Immediate Repeat Order! Top Indian PV Manufacturer Expands Partnership for Advanced LID Furnace Mesh Belt

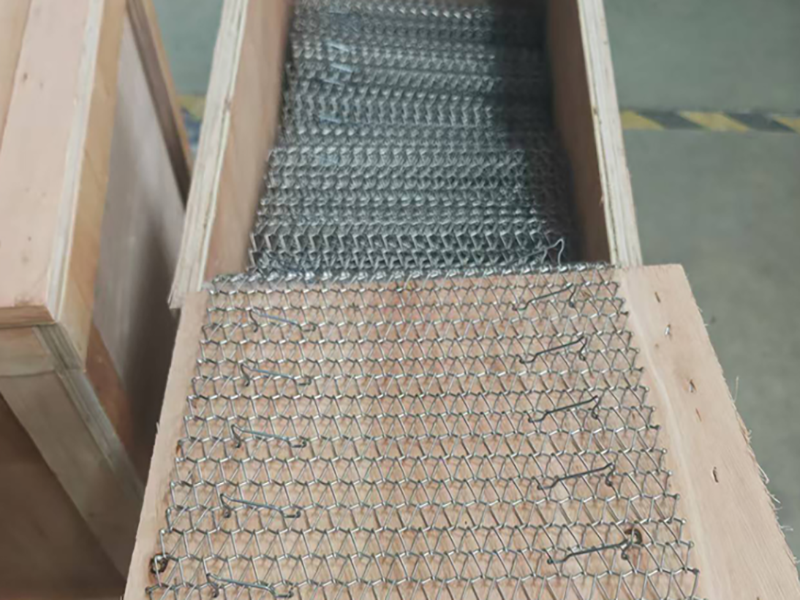

Yangzhou City, China – Sept 28th – Following a successful trial of high-temperature sintering and LID Furnace Mesh Belts, a leading Indian photovoltaic (PV) manufacturer has placed an urgent repeat order with HUDA MESH BELT for custom LID mesh belts to upgrade multiple production lines. This rapid reorder underscores the critical role of precision-engineered conveyor belts for solar cell sintering, LID and drying processes in India’s booming solar industry, driven by the exceptional performance of ceramic-enhanced standoffs and high-temperature alloy materials in demanding PV manufacturing environments.

