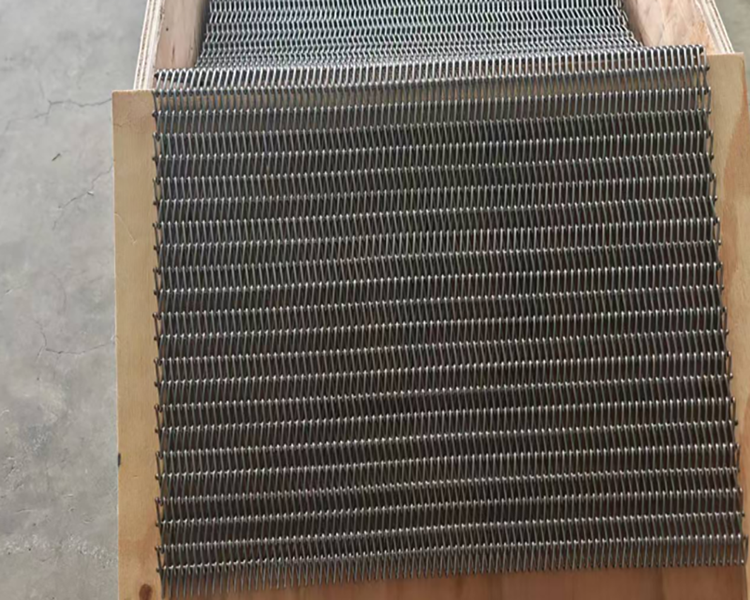

HUADA Supplies SUS 316L Flat Flex Belts to Singapore's Leading Food Processor

Yangzhou, China – July 18, 2025 – HUADA MESH BELT, a pioneer in industrial thermal processing solutions with over three decades of expertise, today announced the successful shipment of custom SUS 316L flat flex belts to a top-tier food manufacturing enterprise in Singapore. This marks the latest milestone in a decade-long partnership, underscoring HUADA’s commitment to delivering precision-engineered flat flex Conveyor Belting for hygiene-critical applications.

