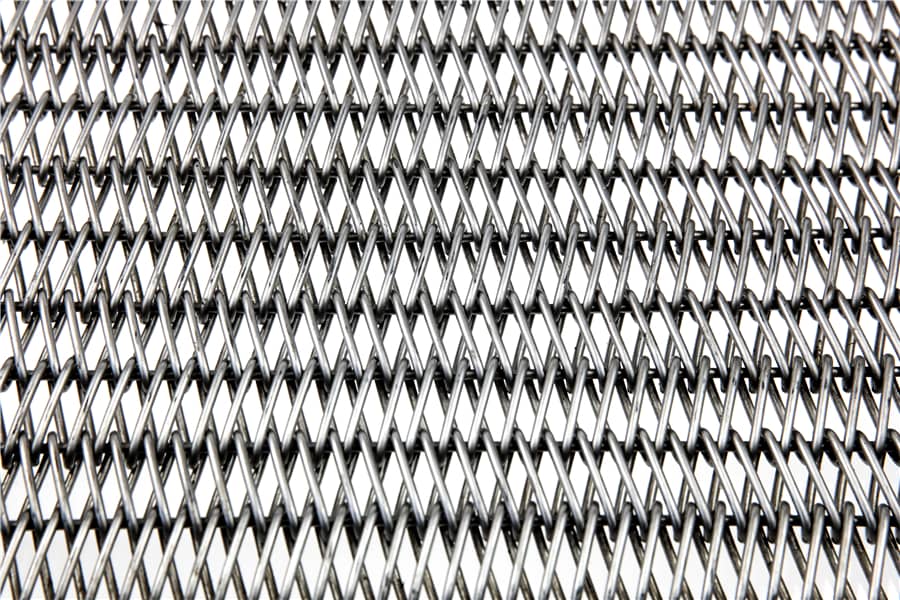

Double balance weave type is for applications with particularly high load or for the products which require a narrower aperture. Mostly use stainless steel material.

Jiangsu Huada’s double balance weave belts combine dual-layer precision weaving and cross-rod reinforcement to deliver unmatched stability in extreme industrial environments. Engineered with 314/316L stainless steel, our belts provide:

1,000 kg/m² Load Capacity (2X standard single-layer belts)

±0.1mm/m Linear Accuracy for precision automation

800°C Continuous Operation with zero warping

Certifications:

√ ISO 9001:2015 | √ CE Machinery Directive | √ FDA 21 CFR 177.2600

Technical Advantage

√ Extreme Load Performance

Dual-layer interlock design with 3.0-6.0mm wire diameter

Tensile strength: 1,000-1,800 N/mm² (customizable)

Fatigue life: 50% longer than single-layer belts

√ Thermal Resilience

Material options: 314 SS (800°C) / Inconel 601 (1,150°C)

Thermal expansion coefficient: 12.8×10⁻⁶/°C

√ Precision Engineering

Cross-rod alignment tolerance: ±0.15mm over 10m

Optional ESD-safe coating (10⁶-10⁹Ω surface resistance)

Application Scenarios

| Industry | Application | Huada Solution |

| Mining | Iron ore primary crushing | 6.0mm wires + tungsten rods |

| Automotive | Body panel stamping lines | 5.0mm dual-layer anti-vibration |

| Glass | Tempered glass annealing | Zero deflection at 650°C |

| Food Processing | High-speed baking conveyors | 316L SS with EHEDG certification |

Technical Parameters

| Parameter | Huada Double Balance Belt | Industry Standard |

| Max Load Capacity | 1,000 kg/m² | 500 kg/m² |

| Wire Diameter Options | 3.0-6.0mm | 2.0-4.0mm |

| Temperature Range | -50°C to 800°C | -20°C to 600°C |

| Abrasion Loss (ASTM G65) | 0.4 cm³ | 1.5 cm³ |

Case Study: Automotive Tier-1 Supplier

Huada’s double balance belts achieved:

Zero misalignment in 1M+ stamping cycles

30% faster line speed with 4.5mm wire design

Reduced 35% maintenance costs over 2 years

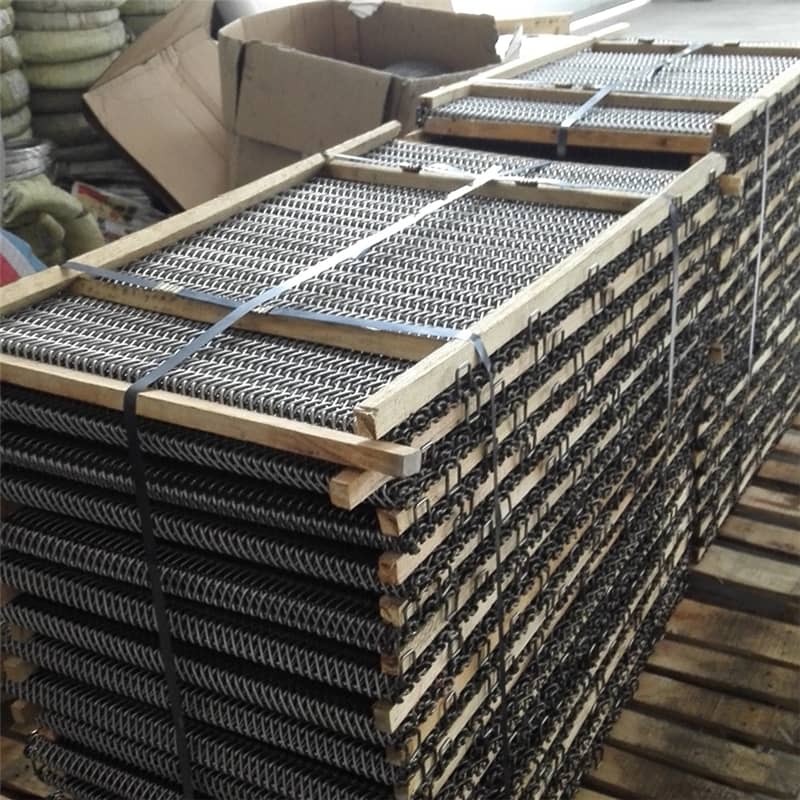

detail pictures