First Order from a Leading Indian Glass Company: A Testament to Quality and Reliability

Yangzhou City, China – Oct 8th – Quality products create their own marketing through customer satisfaction and repeat business.

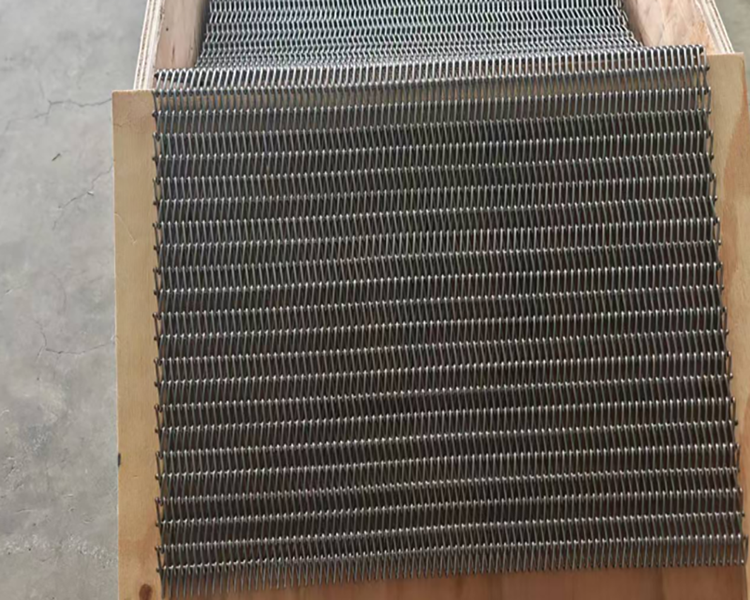

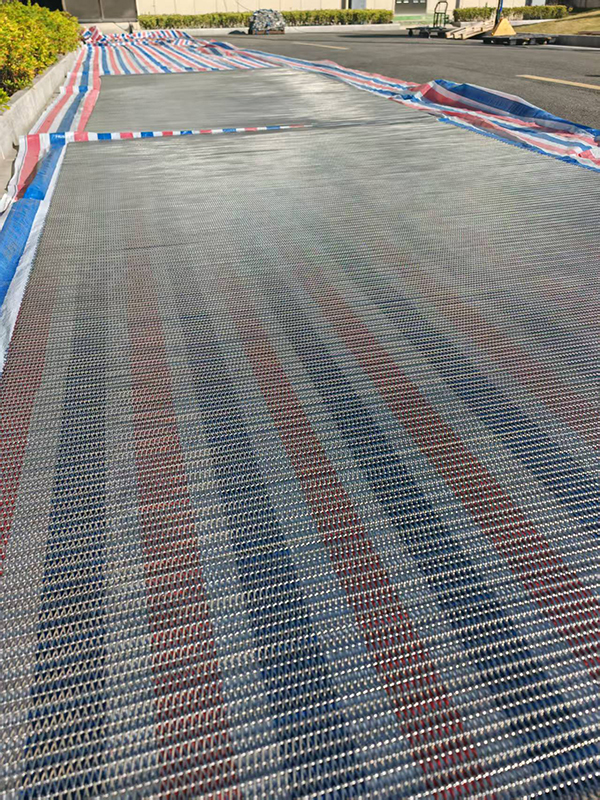

In a significant endorsement of our product excellence, we recently received an immediate first order for 200 meters of 2600mm wide 316L Furnace Mesh Belt from a prominent Indian glass company. This order came through a direct recommendation from their sister enterprise, which had previously tested our products and been thoroughly impressed with their performance. The trusting client skipped the trial phase entirely, moving straight to production implementation—a powerful testament to the established reputation of our high-temperature conveyor solutions.

The Power of Recommendation in Specialty Industrial Equipment

The industrial glass sector operates on principles of reliability and proven performance. When one division of a leading Indian glass manufacturer tested our high-temperature conveyor belt in their production line, the results were compelling enough that they immediately recommended our solution to their sister company. This type of endorsement carries significant weight in an industry where downtime can cost thousands per hour.

What makes this endorsement particularly remarkable is the client's confidence in bypassing the typical trial phase. They understood that our specialized furnace mesh belt would deliver consistent performance based on their sister company's documented experience with longer service life, reduced maintenance requirements, and enhanced operational efficiency.

