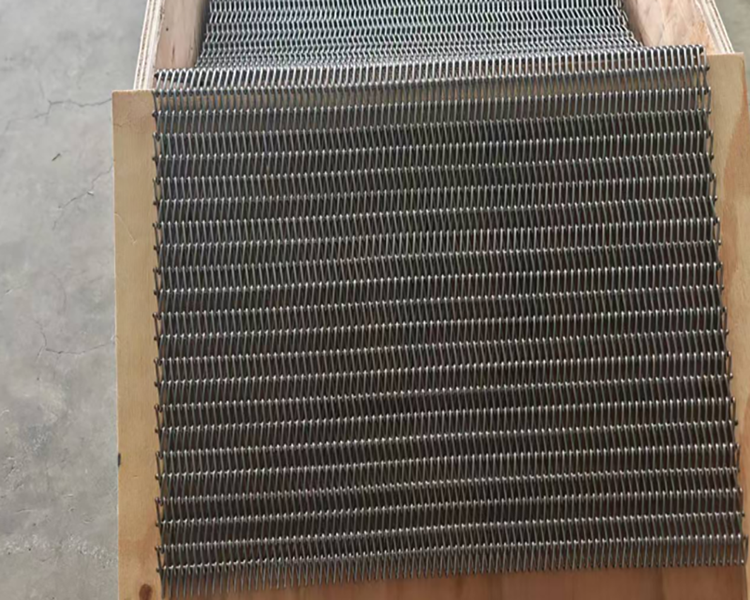

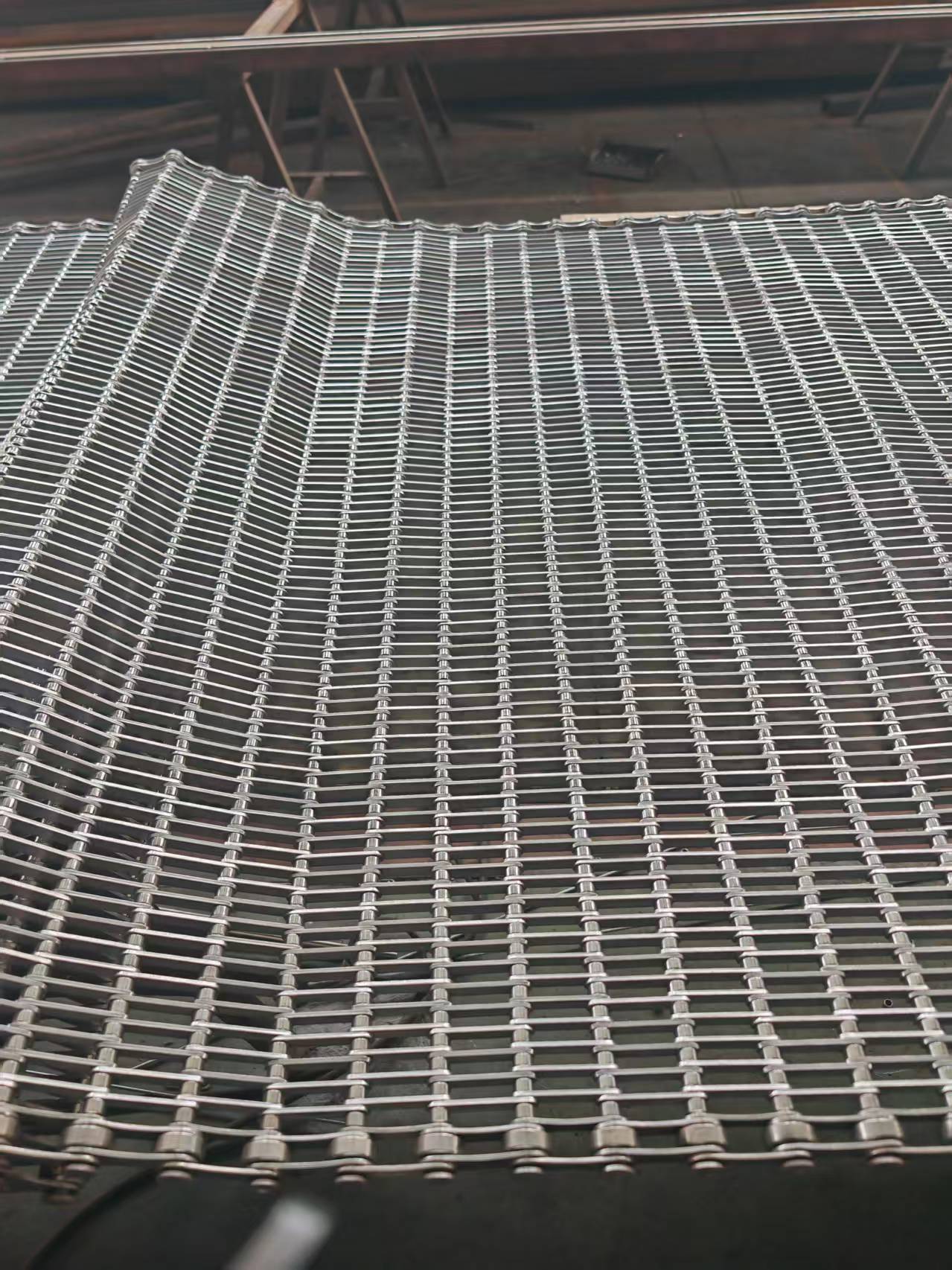

Huada Mesh Belt Supplies Heavy-Duty SUS 304 Conveyor Belt to Global Industrial Solutions Leader for Abrasion-Intensive Processes

