Constant Orders from India's Largest PV Company! Complete Sets of High Temperature Mesh Belts for Sintering, LID, and Dryer Oven

Yangzhou City, China – Nov 8th, 2025

In a powerful endorsement of reliability and performance, India's largest photovoltaic (PV) manufacturer has transitioned from an initial trial to a full-scale, multi-line procurement of our specialized mesh belts. After a successful preliminary test of a Sintering Furnace Belt and a dryer oven belt, the client was thoroughly impressed by the exceptional quality and durability that far surpassed cheaper alternatives. This satisfaction led directly to a substantial order for a complete six-month supply of belts for their sintering, Light-Induced Degradation (LID), and dryer oven production lines. This partnership underscores a key insight among leading manufacturers: consistent quality in critical components is foundational to uninterrupted production.

Precision Engineering for Standardized PV Production

The client's validation process was conducted under normal production conditions, reflecting real-world application. Our belts are engineered to excel within the precise and stable parameters of modern PV cell manufacturing, where furnace temperatures and wafer loads are carefully controlled and consistent. The high performance of our belts stems from their optimized standard design:

Standardized Materials & Weave:

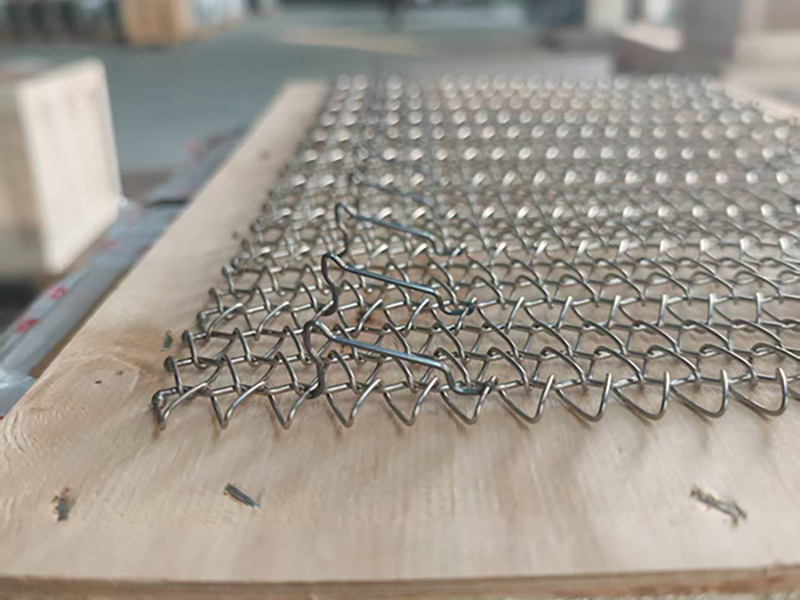

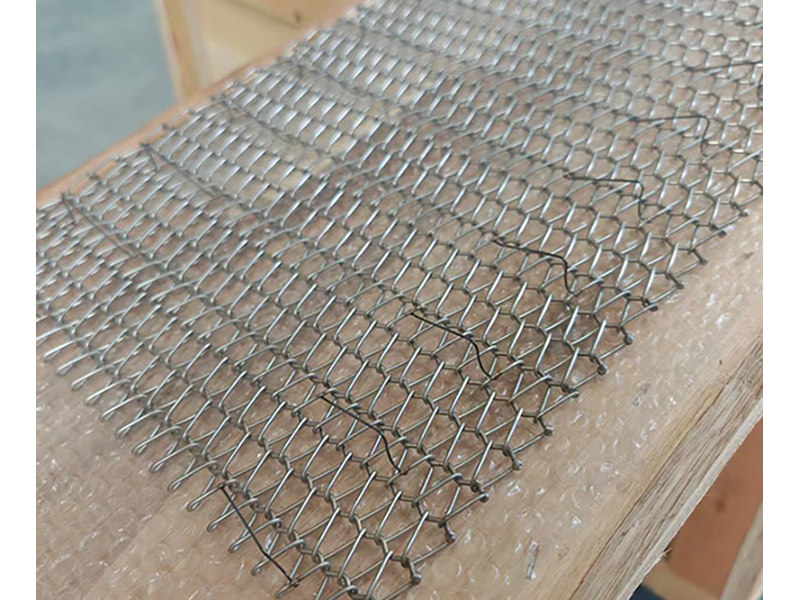

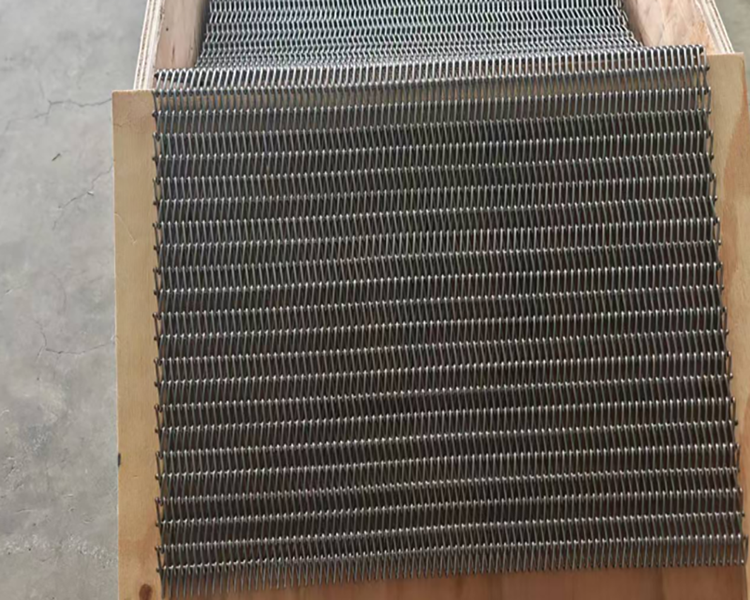

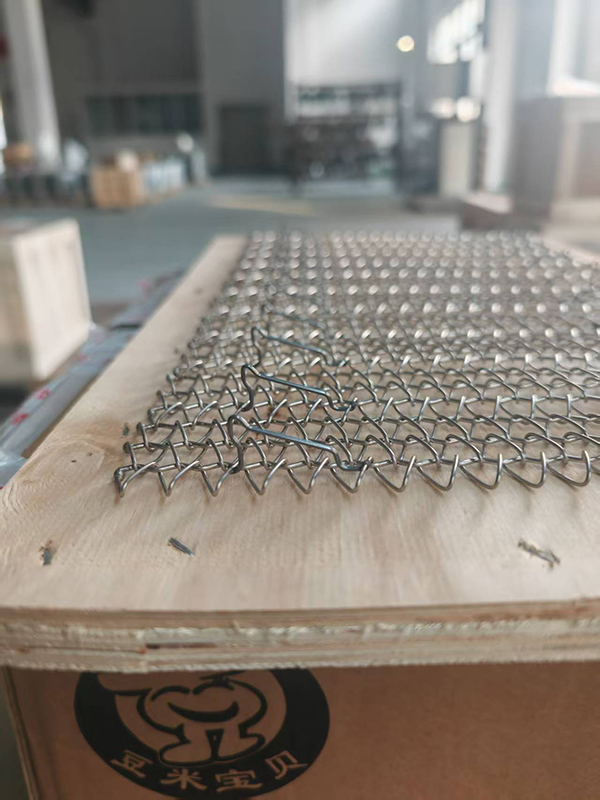

The sintering and LID furnace belts are crafted from Cr20Ni80 alloy, renowned for its superior high-temperature oxidation resistance, perfectly matching the stable yet demanding atmosphere inside these furnaces. The dryer oven belt utilizes AISI 316L stainless steel, offering an ideal balance of corrosion resistance and cost-effectiveness for lower-temperature drying processes. All belts feature a balanced weave structure, which provides excellent stability and minimizes stretching during operation.

Consistent Dimensional Specifications:

Adhering to industry standards, the spiral and cross wire diameters are maintained at consistent specifications to ensure compatibility and reliable performance across different production lines:

Sintering/LID Belts: Spiral wire diameter: 1.2mm; Cross wire diameter: 1.6mm.

Dryer Oven Belt: Spiral wire diameter: 1.6mm; Cross wire diameter: 1.8mm.

