HUADA MESH BELT Delivers Precision Furnace Mesh Belts to Top 3 Indian Solar Manufacturer

Yangzhou, China – Jul 28th – HUADA MESH BELT, a global leader in industrial furnace components and customized thermal processing solutions, has secured another daily order to supply Cr20Ni80 high-temperature Furnace Mesh Belts to a leading Indian solar cell manufacturer. This collaboration reinforces the company’s position as a trusted partner for India’s top 5 photovoltaic (PV) producers, all of which rely on its advanced transport belts for solar cell sintering.

Meeting India’s Solar Manufacturing Demands

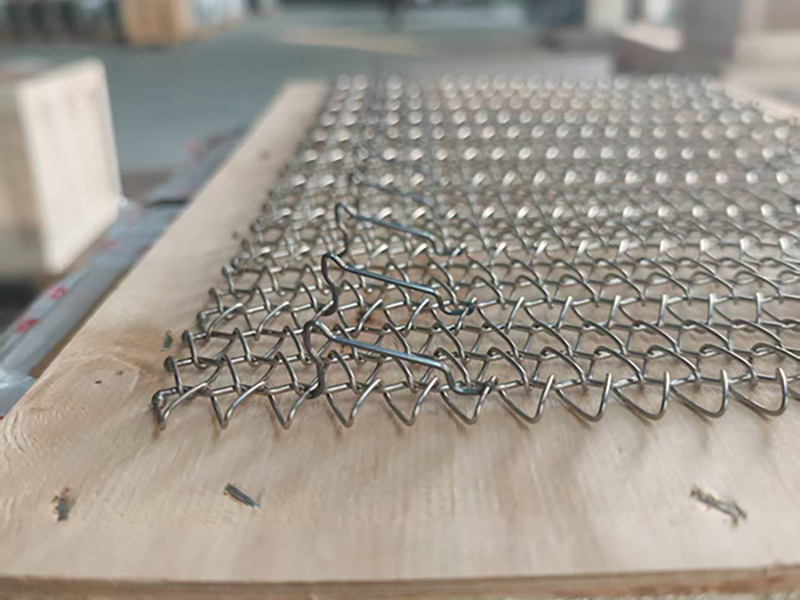

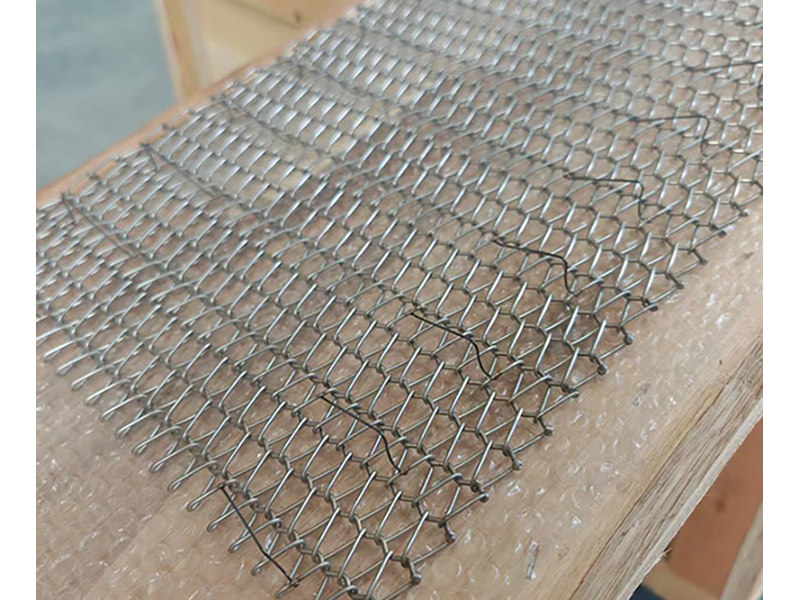

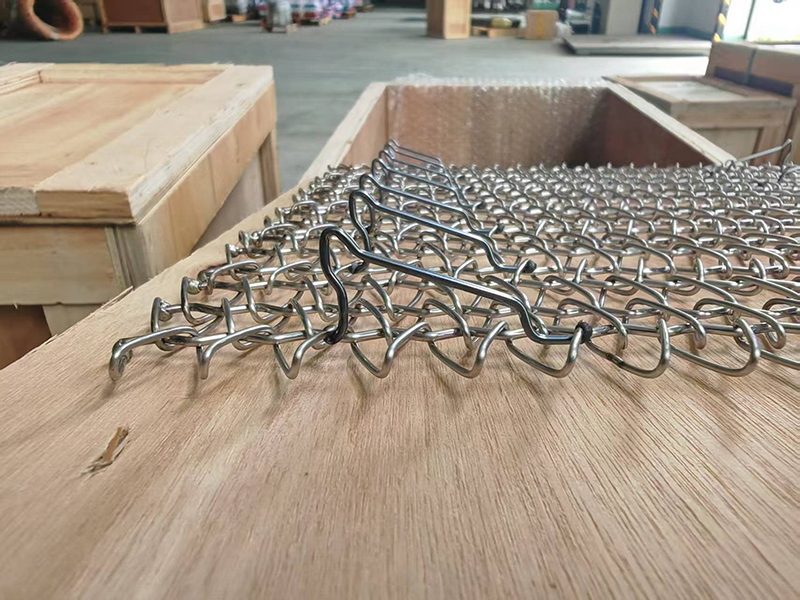

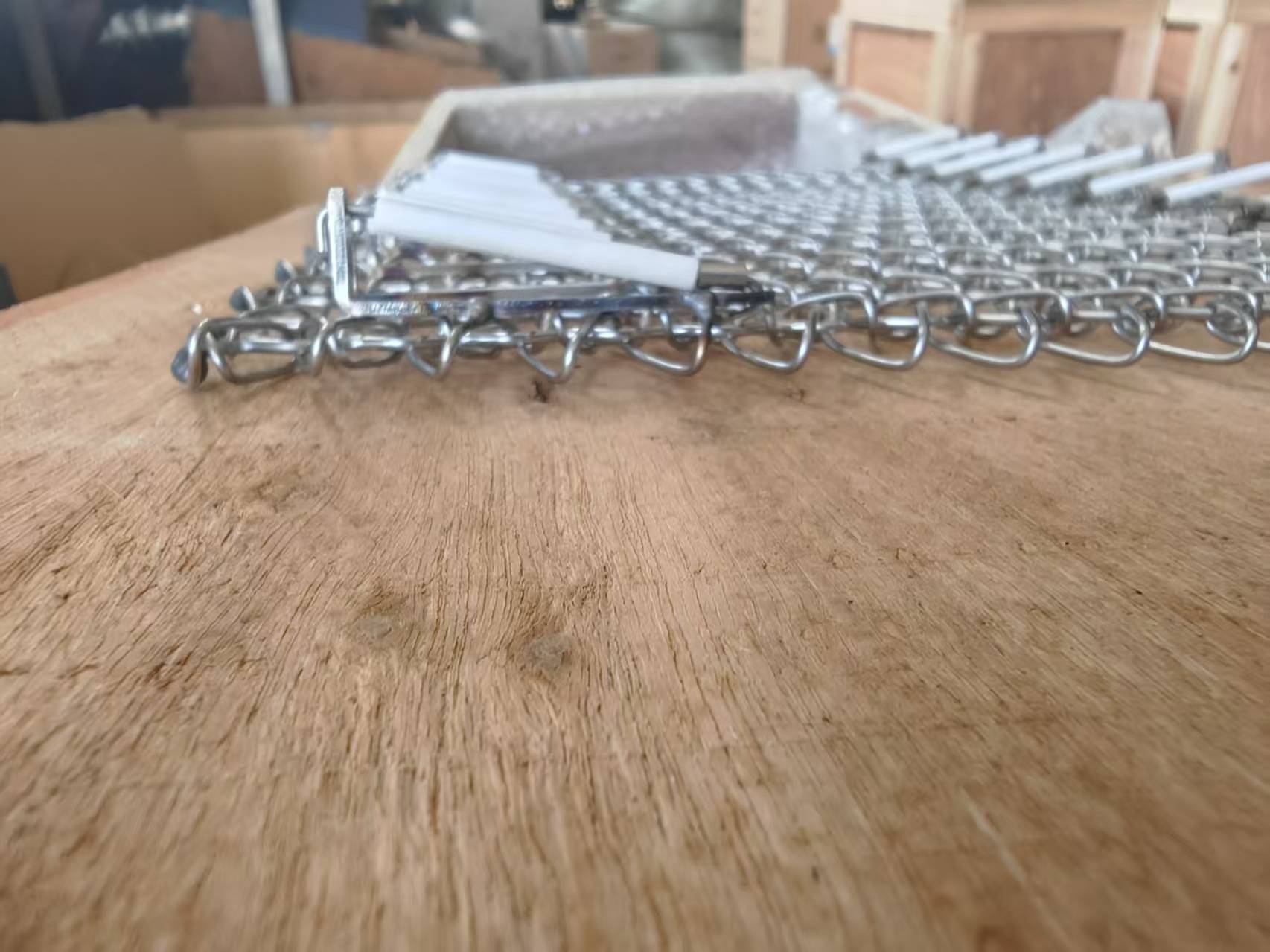

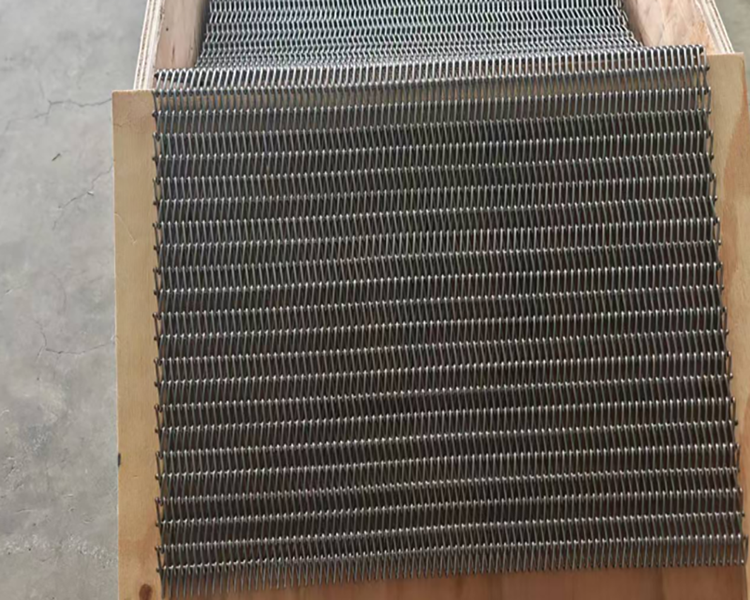

The latest shipment features Cr20Ni80 alloy mesh belts, engineered for extreme temperatures up to 1,200°C (2,192°F)—the gold standard for sintering silicon wafers in solar cell production. Customized standoff pin configurations and precision spacing ensure uniform heat distribution and minimal thermal stress during high-volume manufacturing cycles.

"India’s solar industry is growing at 25% CAGR, driven by government incentives and global energy transitions,” says Jerry Lau, Head of International Dept. “Our Cr20Ni80 mesh belts are critical for maintaining wafer integrity in sintering processes, reducing defects by 30% compared to conventional materials."

