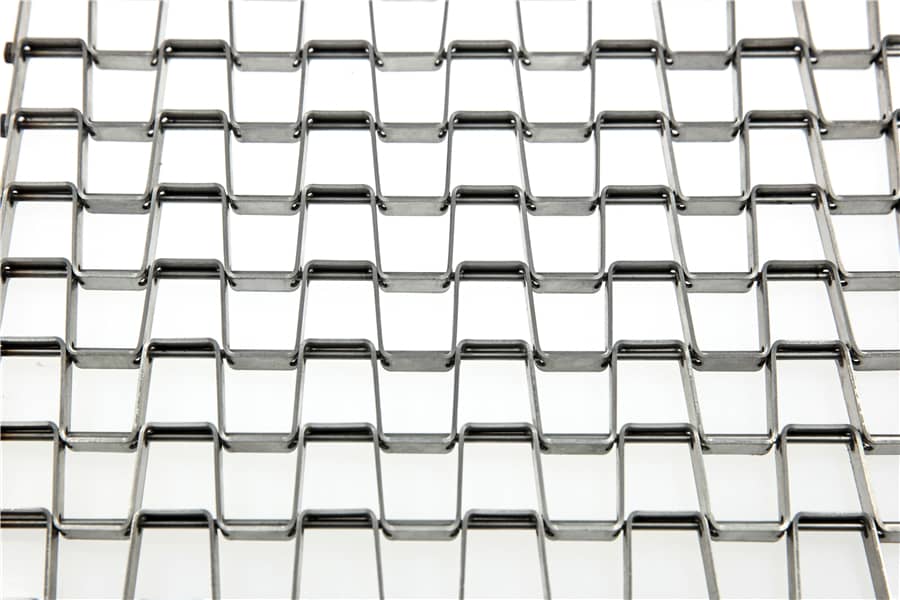

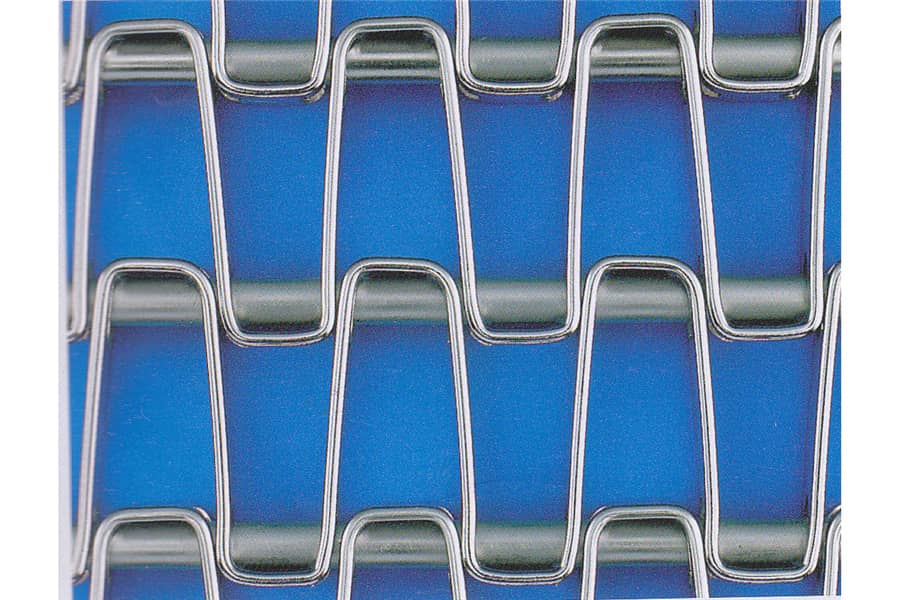

Flat Wire Belt

products description

Honeycomb flat wire belts (304/316 SS) withstand 800°C for heat treatment/drying/washing. FDA & ISO 9001 certified with ±0.3mm stability. Large open mesh enhances air circulation & cleaning efficiency.

