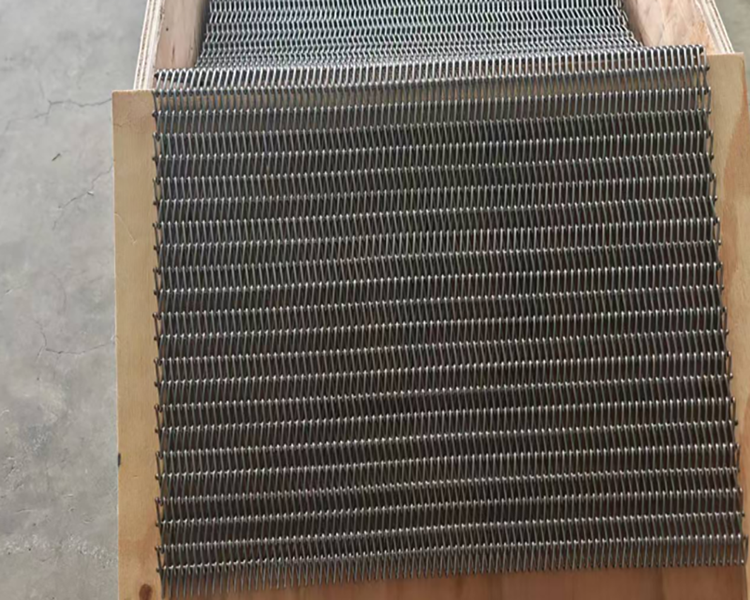

New Delivery of Custom Solar Dryer Mesh Belts to Leading Vietnamese Photovoltaic Manufacturer

Yangzhou, China – Aug 18th, 2025 – HUADA MESH BELT, a pioneer in industrial thermal Processing Equipment, has supplied 316L stainless steel oven mesh belts to a cutting-edge Vietnamese photovoltaic (PV) facility—part of a Chinese solar industry leader’s overseas expansion. This shipment underscores the growing global demand for high-performance, durable solutions in solar manufacturing, even as geopolitical shifts drive supply chain diversification.

Rising Tide of Overseas Solar Manufacturing

Driven by U.S. trade policies and energy security concerns, over 70% of China’s top PV manufacturers—including LONGi, Jinko Solar, and Trina Solar—have established production hubs in Southeast Asia since 2020.

Vietnam, with its competitive labor costs and 2,700+ annual sunshine hours, has emerged as a critical node in this expansion. Our Vietnamese client, a subsidiary of a Fortune Global 500 solar enterprise, exemplifies this trend, leveraging Vietnam’s FIT incentives and proximity to ASEAN markets to optimize production costs.

