HUADA MESH BELT Supplies Custom AISI314 High-Temperature Wire Mesh Belts to Leading Japanese Powder Metallurgy Manufacturer

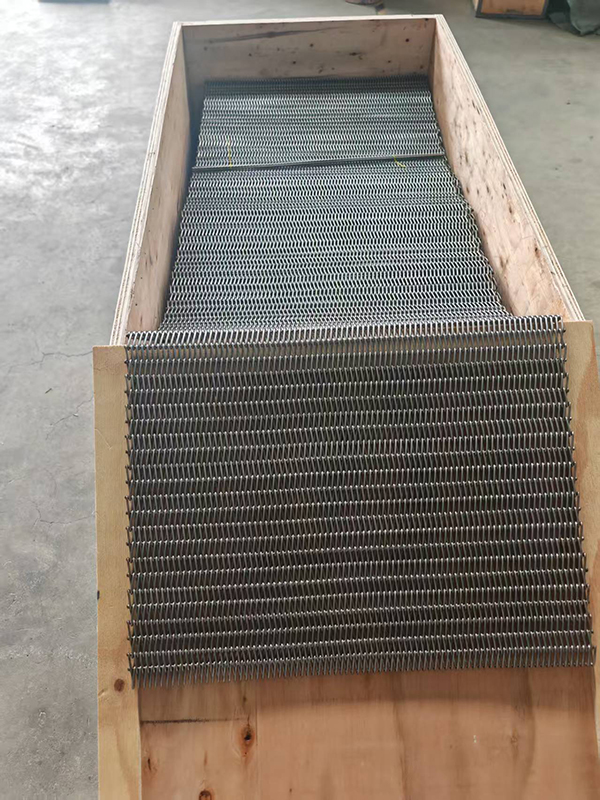

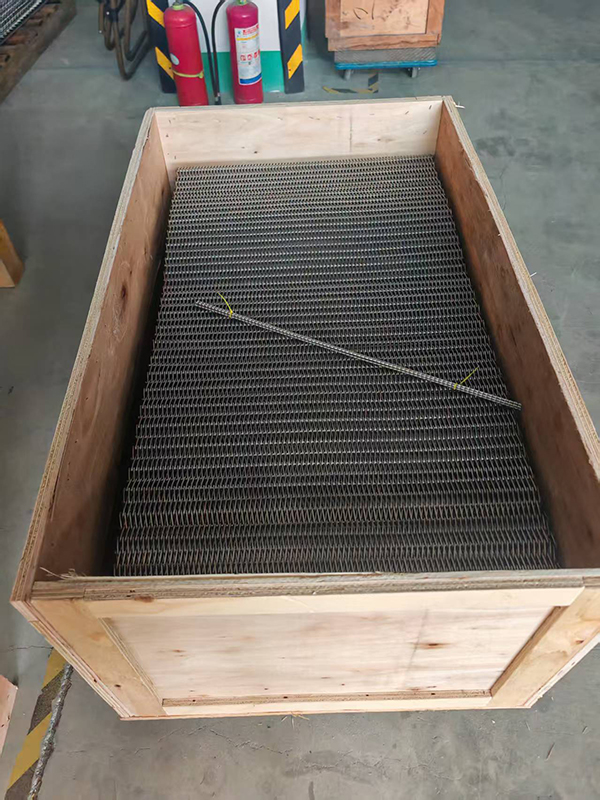

Yangzhou, China – Aug 28th – HUADA MESH BELT, a pioneer in high-temperature wire mesh belt manufacturing with over 30 years of expertise in the powder metallurgy (PM) sector, has secured its new international contract with a top-tier Japanese PM enterprise. The shipment of precision-engineered AISI314 stainless Steel Wire Mesh belts—customized to exact specifications—validates the company’s technical leadership and commitment to delivering solutions for extreme industrial environments.

