Premium 304/316L Stainless Steel Belts for Spiral Freezers & Beer Pasteurizing Lines

Meta Description:Jiangsu Huada Metal Mesh Belt Co., Ltd provides food-grade 304/316L stainless Steel Conveyor Belts for spiral freezers (IQF food freezing) and corrosion-resistant wire ring belts for beer bottle sanitization. ISO-certified solutions for hygienic processing.

High-Performance Conveyor Solutions for Food Freezing & Beverage Sanitization

Jiangsu Huada Metal Mesh Belt Co.,Ltd, a trusted manufacturer of industrial Metal Conveyor belts, introduces two specialized product lines engineered for critical food and beverage applications: spiral freezer belts for rapid freezing and wire ring belts for beer bottle pasteurization. Built with 304/316L stainless steel, these belts combine hygiene, durability, and thermal efficiency.

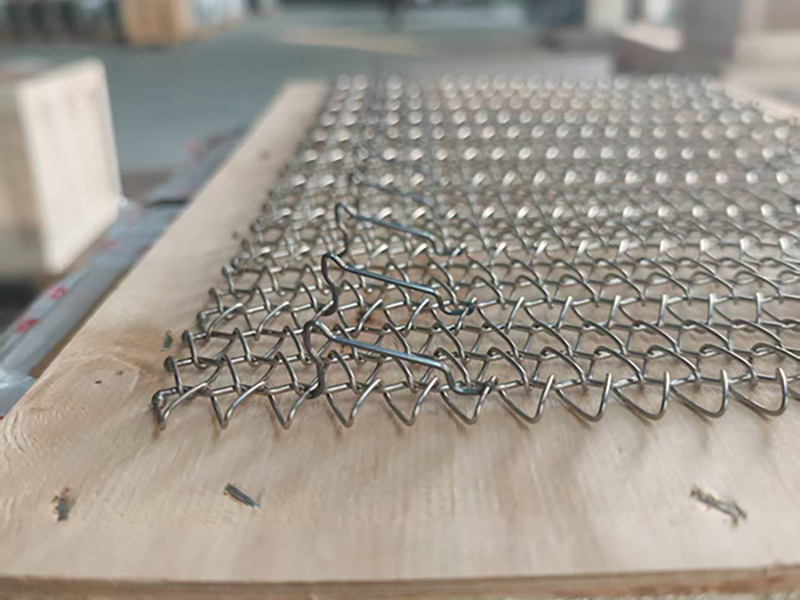

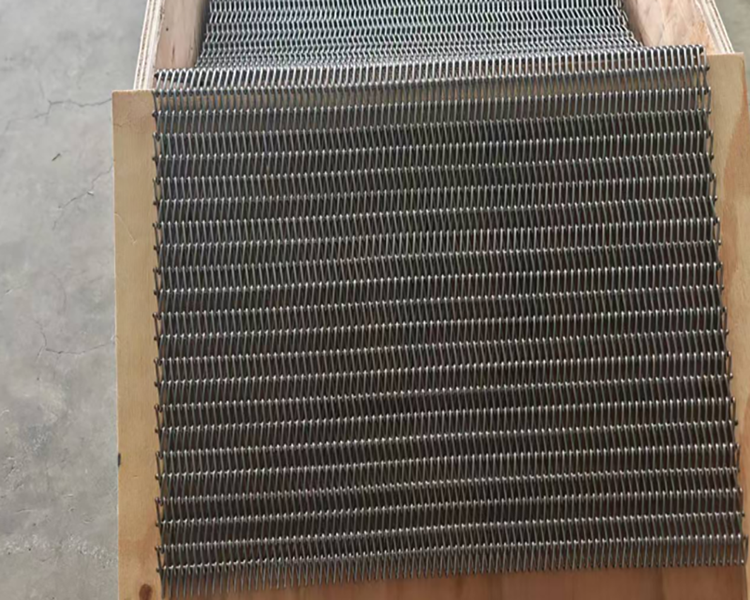

1. Spiral Freezer Conveyor Belts for IQF Food Processing

Ideal for Individual Quick Freezing (IQF) of seafood, vegetables, and ready-to-eat meals, our spiral freezer belts withstand temperatures as low as -40°C while maintaining flexibility.

Key Advantages:

• Material: 304/316L stainless steel for rust resistance in high-moisture environments.

• Open Mesh Design: Accelerates airflow to achieve 90% freezing efficiency faster than solid belts.

• Anti-Stick Surface: Prevents frozen product adhesion, reducing downtime for ice removal.

• FDA & EU Compliance: Meets strict food safety standards for direct contact.

Industries Served: Frozen seafood processors, vegetable freezing plants, and prepared meal manufacturers.