Jiangsu Huada’s flat wire conveyor belts are engineered for precision handling in demanding industrial environments. Featuring ultra-flat welded surfaces (Ra ≤0.4μm) and 316L/314 stainless steel construction, our belts deliver:

Zero Product Snagging for fragile items like PCBs or baked goods

Continuous Operation from -40°C to 800°C

30% Higher Throughput vs. traditional round wire belts

Certifications:

√ ISO 9001:2015 | √ FDA 21 CFR 177.2600 | √ EHEDG EL Class

Technical Advantage

√ Precision Engineering

Flat wire thickness: 0.8-4.0mm (customizable)

Surface flatness tolerance: ±0.05mm/m

Edge welding strength: 90% of base material

√ Extreme Environment Ready

314 SS for high-temp furnaces (up to 800°C)

316L SS for corrosive washdown (pH 1-14)

√ Hygienic Design

Electropolished finish (Ra ≤0.4μm)

Open area: 15-80% for airflow/cooling optimization

Application Scenarios

| Industry | Application | Huada Solution |

| Electronics | PCB Soldering & Testing | ESD-safe coating (10⁶-10⁹Ω) |

| Food Processing | Cookie Baking Lines | Non-stick PTFE-free coating |

| Automotive | Precision Stamping Transfer | 4.0mm thickness for 50kg/m² |

| Pharmaceutical | Tablet Coating & Drying | CIP-ready 316L SS design |

Technical Parameters

| Parameter | Huada Flat Wire Belt | Industry Standard |

| Surface Roughness | Ra ≤0.4μm (mirror polish) | Ra ≥1.2μm |

| Load Capacity | 50 kg/m² (4.0mm thick) | 30 kg/m² |

| Temperature Range | -40°C to 800°C | -20°C to 600°C |

| Cleaning Cycle Time | 15 minutes (CIP ready) | 30+ minutes |

Case Study: Global Electronics Manufacturer

Huada’s flat wire belts solved our PCB scrapping issue:

0.02% defect rate (down from 1.5%)