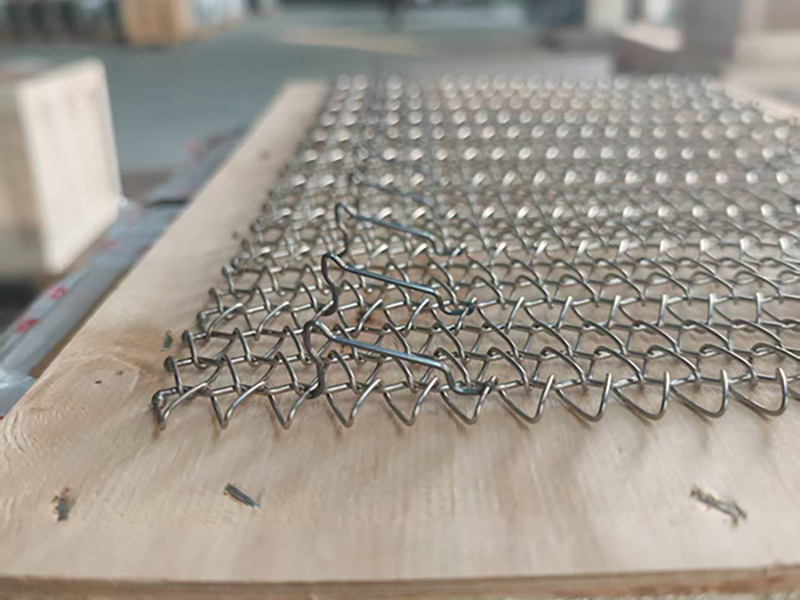

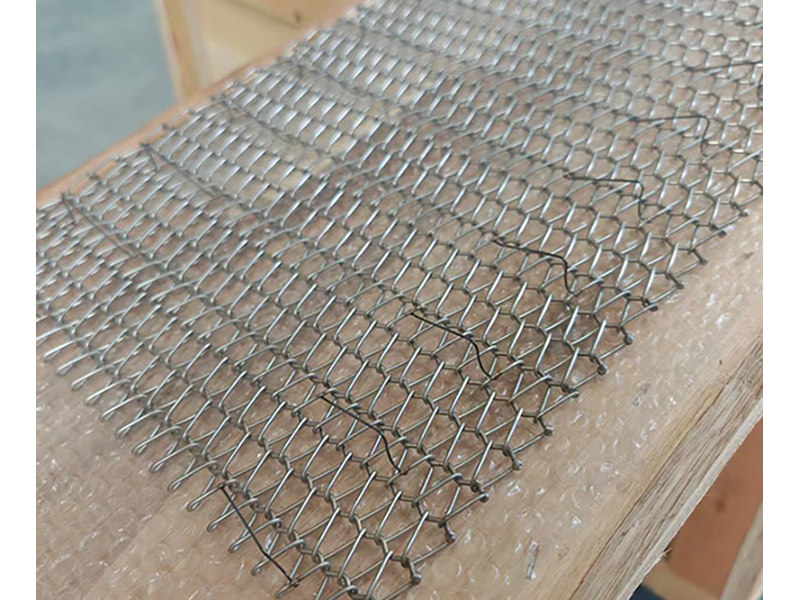

Technical Breakdown of Our Solar Dryer Mesh Belts

The 316L stainless steel oven mesh belts are engineered for extreme durability in solar cell drying applications:

- Material: 316L stainless steel with 200% higher corrosion resistance than 304 grade, critical for humidity-prone drying environments.

