Premium Low Thermal Expansion Weave Belt - ODM Manufacturer & Supplier Solutions

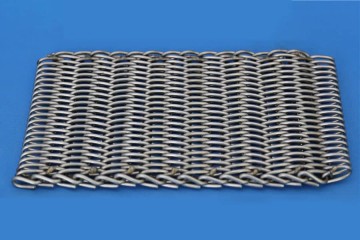

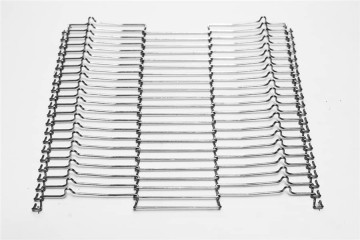

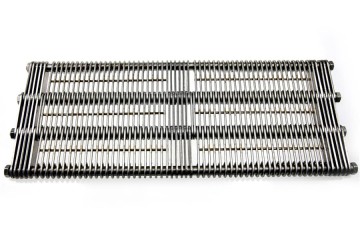

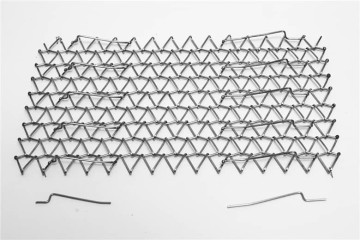

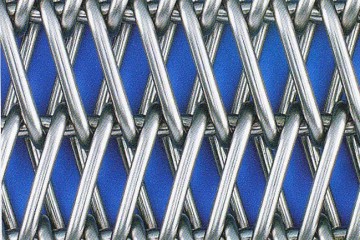

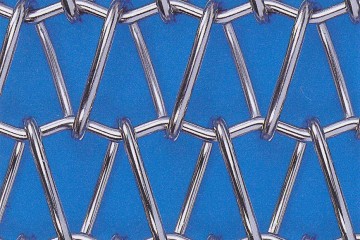

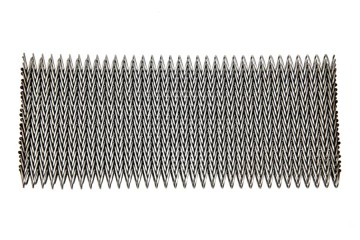

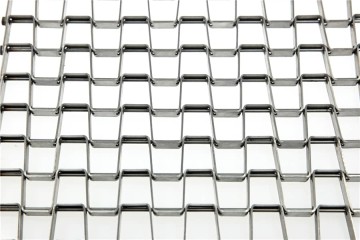

The Low Thermal Expansion Weave Belt from JIANGSU HUADA METAL MESH BELT CO., LTD is crafted for exceptional efficiency and durability in demanding industrial environments. This advanced belt is engineered to withstand high temperatures, ensuring minimal expansion and contraction during operation. CE certified, it meets stringent safety and quality standards, making it a reliable choice for precision-driven processes. The sturdy design ensures long-lasting performance, reducing the need for maintenance and downtime. Whether upgrading existing systems or integrating new machinery, this weave belt is an ideal solution for challenging conditions, backed by a reputable manufacturer known for its reliability in the industry.How Chinese Manufacturers Low Thermal Expansion Weave Belt Where Service Meets Innovation Trusted by Pros

In the dynamic landscape of global manufacturing, the demand for high-performance materials is ever-increasing. JIANGSU HUADA METAL MESH BELT CO., LTD., as a pioneering force in China’s Metal Conveyor belt industry, stands at the forefront of innovation with its precision-engineered wire mesh belts. Designed specifically for low thermal expansion applications, HUADA’s products are a testament to our commitment to quality and service, trusted by professionals across over 20 countries. Our advanced manufacturing processes and ISO 9001 and CE certified facilities guarantee that each belt is crafted with the utmost attention to detail, ensuring optimal performance under varying operational conditions. The low thermal expansion properties of our weave belt technology provide significant advantages, particularly in industries where temperature fluctuations can compromise productivity. These belts not only enhance the reliability and longevity of your production systems but also contribute to overall efficiency, making them an invaluable choice for global procurement professionals. When partnering with HUADA, clients gain access to cutting-edge solutions that marry service with innovation. Our dedicated team is committed to providing exceptional support, helping you navigate the complexities of selecting the right conveyor solutions tailored to your unique operational needs. Experience the difference of working with a manufacturer that prioritizes excellence and fosters innovation in every aspect of its offerings. Let us help you elevate your manufacturing capabilities with our trusted metal conveyor belts.

How Chinese Manufacturers Low Thermal Expansion Weave Belt Where Service Meets Innovation Trusted by Pros

| Model | Material | Temperature Tolerance (°C) | Expansion Coefficient (10^-6/K) | Applications |

|---|---|---|---|---|

| Model A | Polyester | -20 to 150 | 8 | Textile Industry |

| Model B | Nylon | -30 to 180 | 7 | Automotive |

| Model C | PTFE | -50 to 260 | 4 | Chemical Processing |

| Model D | Silicone | -40 to 200 | 6 | Medical Devices |

| Model E | Kevlar | -50 to 300 | 5 | Aerospace |

How To Compare Low Thermal Expansion Weave Belt Delivers Unmatched Quality Stands Out

M

Matthew Martinez

Great product quality paired with outstanding service. I felt valued as a customer!

21 May 2025

S

Sarah Martin

I am thrilled with my purchase! The quality is excellent, and the service team was outstanding.

09 May 2025

T

Thomas Adams

Incredible quality! My experience with the customer service team was nothing short of perfect.

22 May 2025

L

Linda Scott

Thrilled with the product! The professionalism of the support staff raised the bar for service.

08 May 2025

D

Daniel Martinez

Very satisfied! The quality is evident, and the support team was fantastic.

02 June 2025

N

Natalie Martinez

High-quality product! The support team’s expertise made the entire process smooth.

22 May 2025