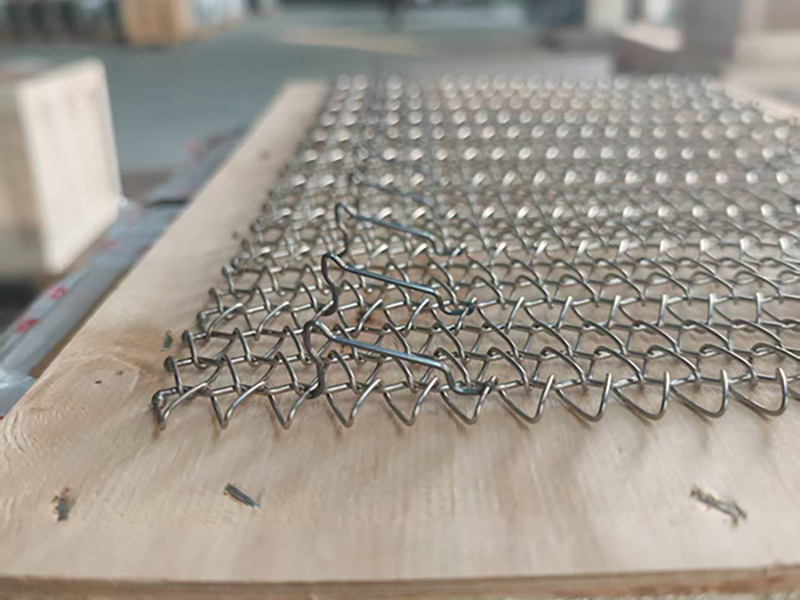

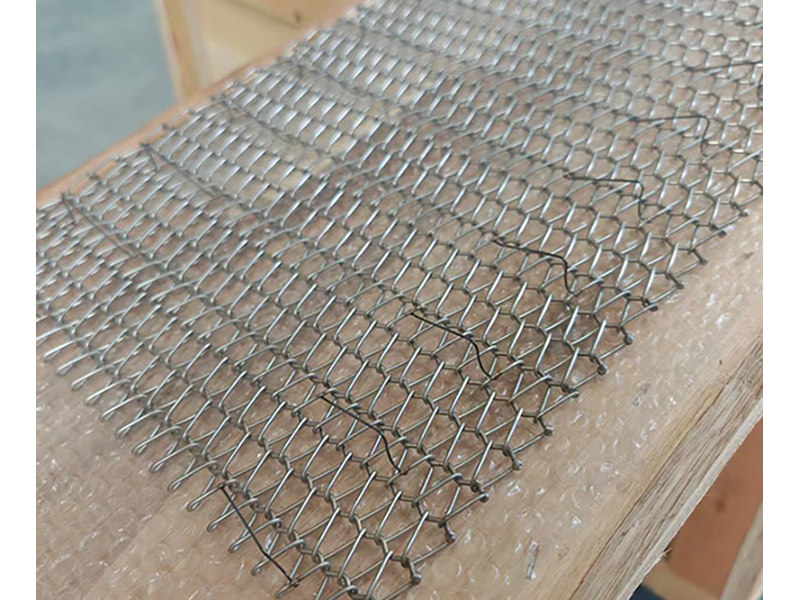

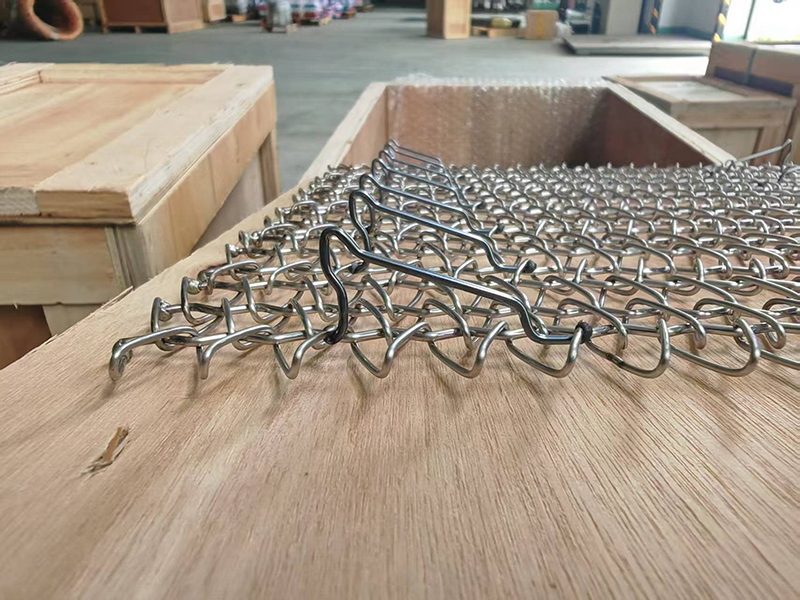

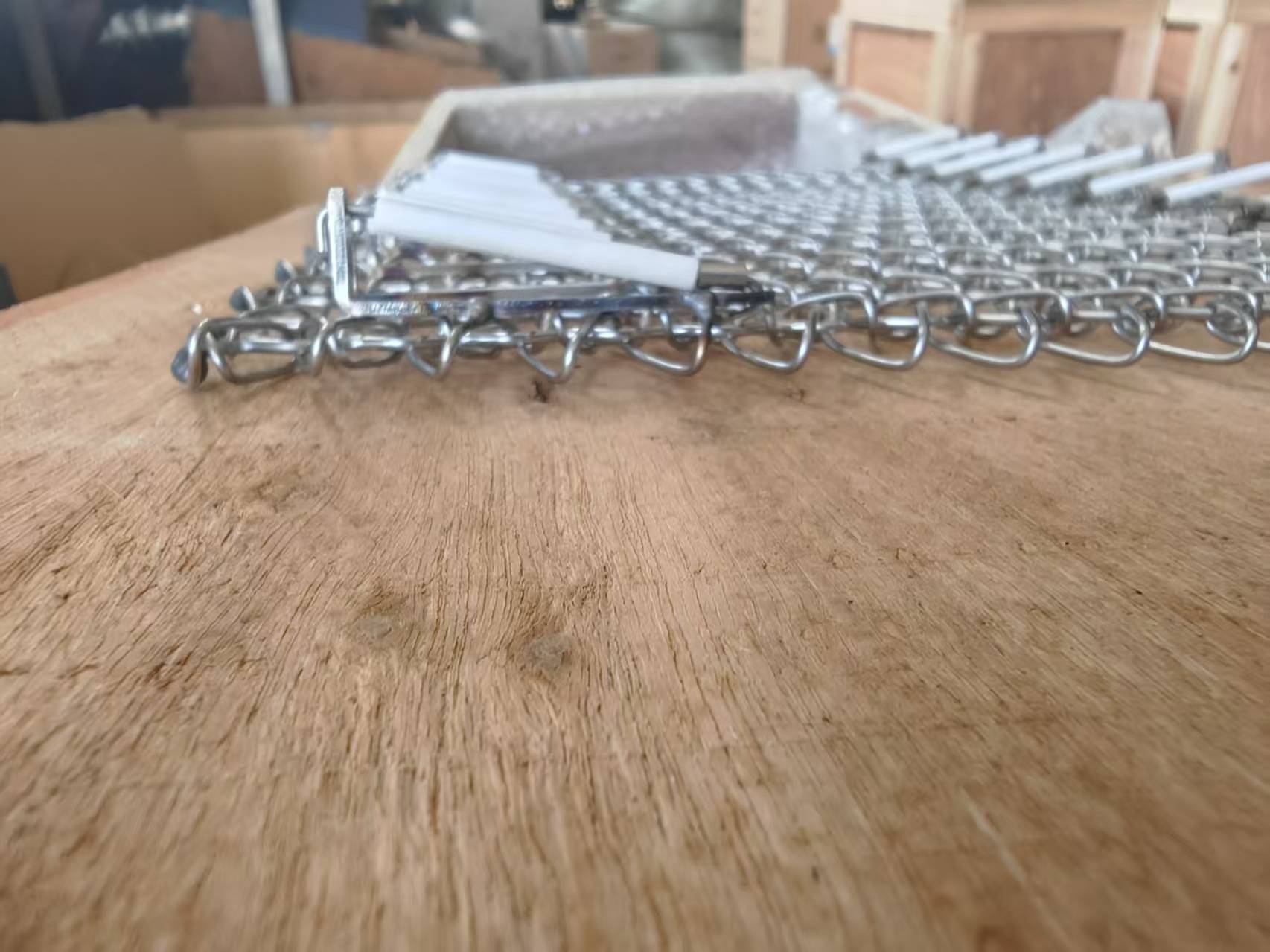

BANGKOK, THAILAND – June 18, 2025 – Huada Mesh Belt has delivered a custom-engineered SUS 304 Industrial Conveyor Belt to a global industrial technology leader in Bangkok, Thailand. Designed for extreme mining environments, the system features 3.25mm stainless steel bushes, 8.0mm cross rods, and HB50.8 drive chains – directly supporting the client’s mineral processing operations.

Engineered for Triple Wear Resistance

The belt addresses critical industry challenges documented in the client’s case studies:

· Abrasion Resistance: HB50.8 chains withstand >12mm particle impacts (extending service life 40% vs. standard chains)