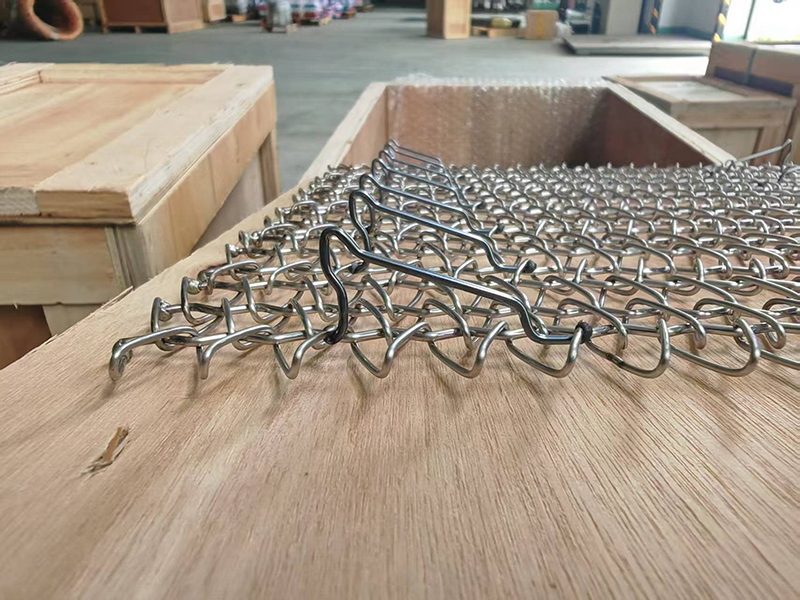

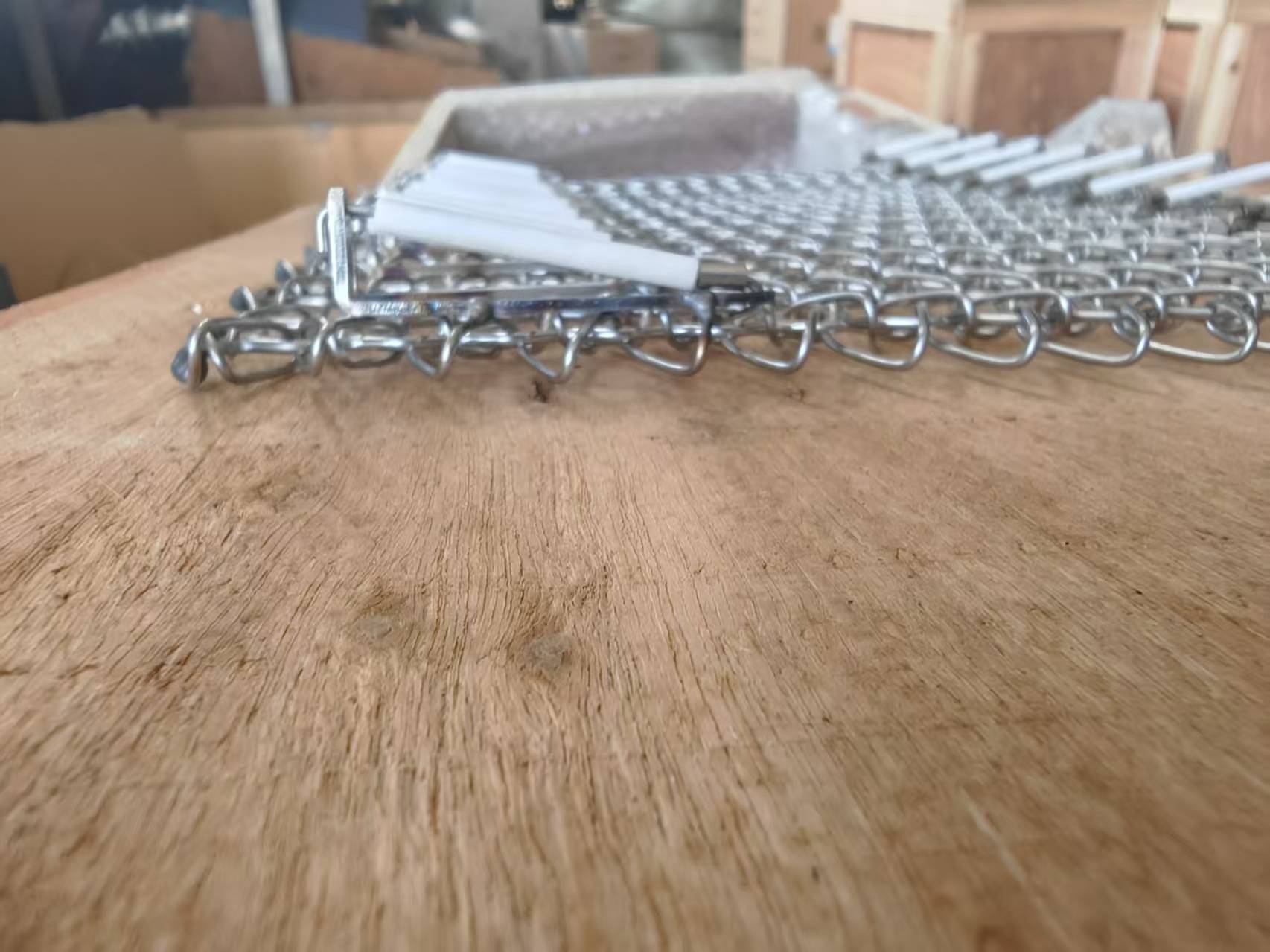

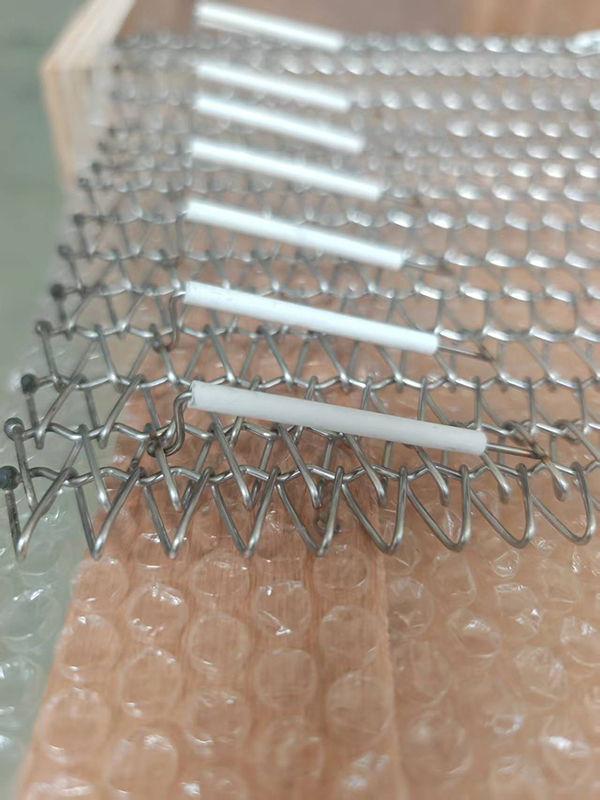

- Custom Standoff Design: Reinforced ceramic-coated standoffs (spaced at 50mm intervals) minimize wear from abrasive solar cell coatings.

- Thermal Stability: Maintains structural integrity up to 750°C, aligning with high-temperature drying cycles (80–150°C) in solar cell production.

- Precision Geometry: 2mm wire diameter and 12.35mm pitch optimize airflow for uniform drying while reducing energy consumption by 15%.

Why Global Solar Manufacturers Choose Us

Proven Compatibility:

Our belts integrate seamlessly with Maxwell, Fulongwin, and Applied Materials drying systems, validated by 12+ PV clients including REC Group and Q CELLS.

Customization Expertise:

Adjustable standoff patterns and ceramic sleeve options to prevent coating adhesion—a common issue in PERC and TOPCon cell production.

Case Study: Streamlining Vietnamese Solar Production

- 20% Yield Improvement: Ceramic-coated standoffs reduced belt replacement frequency from 3 months to 6

- Energy Savings: Optimized airflow design cut drying cycle times by 22%, saving 1.2M kWh annually.

- Zero Defect Compliance: Smooth surface finish minimized particle contamination during anti-reflective coating application.