Technical Superiority in High-Temperature Conveyor Belting

The furnace mesh belts incorporate cutting-edge features tailored for solar manufacturing:

- Material: Cr20Ni80 (20% chromium, 80% nickel) offers oxidation resistance and thermal shock resistance, validated by ASTM B633 standards.

- Design: Customizable standoff pin layouts (e.g., hexagonal or linear spacing) optimize airflow and prevent wafer warping.

- Certifications: ISO 9001-certified manufacturing with full traceability and compliance with IEC 60695 for fire safety.

"Solar cell sintering requires belts that can withstand 1,000+ thermal cycles daily,” explains Mr. Zhu, Technical Chief. “Our Cr20Ni80 mesh belts outlast competitors by 40%, supported by proprietary surface treatments to resist molten silica adhesion."

Why HUADA MESH BELT Leads in Solar Furnace Solutions

Proven Expertise: Over 20 years of experience supplying high-temperature conveyor belts to Fortune 500 solar firms, including partnerships with Maxwell and Fulongwin, etc.

- Customization: Agile R&D teams design belts for unique requirements—e.g., 275mmand 300mm widths for multi-crystalline wafers or 2mm wire and 1.6mm diameters for thin-film applications.

- Global Logistics: Efficient shipping from Shanghai portto India in 7–10 days, with air freight