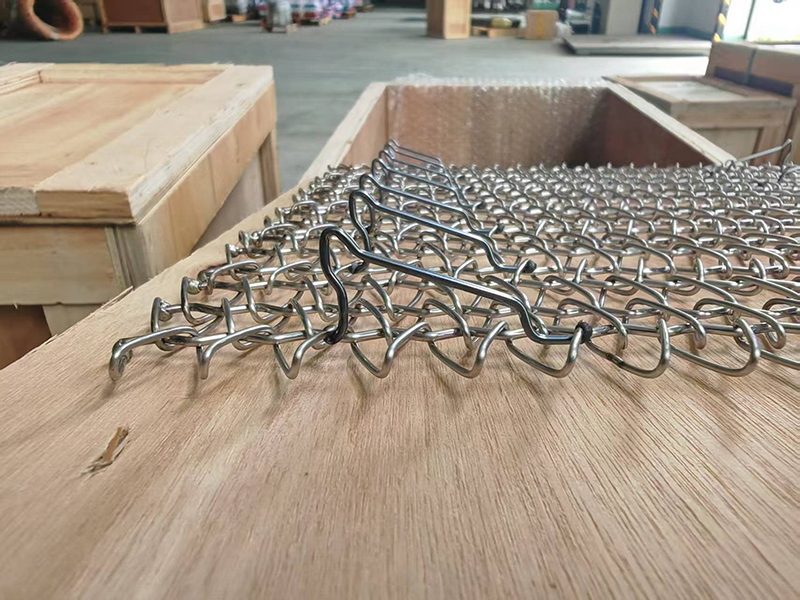

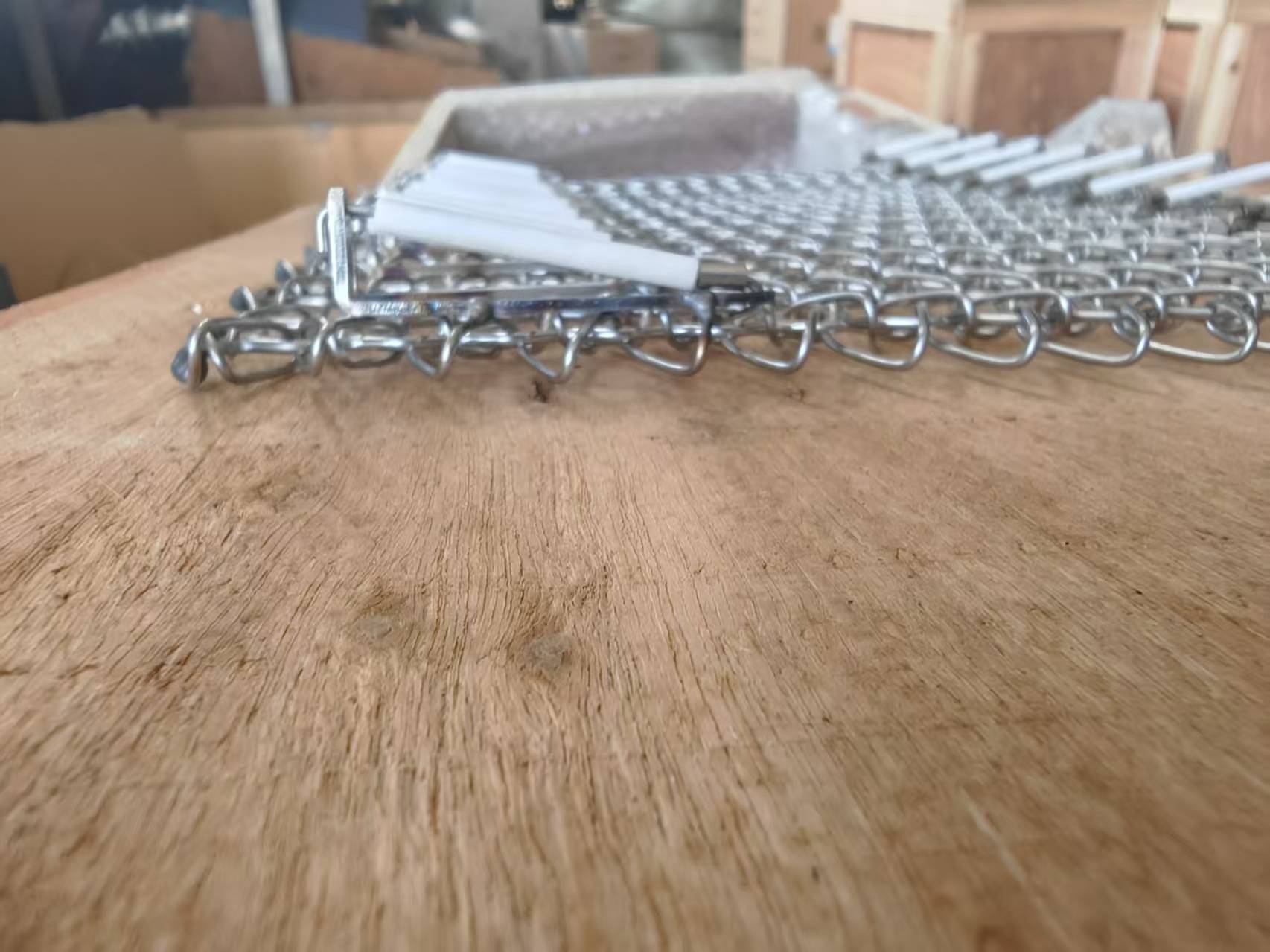

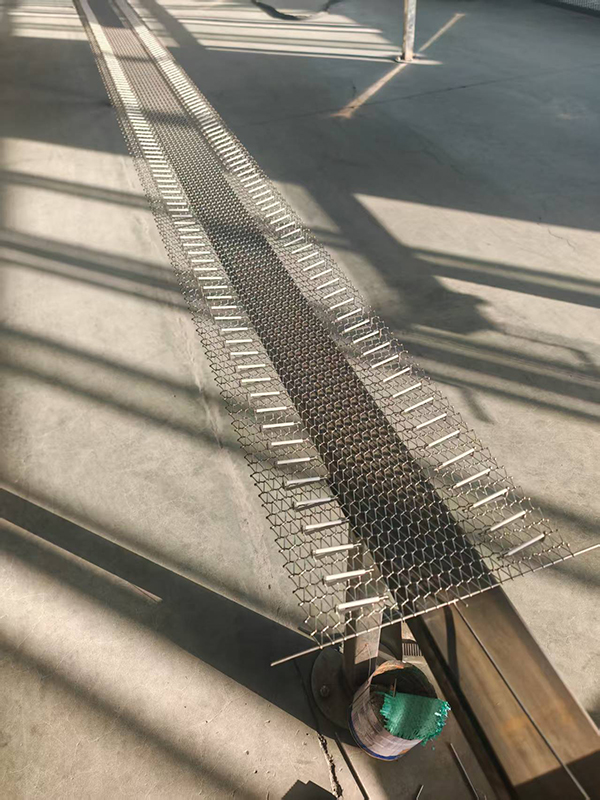

Customized Standoff Configuration:

The primary customization lies in the standoffs. The sintering and LID furnace belts feature standoffs with a black titanium coating, enhancing wear resistance. For the dryer oven belt, we applied a ceramic coating to the standoffs, providing optimal abrasion resistance in its specific operating environment. The layout and pitch of these standoffs are tailored to the client's specific fixture requirements, ensuring perfect wafer placement and stability.

Why Standardization with Customizable Components Wins Trust

This approach ensures every mesh belt delivers reliable performance under the specific thermal and mechanical loads of PV production. The client's confidence stems from our ability to provide a product that works seamlessly with their existing parameters, eliminating the need for process adjustments and guaranteeing product consistency. The balanced weave design is particularly crucial in PV manufacturing, as it maintains its shape and dimensional accuracy under continuous thermal cycling, directly contributing to prolonged service life and reduced downtime.

A Partnership Built on Reliability and Service

The client emphasized that beyond the product's quality, our responsive communication and reliable service were decisive factors. This partnership highlights that in a high-stakes industry like PV manufacturing, trust is built not just on the product's specifications but also on the supplier's ability to understand and integrate seamlessly into the client's operations. Our extensive experience within the PV sector allows us to speak the same language as our clients, anticipating needs and delivering solutions that simply work.

Applications Beyond Solar

While the parameters described are optimized for the PV industry, the core technology of our high-temperature Conveyor Mesh Belts finds applications in other fields requiring thermal processing, such as glass annealing and powder metallurgy, where consistent quality and durability are equally critical.

Invitation for Collaboration

We are committed to supporting the global expansion of PV manufacturing with our reliable, high-performance conveyor solutions. We invite OEMs and manufacturers worldwide to experience the difference that our standardized yet precisely adaptable Furnace Mesh Belt can make. For technical data sheets or to discuss your specific requirements, please contact us atjerry@meshbelt.cn or Cell & WhatsApp +86 187 6231 1618.