Why Indian Solar Giants Choose Custom LID Mesh Belt

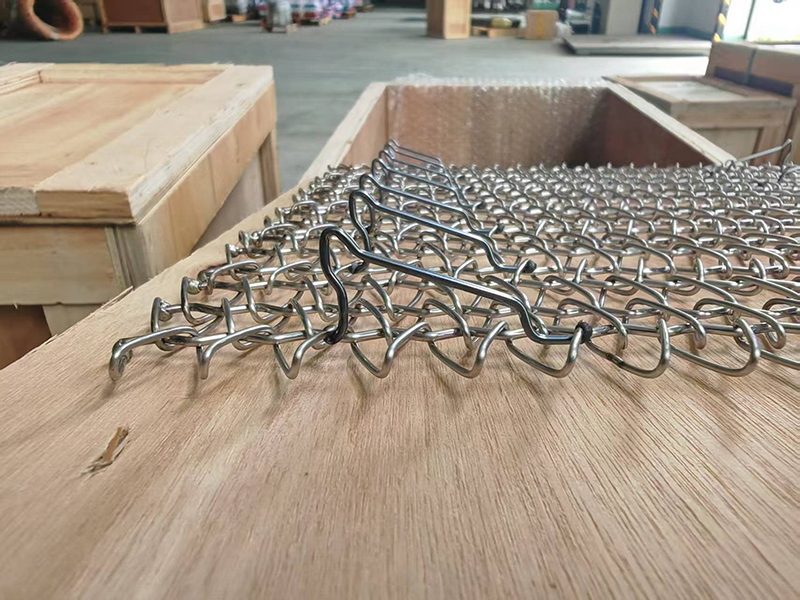

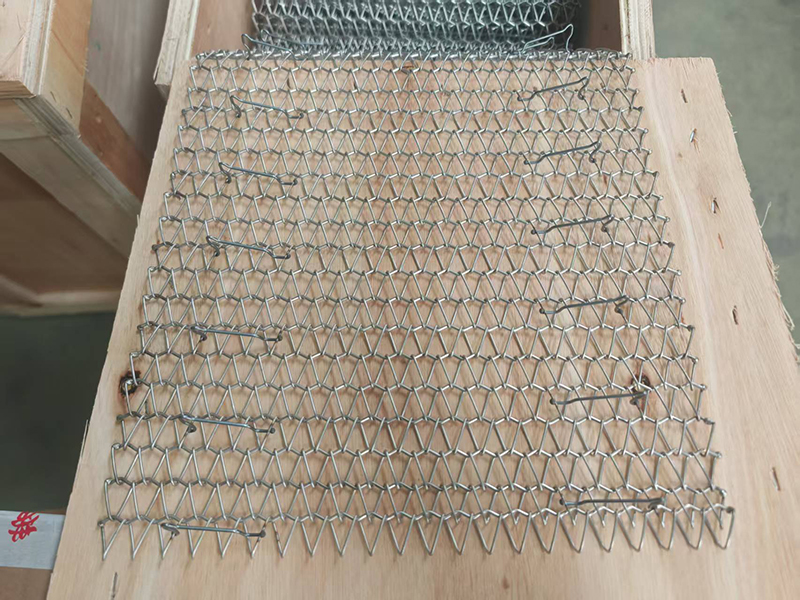

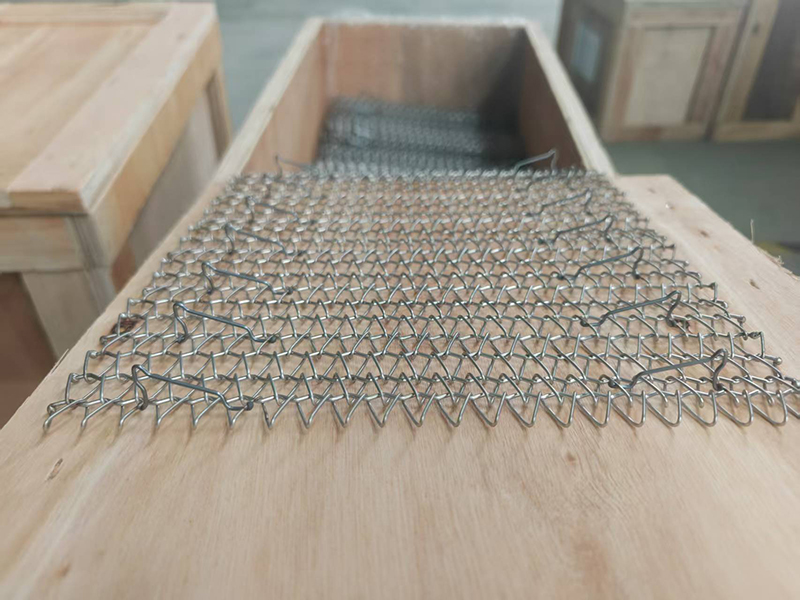

The LID (Light-Induced Degradation) furnace mesh belts supplied by HUADA MESH BELT are engineered to address unique challenges in solar cell production:

- Material Superiority:Crafted from high-temperature nickel-chromium alloys (e.g., Cr20Ni80), these belts withstand continuous operation at1,150°C+, significantly outperforming standard stainless steel (304/316) in oxidation resistance and thermal stability.

