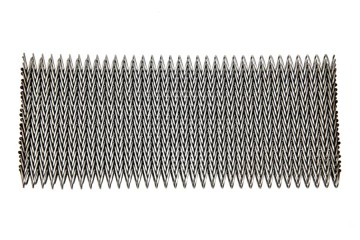

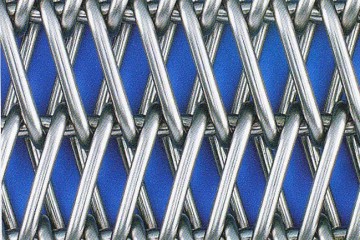

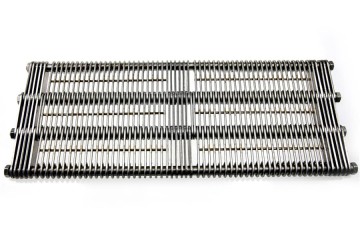

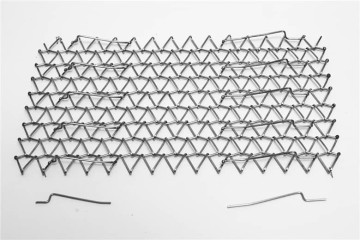

High-Temp Cr20Ni80 Alloy Furnace Belt - Custom ODM Supplier for Reliable Performance

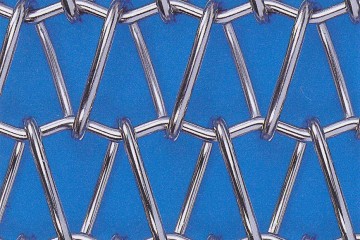

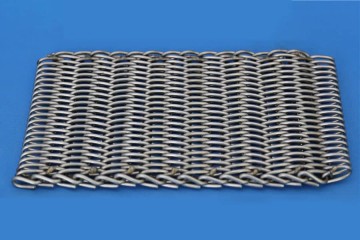

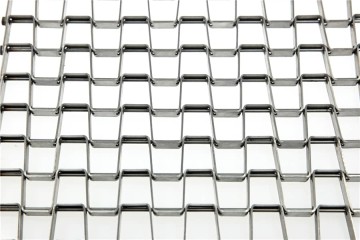

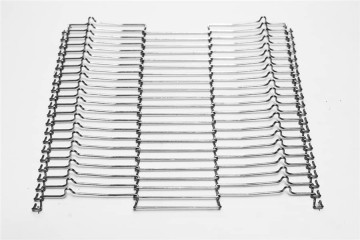

The Hi Temperature Cr20Ni80 Alloy Furnace Belt is an exceptional choice for high-temperature applications. Engineered to endure extreme conditions, these premium belts deliver outstanding durability and operational efficiency in manufacturing processes. We take pride in our commitment to quality and offer competitive discounts for bulk orders, providing businesses with a cost-effective way to invest in superior materials.

Where the Value Lies Hi Temparature Cr20ni80 Alloy Furnace Belt Global Reach Is The Best

In the competitive landscape of industrial manufacturing, finding a reliable partner that delivers quality and innovation is crucial. At JIANGSU HUADA METAL MESH BELT CO., LTD., we stand out as China’s pioneering manufacturer of metal conveyor belts, recognized for our high-performance hair temperature CR20Ni80 alloy furnace belts. With ISO 9001 and CE certifications, we assure our global clients of production quality and safety, vital for maintaining operational efficiency. Our precision-engineered wire Mesh Belts and chain-driven systems have already reached over 20 countries across five continents, establishing us as a trusted supplier in various industries. The unique properties of our CR20Ni80 alloy belts make them perfect for high-temperature applications, providing durability and reliability in challenging environments. By choosing HUADA, you benefit from not only superior products but also a commitment to customer satisfaction and technical support that ensures optimal performance. As industries continue to evolve, having a partner like HUADA helps you stay ahead of the competition. Our innovative solutions tailored to meet specific operational needs empower your business for success in today’s global marketplace. Connect with us to explore how our offerings can add value to your production processes.

Where the Value Lies Hi Temperature Cr20Ni80 Alloy Furnace Belt Global Reach Is The Best

| Parameter | Value | Unit | Application |

|---|---|---|---|

| Density | 8.1 | g/cm³ | Furnace Belts |

| Melting Point | 1400 | °C | High Temperature Applications |

| Tensile Strength | 550 | MPa | Load Bearing |

| Thermal Conductivity | 16 | W/m·K | Heat Resistance |

| Corrosion Resistance | Good | - | Extended Durability |

| Width | 20 | cm | Custom Fit |

| Typical Applications | Heat Treatment | - | Industrial Furnaces |

Trending Hi Temparature Cr20ni80 Alloy Furnace Belt Application Supplies the World’s Top Brands

R

Robert Wilson

The quality speaks for itself. Moreover, the professionalism of the after-sales team was commendable.

05 July 2025

P

Patricia Carter

A great investment! The after-sales support showed amazing commitment and expertise.

08 July 2025

W

William Cooper

High-quality goods that truly deliver! The customer service team was exceptional.

11 May 2025

M

Matthew Lee

I love the quality of this product! The service team was very professional and courteous.

21 May 2025

M

Michael Clark

Very satisfied with my purchase! The quality and service level are remarkable.

20 May 2025

A

Angela Hayes

An excellent experience! The product quality is impressive, and the after-sales service was stellar.

26 May 2025