Navigating Geopolitical Challenges in Solar Manufacturing

While U.S. Section 201 tariffs and anti-circumvention probes target Southeast Asian imports, our clients prioritize localization compliance:

Dual-Certified: ISO 9001 and IATF 16949 certifications ensure seamless integration into global supply chains.

Global Logistics Network: Efficient shipping from our factory to Southeast Asia in 5-7 days, with air freight and express courier options.

Future-Proofing Solar Infrastructure

As Vietnam aims for 4GW of annual solar capacity by 2025, we’re scaling production of dryer mesh belts to meet surging demand.

Join the Global Solar Revolution

HUADA MESH BELT invites solar manufacturers worldwide to experience precision-engineered oven mesh belts that redefine efficiency. For OEM collaborations or bulk orders, contact:

📧 jerry@meshbelt.cn | 📞 +86 187 6231 1618

🌐 site_5692daef-da17-420f-94c5-497c98eb8172

About HUADA MESH BELT

Since 1992, HUADA MESH BELT has specialized in thermal processing solutions for solar, electronics, and aerospace industries.

SEO Keywords: oven mesh belt, dryer mesh belt, dryer Metal Belt, dryer oven conveyor belt, Transport belt for solar cell dryer, 316L solar belt, ceramic-coated standoff, PV drying equipment.