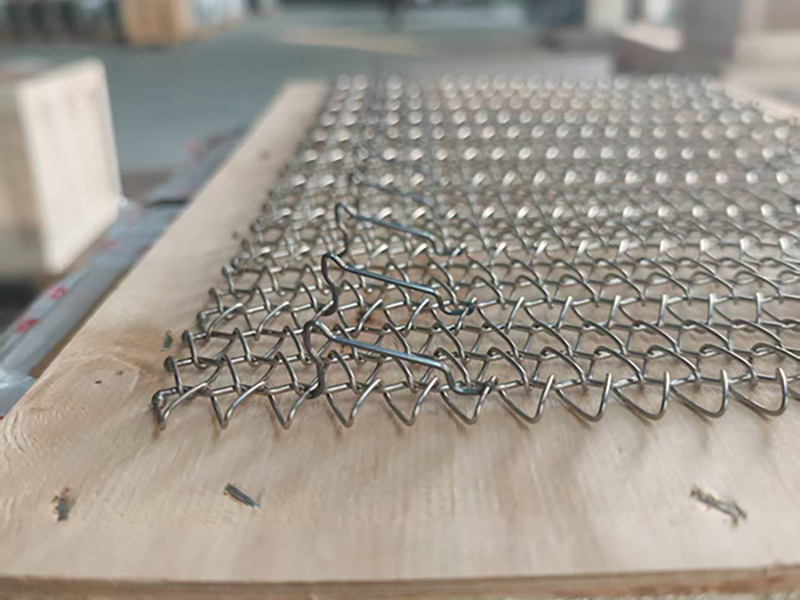

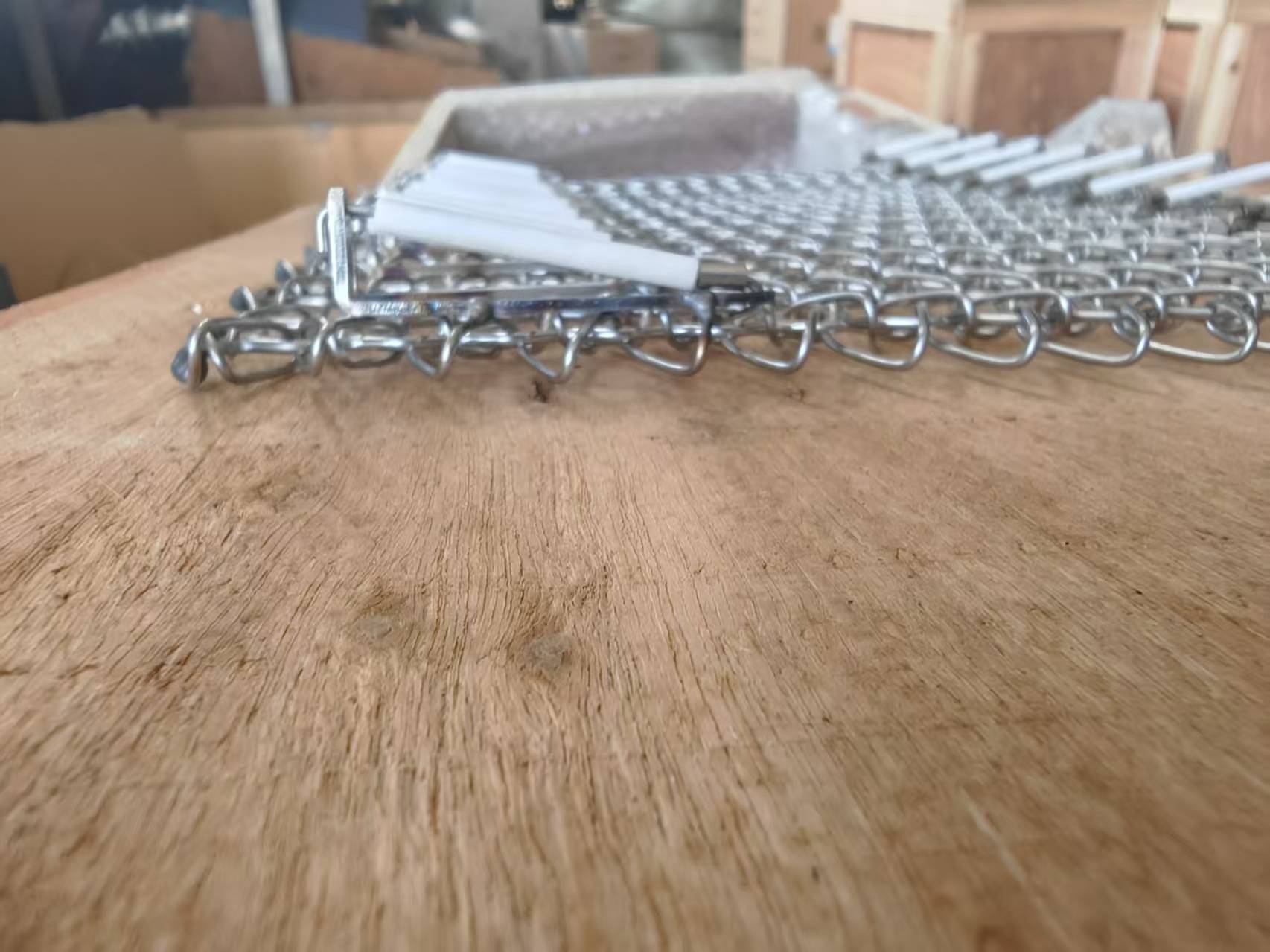

- Ceramic-ArmoredStandoffs: Custom-designed standoffs with ceramic sleeves (Mohs hardness 9) reduce abrasive wear by 90% compared to uncoated metal, critical for handling textured silicon wafers without contamination.