20% faster line speed with precision alignment

Passed ESD S20.20 certification for static control

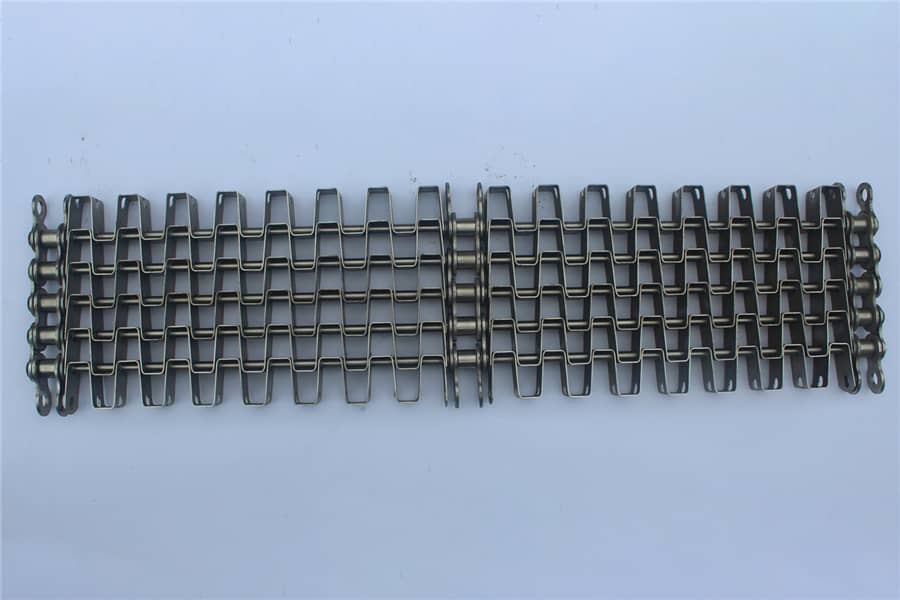

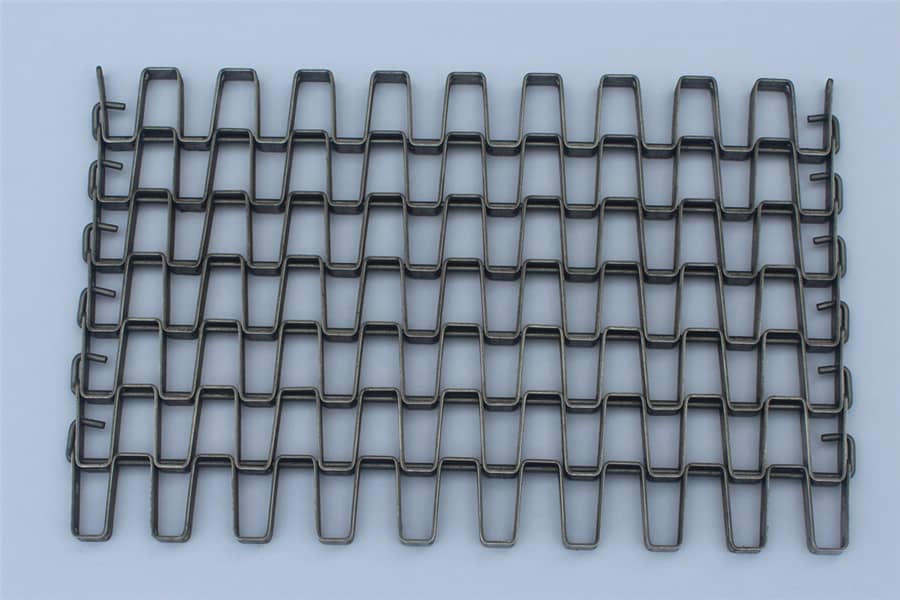

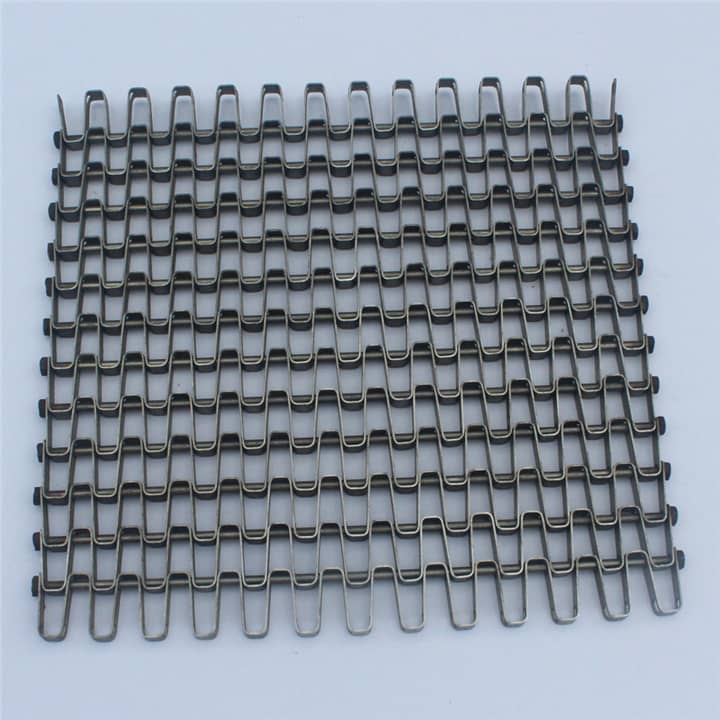

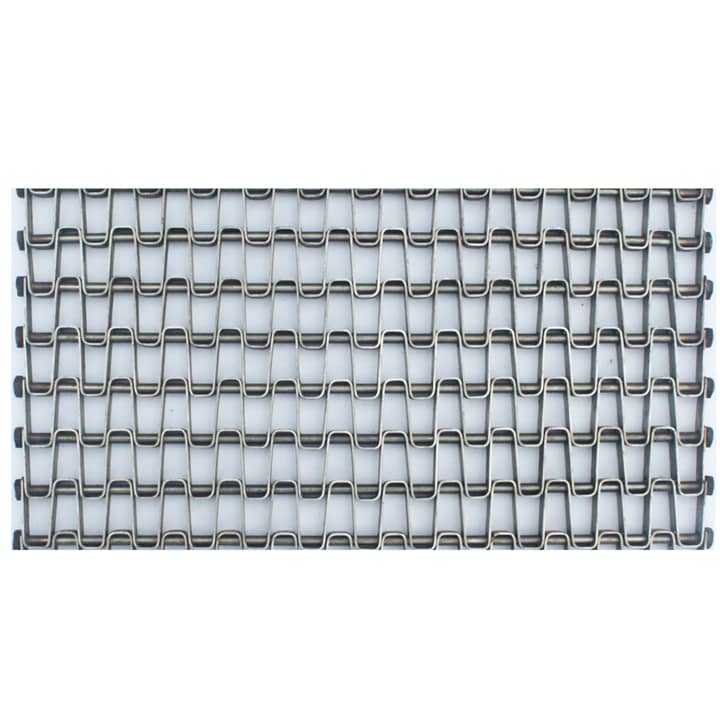

detail pictures