Decade-Long Partnership Fueled by Reliability

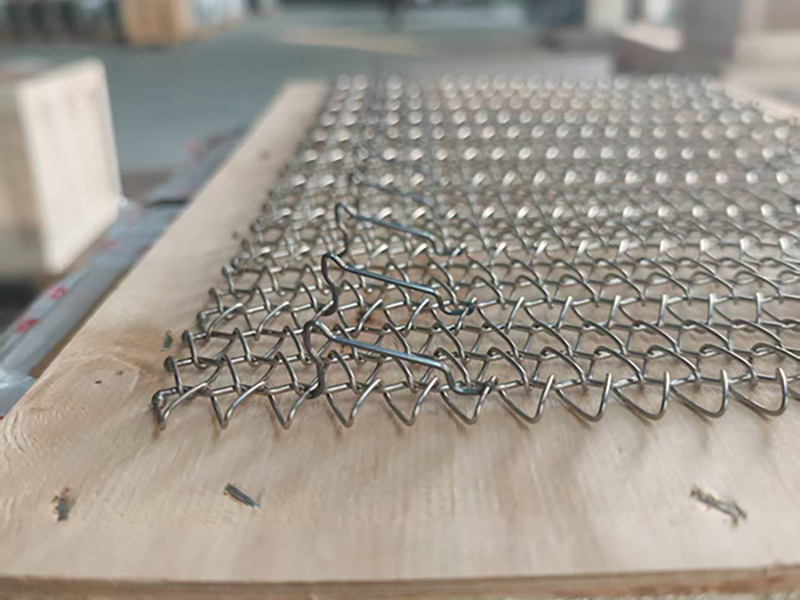

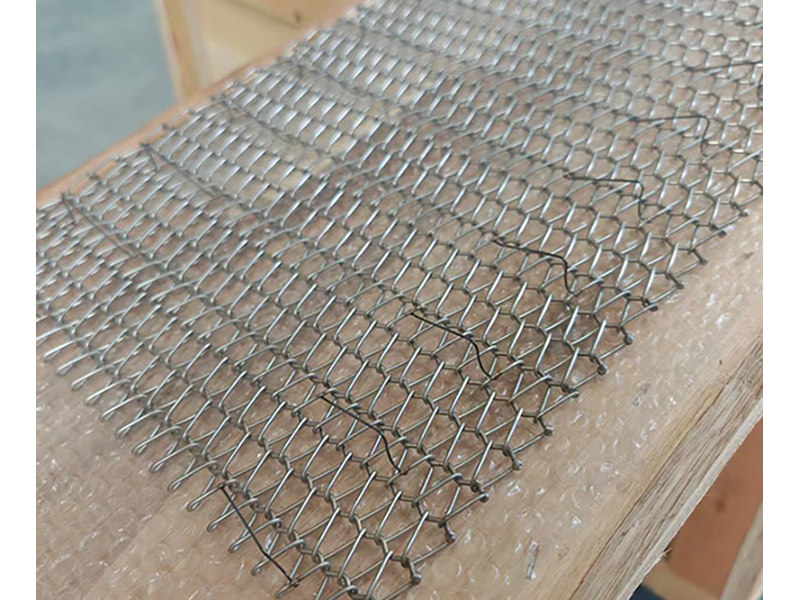

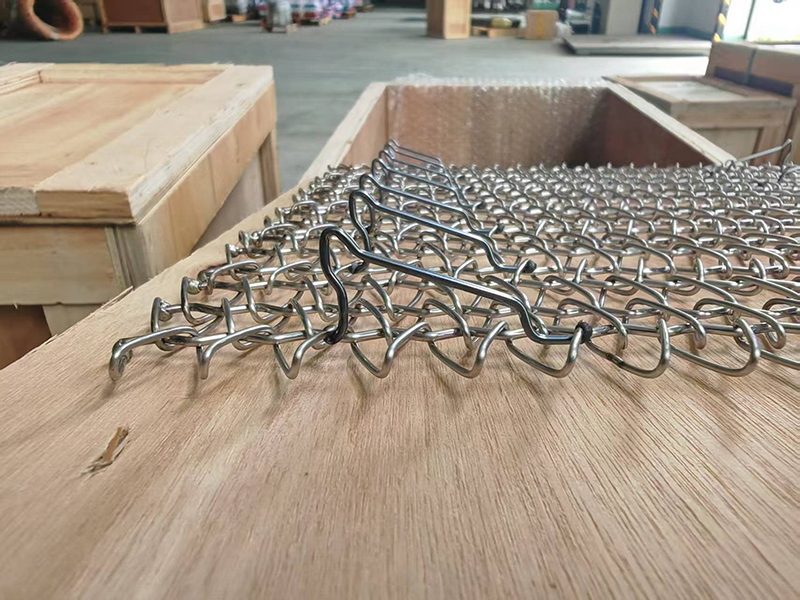

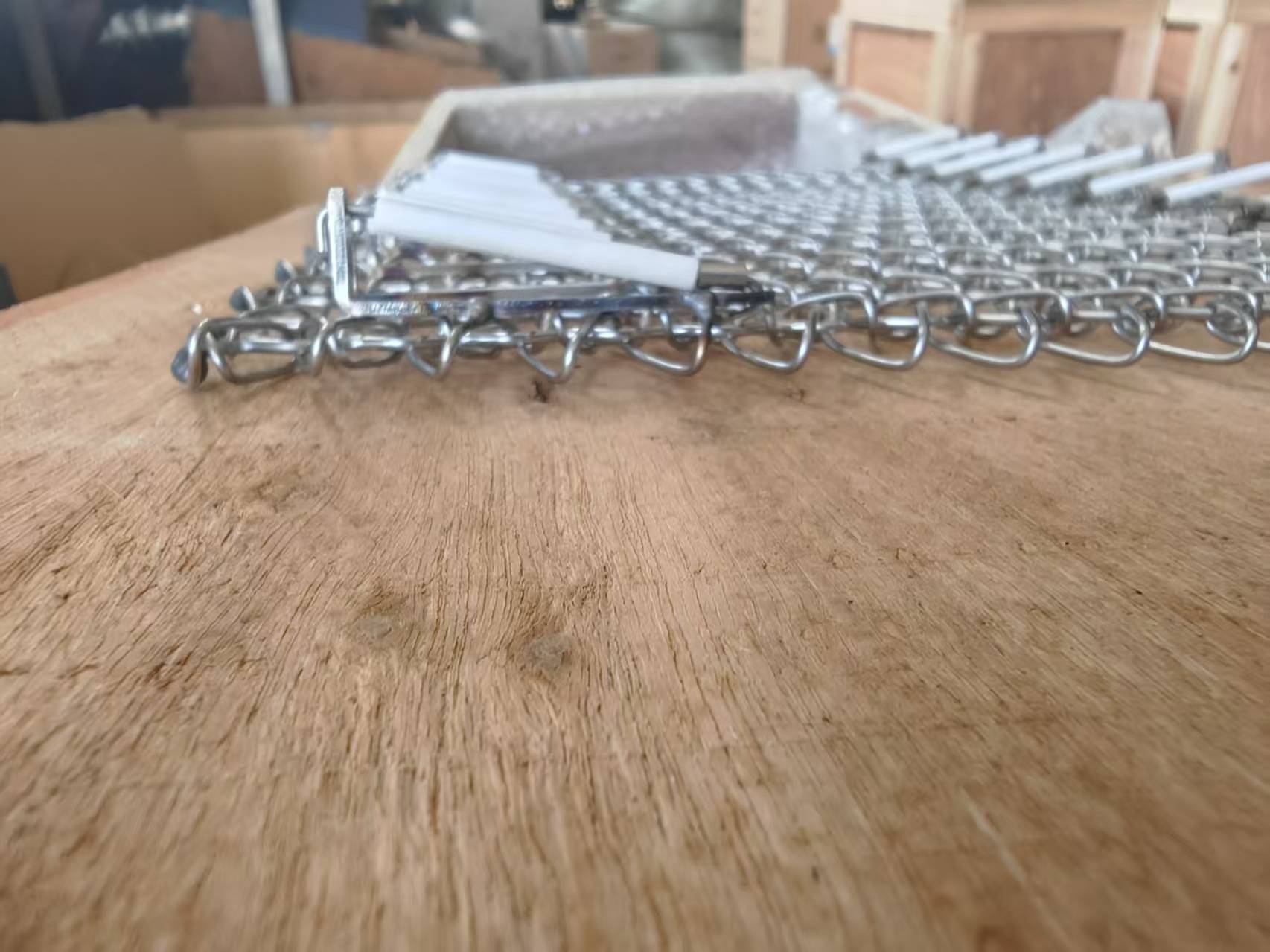

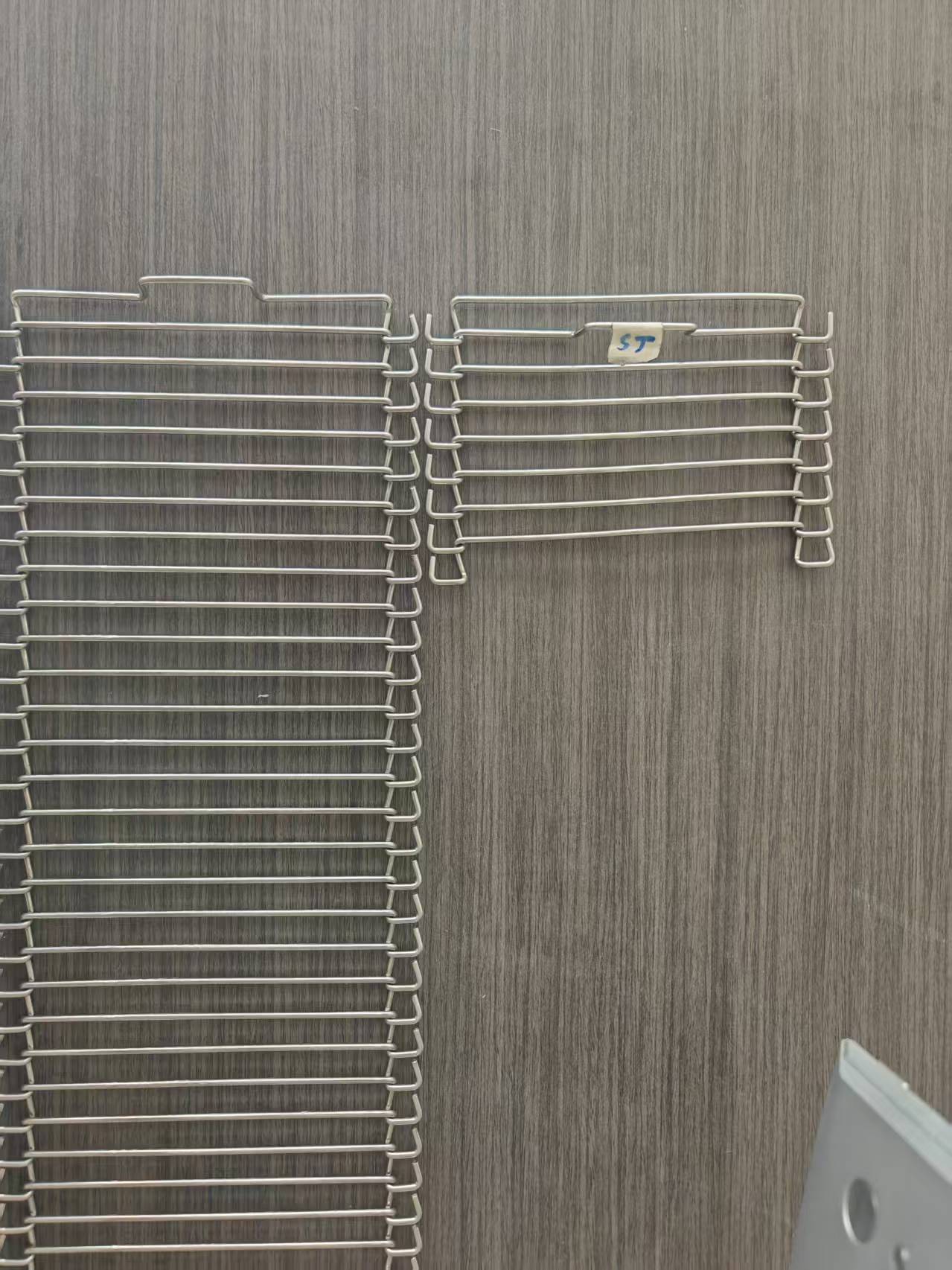

HUADA’s SUS 316L flat flex belt—designed for high-temperature, corrosion-resistant environments—has been a cornerstone of this Singaporean client’s production line since 2016. The latest order, comprising belts with 2.35mm wire diameter, 12.5mm wire pitch, and 154mm overall width, reflects the client’s confidence in HUADA’s ability to meet stringent food safety standards.

“We've consistently chosen HUADA for their ability to combine durability with precision,” says Ms. Anita Mok, Head of Operations at the Singaporean facility. “Their SUS 316L Mesh Conveyor belts have withstood 10+ years of 24/7 operation in our sizzling kitchens, maintaining hygiene and efficiency.”