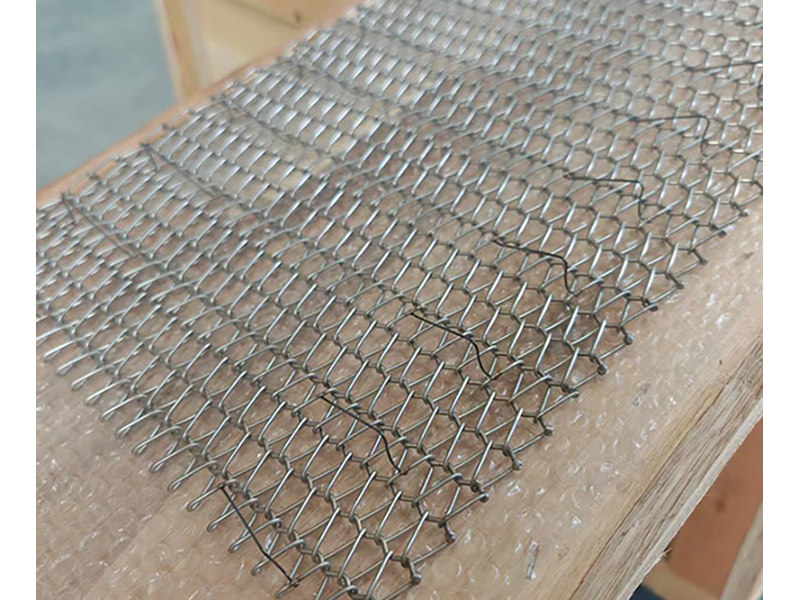

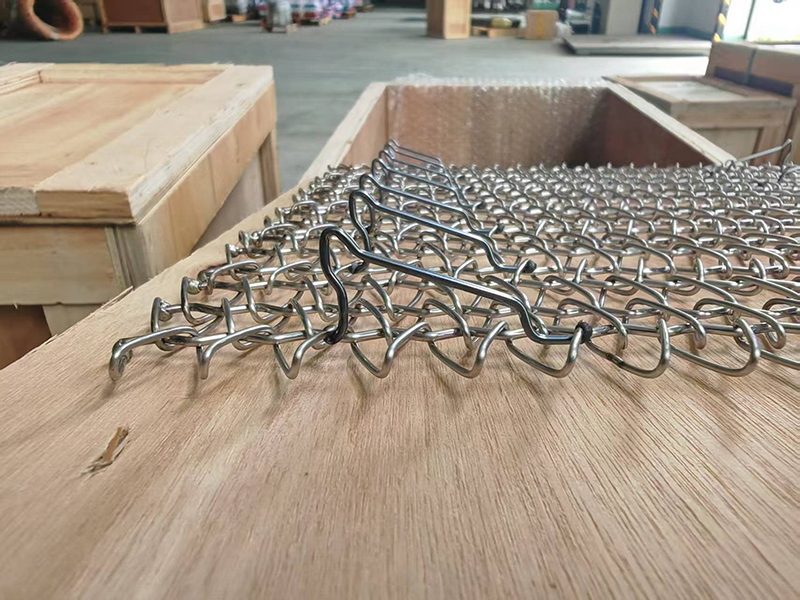

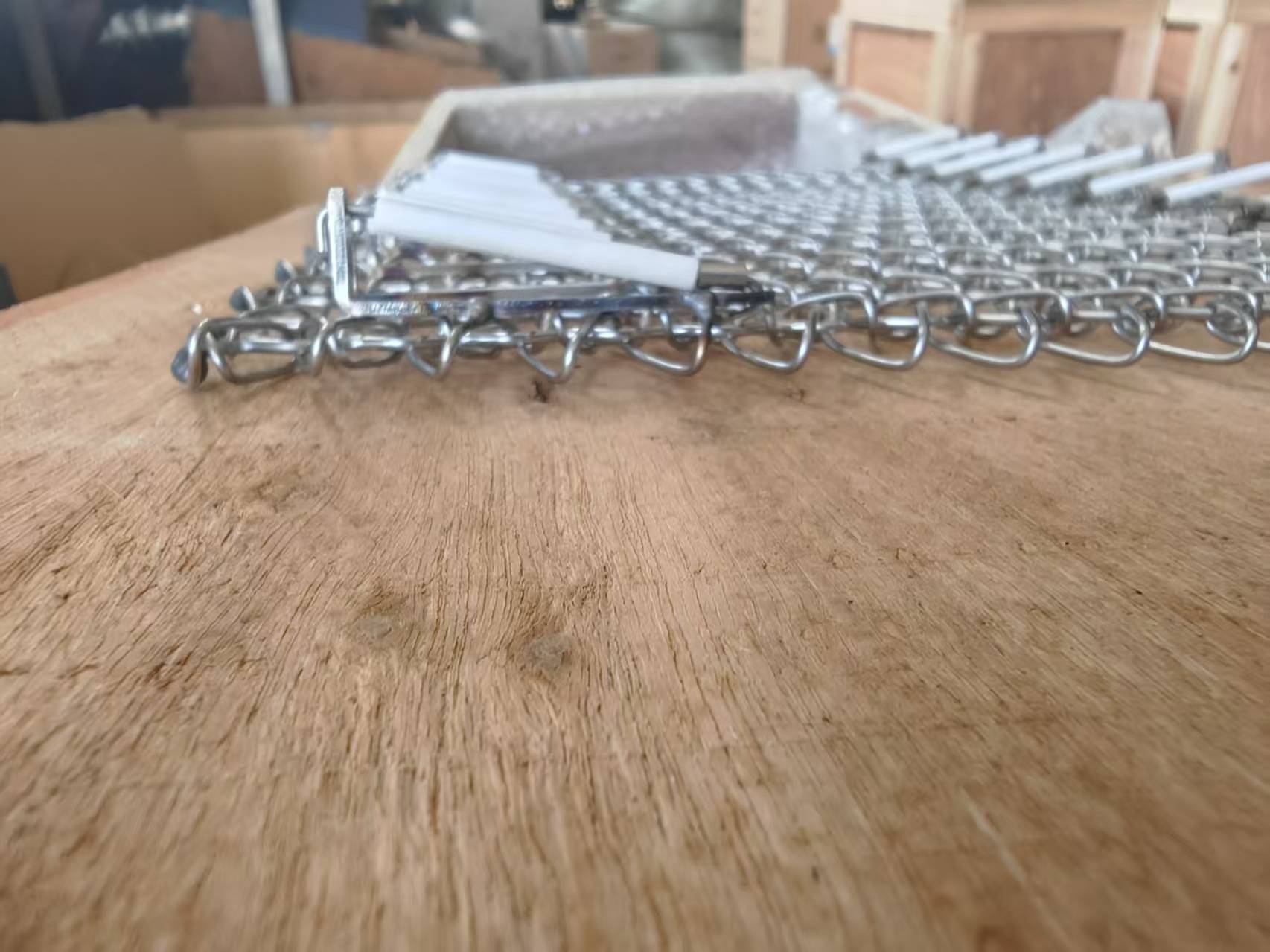

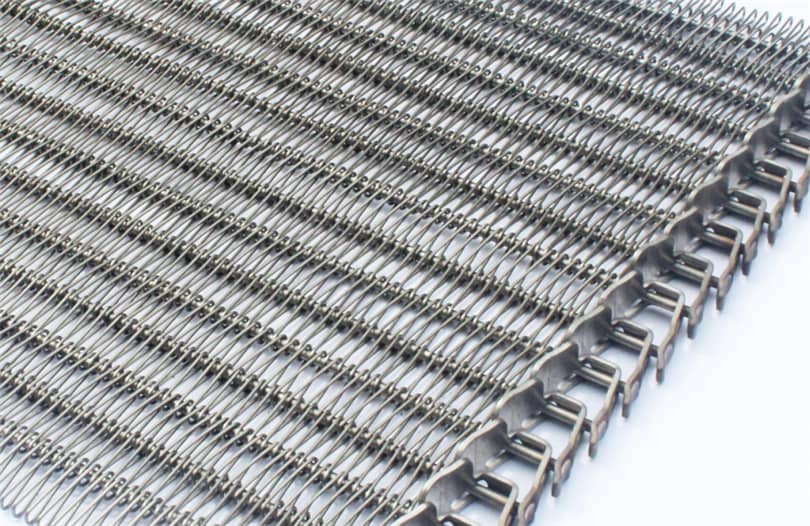

2. Wire Ring Belts for Beer Bottle Pasteurizing Lines

Engineered for brewery sanitization systems, our interlocked wire ring belts endure high-temperature steam (85°C+) and caustic cleaning chemicals in bottle washing/pasteurizing tunnels.

Critical Features:

• Corrosion Resistance: 316L stainless steel construction withstands acidic/alkaline detergents.

• Smooth Surface: Prevents bottle jamming and label damage during high-speed conveying.

• Easy Maintenance: Modular design allows quick replacement of damaged wire links.

• Hygienic Structure: No crevices for bacterial growth, critical for beverage CIP (Clean-in-Place) protocols.

Trusted By: Craft breweries, industrial beer producers, and bottling line integrators.

Why Huada Mesh Belt?

Material Expertise: Select 304 or 316L steel based on your temperature/chemical exposure needs.

Custom Engineering: Belt widths from 200mm to 3m, tailored mesh patterns, and edge reinforcements.

Certifications: ISO 9001, HACCP, and material traceability reports provided.

Call to Action:

Upgrade your food freezing or beverage sanitization line with precision-engineered belts! Contact us at +86 187 6231 1618 or jerry@meshbelt.cn for a free technical consultation or request belt sample testing.