· Chemical Resilience: SUS 304 (Cr18Ni9) endures pH 3-11 slurry environments in ore washing systems

· Thermal Stability: 3.25mm bushes maintain structural integrity at 400°C clinker temperatures.

"This shipment reinforces our decade-long partnership with pioneers in comminution technology," stated Huada Mesh Belt’s Chief Engineer. "We’ve supplied critical conveying solutions for their ball cooling lines and crusher discharge systems – each designed to maximize uptime in 24/7 operations."

Seamless Integration with Core Client Applications

The belts support the client’s flagship solutions:

Mineral Processing Optimization

· Integrated with high-wash efficiency ore classifiers (reference: client’s copper recovery case study)

· Reduces maintenance downtime by 30% vs. traditional belts

Sustainable Wear Management

· 100% recyclable SUS 304 material aligns with client’s "Reduce-Reuse" initiatives

· Energy-efficient HB50.8 chains cut drive power consumption by 18%

Advanced Material Handling

· Transports Metal Matrix Composite (MMC) grinding media in cooling stages

· Withstands impact loads exceeding 100kg/m² in aggregate transfer

Synergy with Industrial Innovation

As emphasized in the client’s technical literature, the solution enables:

· Process Reliability: Embedded strain sensors enable real-time tension monitoring (preventing crusher feed interruptions)

· Cost Efficiency: Matches client’s documented 80% wear-part lifetime extension achievement

· Sustainable Operations: Supports client’s goal of 15% carbon reduction in material handling by 2027

Explore our engineering capabilities: site_5692daef-da17-420f-94c5-497c98eb8172/oem-odm/

Contact: jerry@meshbelt.cn | +86 187 6231 1618