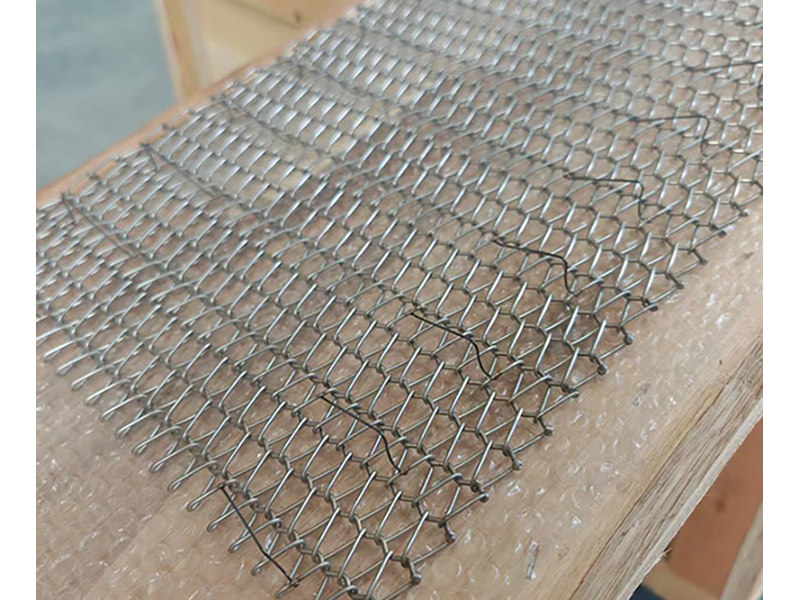

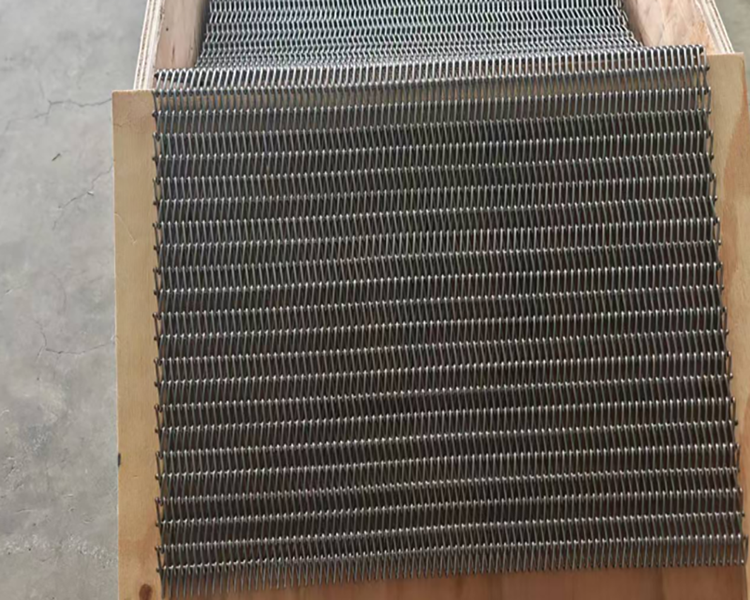

- Optimized Layout: Spiral and cross rod configurations (e.g., 36mm spiral wirepitch& 16mm cross wire pitch) ensure uniform heat distribution during LID treatment, minimizing cell efficiency losses.

“The ceramic-coated standoffs were a game-changer,” noted the client’s Production Head. “We saw zero particulate contamination during LID cycles, allowing us to extend belt replacement intervals from 6 to 12 months.”

Technical Breakdown: Engineering for Solar Cell Production

| Component | Specification | PV Application Benefit |

| Base Material | Cr20Ni80 alloy (Ni80%/Cr20%) | Resists sulfidation in LID atmospheres (N₂/H₂ mixes) |

| Standoff Design | Ceramic-sleeved, custom pitch | Prevents wafer slippage at conveyor speeds of 0.5–2 m/min |

| Thermal Resilience | 1,150°C continuous use | Maintains tensile strength during rapid quenching cycles |

| Mesh Structure | Balanced weave, 12.36–16mm openings | Enables 30% faster gas diffusion for uniform degradation mitigation |

The belts’ open mesh design allows precise control of process gases (e.g., H₂/N₂ mixtures) during LID treatment, a key factor in reducing light-induced efficiency losses in PERC and TOPCon cells.

From Trial to Trust: How Performance Drove Immediate Reorder

The Indian manufacturer initially tested belts for two critical processes:

- Sintering Furnace Belt:For metallization of cell contacts.

- LID Furnace Belt:For stabilizing cell efficiency under light exposure.