Technical Excellence: Meeting Rigorous Glass Industry Standards

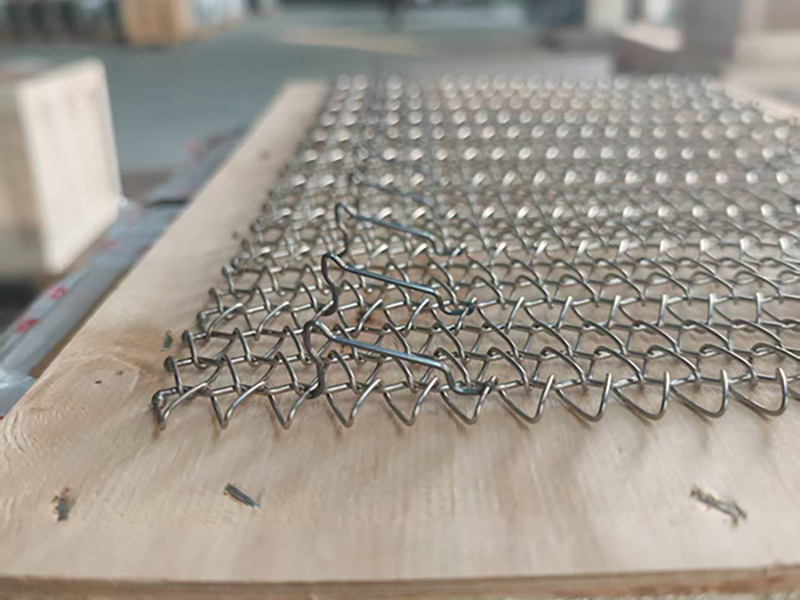

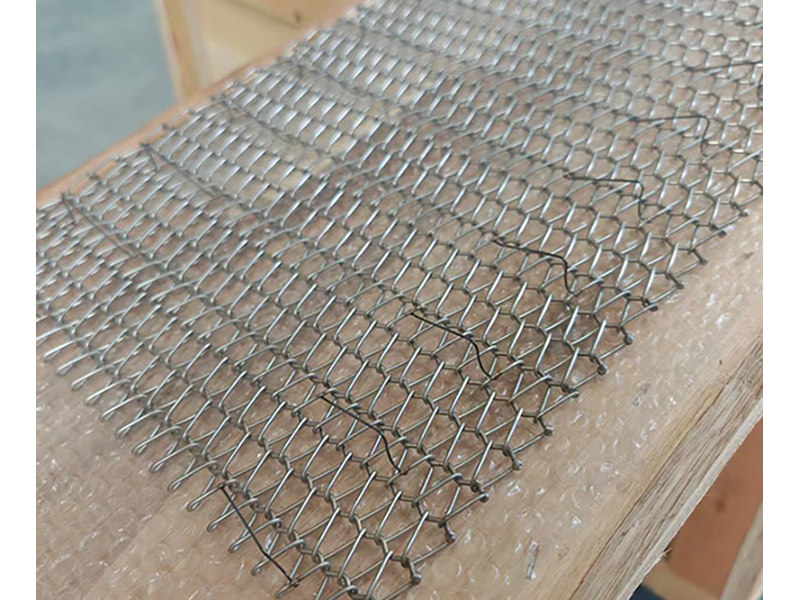

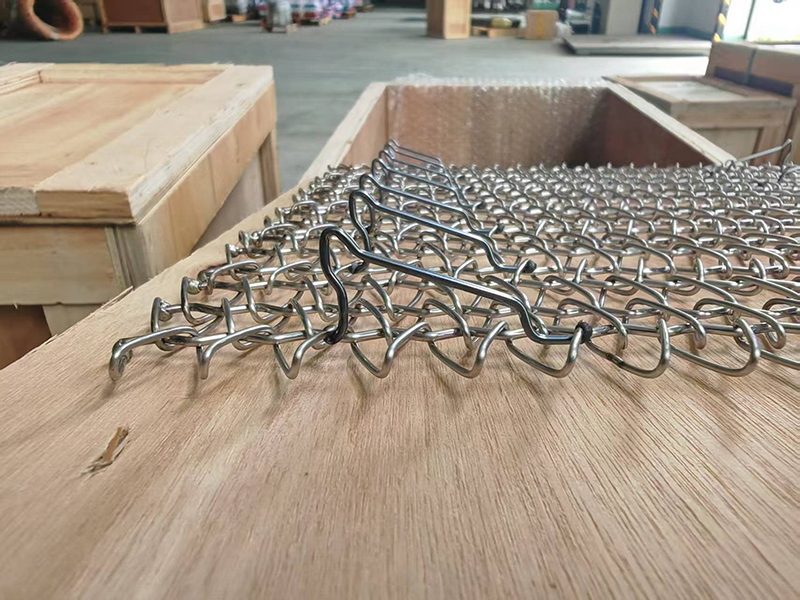

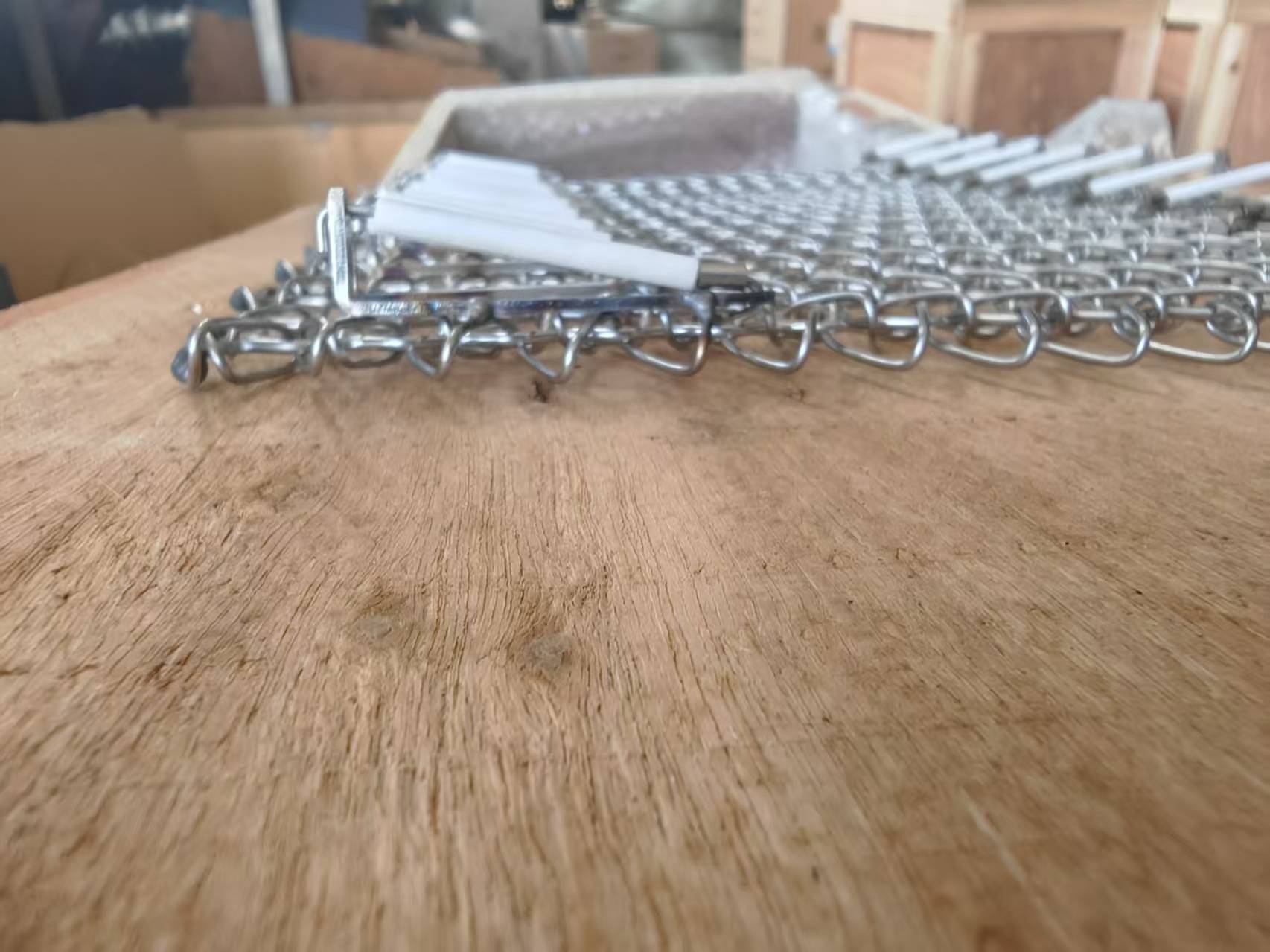

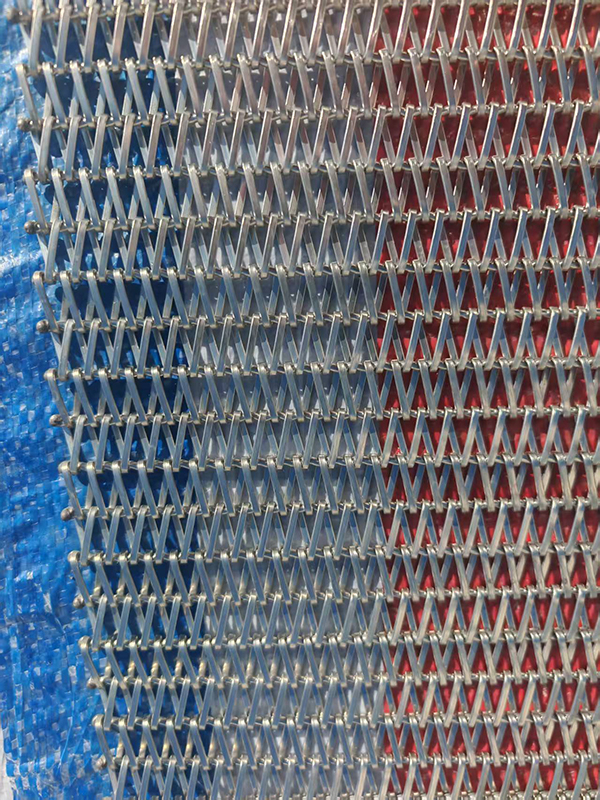

The ordered conveyor system—a 316L Stainless Steel Mesh belt measuring 200 meters in length and 2600mm in width—represents one of our flagship products designed specifically for demanding glass manufacturing environments. The selection of 316L material offerssuperior resistance to high temperatures and corrosive atmospheres, essential for maintaining integrity in continuous glass production operations.

We offer a range of high-grade materials to suit various operational requirements in the glass industry:

- AISI 314: Exceptional high-temperature resistance, ideal for applications exceeding 1000°C

- SUS 316L: Superior corrosion resistance, perfect for environments with thermal cycling

- SUS 304: Cost-effective solution for less demanding applications

Each material provides distinct advantages depending on specific operational parameters, including maximum temperature exposure, thermal cycling frequency, atmosphere conditions, and load requirements. Our technical team works closely with clients to determine the optimal material selection for their unique operating conditions.

Critical Applications in Glass Manufacturing

Furnace mesh belts serve indispensable roles throughout the glass production process, particularly in thermal treatment applications where precision and reliability are paramount.

Glass Annealing Processes

Mesh belts for glass annealing operate within lehr furnaces where newly formed glass products undergo controlled cooling to relieve internal stresses. Our conveyor systems maintain precise temperature distribution across the belt surface, ensuring uniform thermal treatment for consistent product quality. The smooth, stable surface of our belts prevents marking or distortion of glass products during this critical phase.