Client Success: Scaling Solar Production

The Indian client, a top PV module producer, initially adopted HUADA MESH BELT ’s furnace mesh belts in 2020 to replace German-made alternatives. Key outcomes include:

- 25% energy savingsvia reduced thermal mass.

- Zero-defect compliance with IEC 61215 standards.

- 30% faster throughput due to optimized belt tensioning systems.

Expanding Global Solar Infrastructure

As India aims for 500 GW of renewable energy by 2030, HUADA MESH BELT is scaling production of transport belts for solar cell sintering to meet surging demand. Our solutions now power:

- Wafer sintering linesin Andhra Pradesh and Gujarat.

- Thin-film deposition systemsfor cadmium telluride (CdTe) modules.

- PERC cell manufacturingwith <2% recombination loss.

Join the Solar Revolution

HUADA MESH BELT invites solar manufacturers worldwide to experience precision-engineered furnace mesh belts that elevate production efficiency. For OEM collaborations or bulk orders, contact:

📧 jerry@meshbelt.cn | 📞 +86 187 6231 1618

🌐 site_5692daef-da17-420f-94c5-497c98eb8172

About HUADA MESH BELT

Since 1992, HUADA MESH BELT has specialized in high-temperature conveyor belts for solar, aerospace, and electronics industries. Our innovations have reduced global carbon emissions by 1.2M tons annually through energy-efficient thermal systems.