After 1,000+ hours of operation, the LID mesh belt demonstrated:

- Zero Wafer Breakage:Ceramic standoffs eliminated micro-scratches on 180μm thin wafers.

- Energy Savings:22% reduction in gas consumption due to optimized airflow.

- Yield Boost:8% absolute efficiency gain in final cell testing.

This success triggered an emergency order for 6 additional LID lines, with deployment scheduled within 45 days to meet rising demand for high-efficiency modules.

India’s Solar Expansion Fuels Demand for Specialized Conveyor Solutions

India aims to reach 100GW of solar capacity by 2030, spurring investments in advanced manufacturing. HUDA MESH BELT’s belts now support:

- Sintering Lines:For contact formation using silver pastes.

- LID Systems: Mitigating degradation in mono-PERC cells.

- Dryer Ovens: Removing moisture after texturing and coating.

Global Impact: Scaling Solar-Grade Conveyor Solutions

With installations in 15 countries, HUDA MESH BELT combines:

- R&D Customization:48-hour prototyping for unique furnace layouts.

- Material Science: Alloys validated for sulfur-rich atmospheres in Indian industrial zones.

- Certifications:ISO 9001:2015 compliance, with material traceability from mill to installation.

Join the Solar Manufacturing Revolution

HUADA MESH BELT invites PV manufacturers to experience precision-engineered mesh belts that redefine efficiency. For OEM collaborations or bulk orders:

📞 +86 187 6231 1618 | 📧 jerry@meshbelt.cn

🌐 site_5692daef-da17-420f-94c5-497c98eb8172