Sintering and Forming Operations

In sintering applications, conveyor belts for sintering furnace transport glass powders through high-temperature zones where particles bond to form solid materials. Our belts' open mesh structure promotes uniform heat distribution, while their high-temperature resistance ensures dimensional stability under thermal stress.

Thermal Strengthening and Tempering

For tempered glass production, our conveyor systems withstand the extreme temperature fluctuations inherent in the quenching process, maintaining structural integrity while providing consistent product transport.

Engineering Superiority: Why Our Belts Outperform

The exceptional performance of our high-temperature conveyor belts stems from deliberate engineering choices and quality-focused manufacturing processes

Enhanced Durability and Longevity

Customer feedback consistently highlights our belts' extended service life compared to conventional offerings. This durability translates directly to reduced replacement frequency, lower maintenance costs, and decreased production downtime. One client reported a 40% increase in operational life compared to their previous supplier's product.

Precision Manufacturing for Consistent Performance

Our belts feature uniform mesh structures that ensure consistent product support and heat distribution across the entire belt surface. The precise welding of connecting rods and spirals creates a robust structure resistant to deformation under heavy loads at elevated temperatures

Thermal Stability Under Extreme Conditions

The specific materials we employ maintain structural integrity at temperatures exceeding 1000°C, with minimal thermal expansion that prevents buckling or distortion during operation. This stability is crucial for maintaining precise alignment within conveyor systems.

The Global Reach of Quality Products

While our recent success with the Indian glass industry represents a significant milestone, it reflects a broader pattern of international satisfaction with our products. We've supplied high-temperature conveyor solutions to glass manufacturers across Asia, Europe, and the Americas, with each market validating the universal reliability of our offerings. As we continue to expand our global reach, we remain committed to the principles that have driven our success: engineering excellence, material superiority, and unwavering dedication to customer satisfaction. The unsolicited endorsement from our Indian client—resulting in an immediate 200-meter order—demonstrates that quality products ultimately create their own marketing through customer satisfaction.

Conclusion: Partnering for Production Excellence

The confidence placed in us by the Indian glass manufacturer reflects the growing recognition of our products as premium solutions for demanding high-temperature applications. As we move forward with this partnership, we remain committed to supporting the global glass industry with conveyor products that deliver uncompromising quality, extended service life, and optimal operational efficiency.

For glass manufacturers seeking to enhance their production capabilities through superior thermal processing equipment, our specialized conveyor solutions offer the reliability and performance demanded by modern manufacturing challenges. Contact our technical team to discuss how our high-temperature conveyor belts can optimize your glass manufacturing processes.

📞 +86 187 6231 1618 | 📧 jerry@meshbelt.cn

🌐 site_5692daef-da17-420f-94c5-497c98eb8172