Precision Engineering for Demanding Sintering Applications

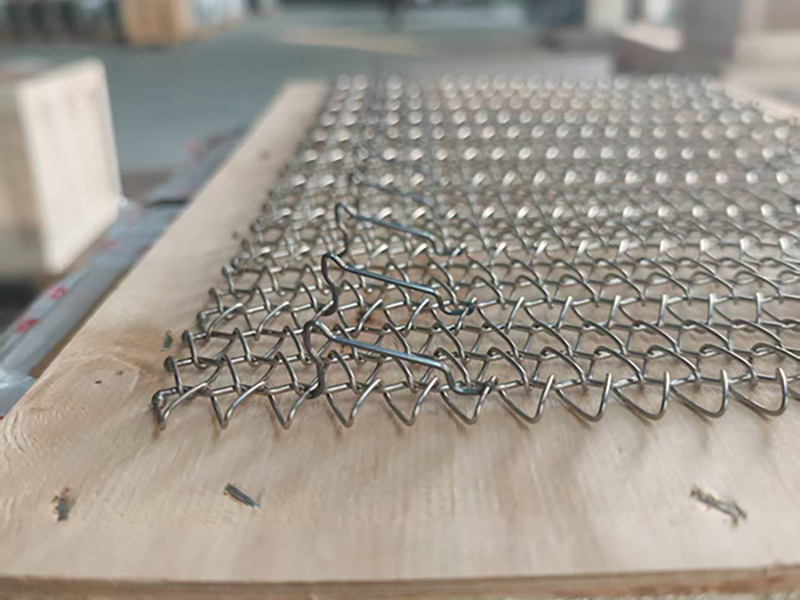

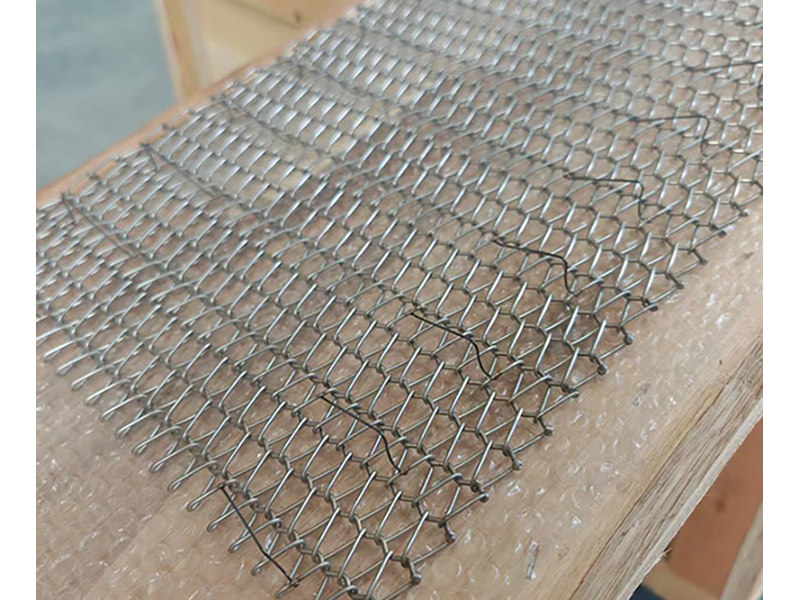

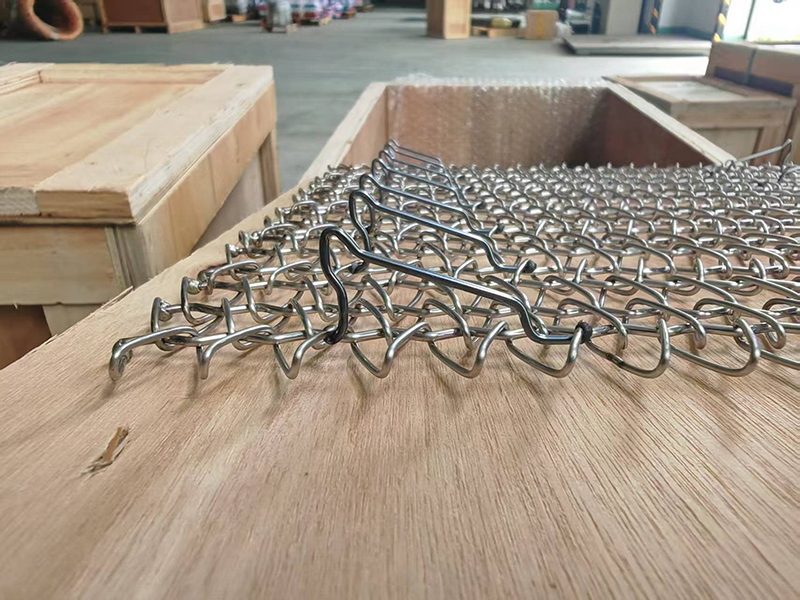

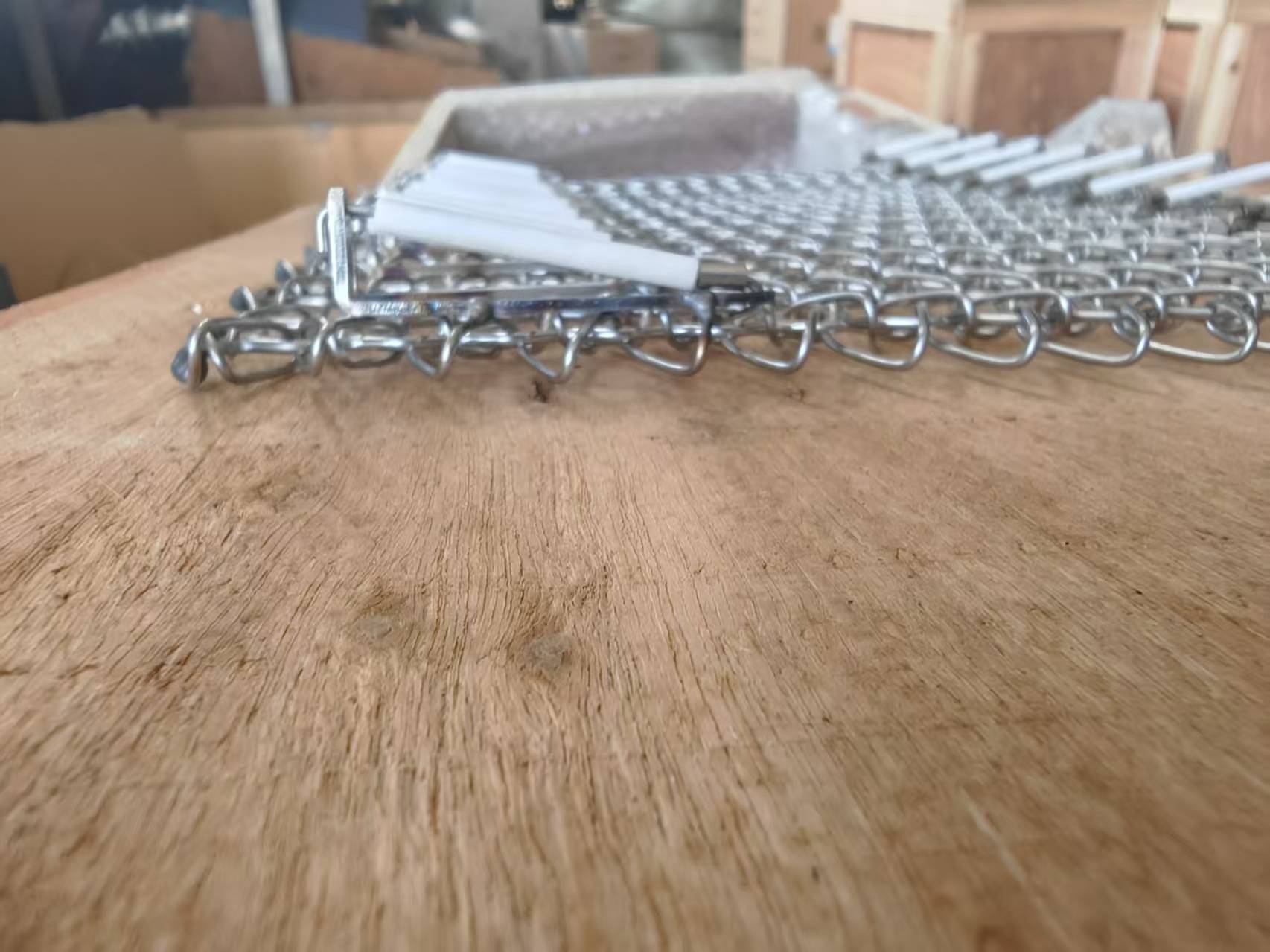

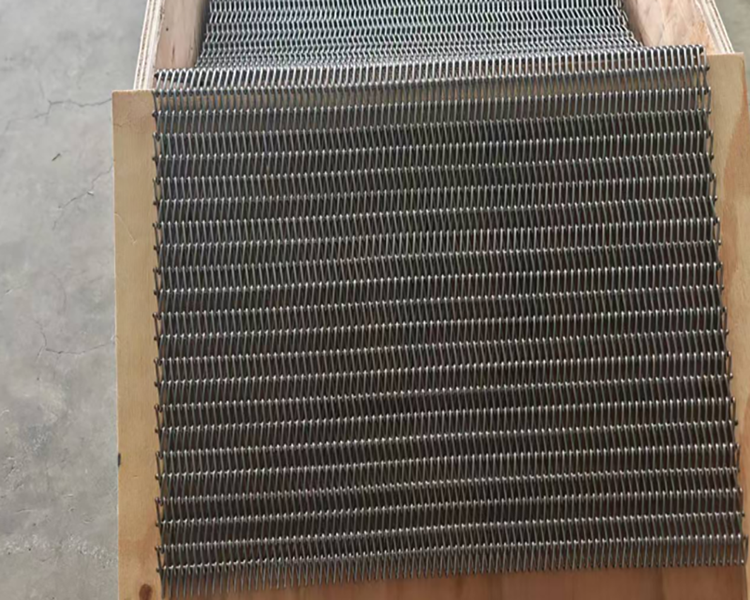

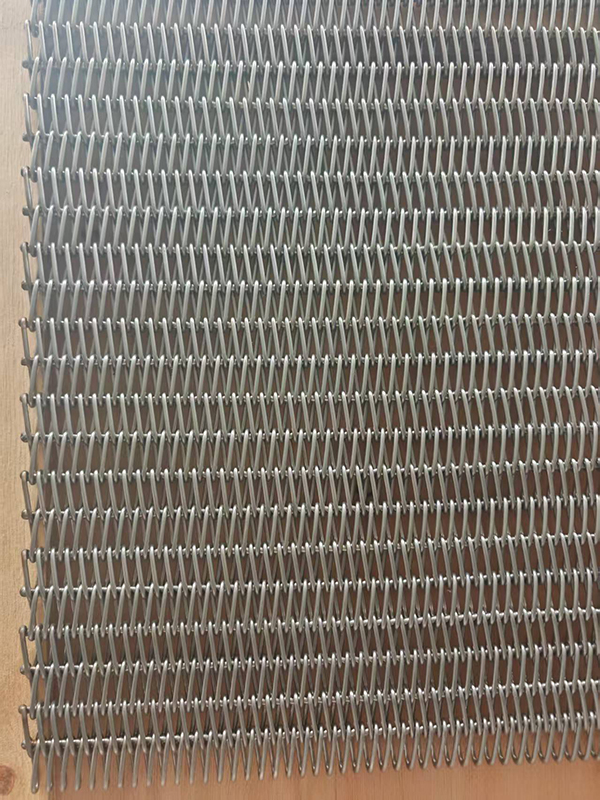

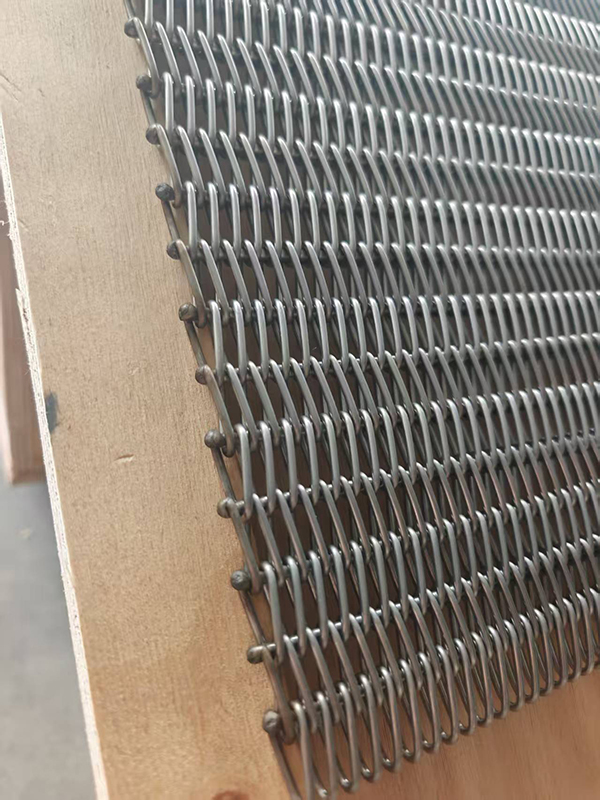

The AISI314 wire mesh belts supplied to the Japanese client feature critical dimensions optimized for high-performance sintering:

- Wire Diameter: 2.68mm spiral wire + 3.77mm cross wire, Reinforced edges and welded joints prevent deformation under loads exceeding 450 kg/m².

- Pitch Configuration: 7.26mm spiral pitch and 20.33mm cross pitch ensure uniform airflow and consistent product spacing.