Technical Excellence in Food-Grade Belting

- Material: SUS 316L stainless steel (16–18% chromium, 10–14% nickel) ensures resistance to chlorides and acidic residues common in food production.

- Design: 12.5mm wire pitch optimizes airflow for uniform cooling during chocolate tempering, while the 2.35mm wire diameterminimizes product adhesion.

- Certifications: Compliant with FDA, BRCGS, and HACCP, with full traceability documentation.

Why HUADA Stands Out in Competitive Markets

- Customization Expertise: Adjust wire diameter (1–3mm), pitch (8–20mm), or surface coatings (e.g., PTFE) to match specific food applications.

- Global Logistics: Efficient shipping from Yangzhou to Singapore in 5-7 working days, with temperature-controlled storage options.

- Sustainability: 95% recyclable materials and energy-efficient manufacturing processes.

Client Success Story

The Singaporean enterprise initially chose HUADA for their flat flex conveyor belting in 2016 to replace outdated PVC belts prone to warping. Over the decade, HUADA has:

- Reduced maintenance costs by 40% through extended service intervals.

- Enabled a 15% increase in throughput via reduced belt deformation.

- Supported expansion into plant-based food lines with FDA-compliant belt upgrades.

Join Hundreds of Global Food Leaders

HUADA’s flat flex belts now power food production in 25+ countries. For inquiries about OEM customization or bulk orders, contact our team:

📧 jerry@meshbelt.cn | 📞 +86 187 6231 1618

🌐 site_5692daef-da17-420f-94c5-497c98eb8172