- Temperature Resistance: Rated for continuous operation up to 1,150°C, ideal for sintering advanced ceramics and nickel-based super

Heavy-Duty Construction: “This collaboration underscores our ability to meet stringent Japanese quality standards,” says Mr. Cao, Technical Director at HUADA MESH BELT. “The client’s decision to transition from prototypes to full-scale production reflects their confidence in our high-temperature mesh belt solutions.”

From Prototypes to Production: A Testament to Excellence

The Japanese manufacturer initially commissioned two prototype batches to validate compatibility with their proprietary sintering furnaces. Key outcomes included:

- Zero Defect Compliance: Seamless integration with Mitsubishi Electric sintering systems, achieving ±03mmdimensional consistency over 5,000+ cycles.

- Energy Efficiency: Reduced thermal gradient by 15%, lowering operational costs by ¥1.8M annually.

- Sustainability: 100% recyclability of AISI314 material aligns with Japan’s Circular Economy 2030 goals.

This success solidified our position as a trusted partner, culminating in long-term supply agreement for 3000+ meters of Wire Mesh Conveyor belts annually.

Why Global Manufacturers Choose HUADA MESH BELT

- Proven Expertise:

Over 30 years of experience supplying wire conveyor belts for PM industry applications, including hardfacing alloys and zirconia ceramics.

Advanced R&D capabilities, including finite element analysis (FEA) for stress optimization.

- Customization Excellence:

Adjustable spiral pitches and ceramic-coated options to prevent coating adhesion—a common challenge in PM sintering.

- Global Compliance:

ISO 9001:2015 and IATF 16949 certifications ensure traceability from raw material sourcing (partnering with Bao steel) to final delivery.

Join the Revolution in Powder Metallurgy

HUADA MESH BELT invites global manufacturers to experience precision-engineered high-temperature mesh belts that redefine industrial efficiency. For OEM collaborations or bulk orders, contact:

📧 jerry@meshbelt.cn| 📞 +86 187 6231 1618

🌐 site_5692daef-da17-420f-94c5-497c98eb8172

About HUADA MESH BELT

Since 1992, HUADA MESH BELT has specialized in thermal processing solutions for powder metallurgy, aerospace, and renewable energy sectors. Our innovations have powered 2.1M+ MT of advanced materials globally.