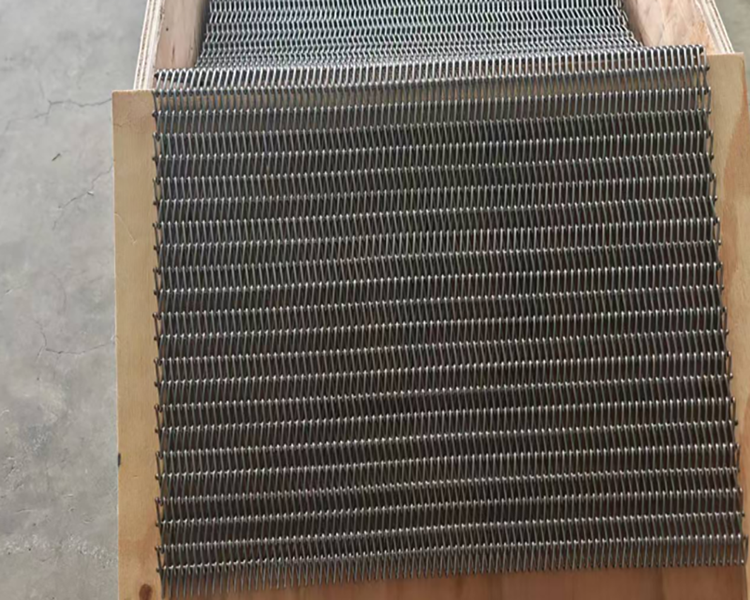

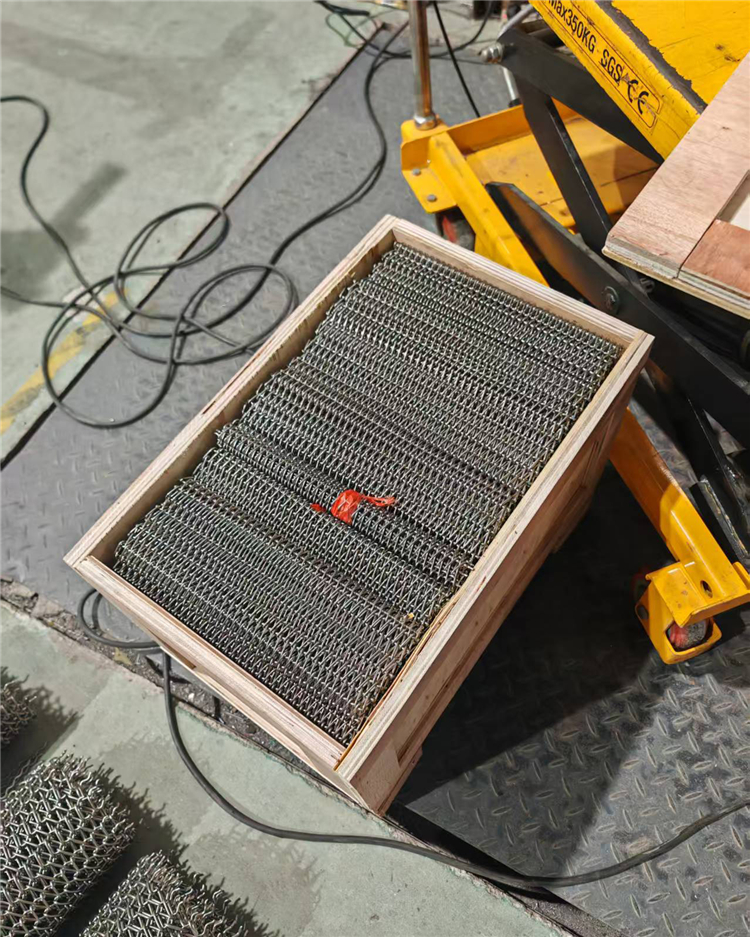

Vietnamese Manufacturer Selects Our 310S Alloy Furnace Conveyor Belt for High-Temperature Heat Treatment Line

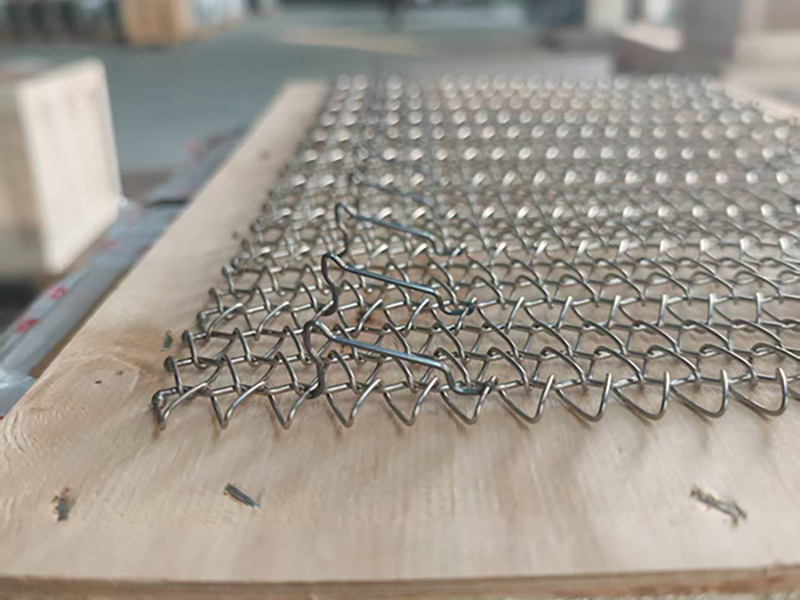

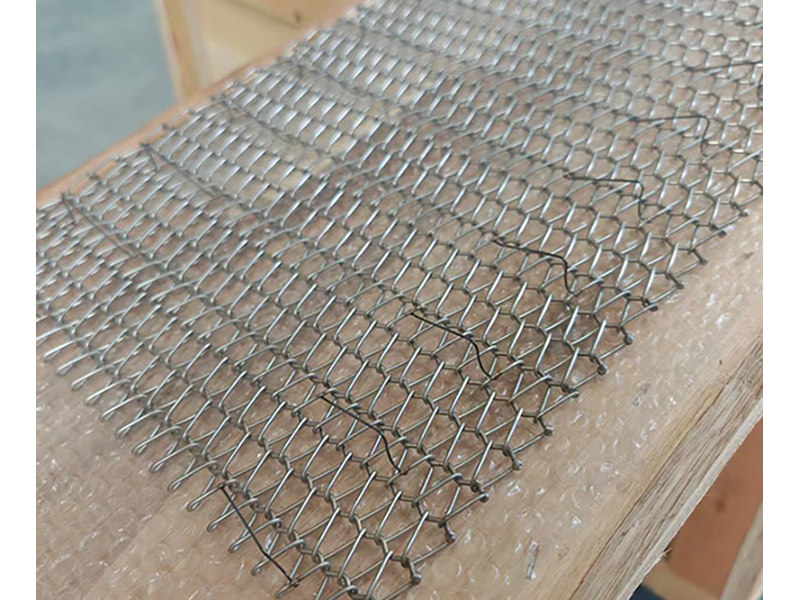

HO CHI MINH CITY, VIETNAM – June 3, 2025 – Huada Mesh belt, a pioneer in high-temperature wire mesh belt solutions, has delivered a custom-engineered 310S stainless steel Furnace Conveyor belt to a leading Vietnamese industrial equipment manufacturer. The mesh belt, featuring 3.0mm wire diameter and optimized open-mesh design, will operate in a 1,100°C continuous heat treatment furnace for automotive component processing.

Technical Specifications & Application

• Material: 310S austenitic stainless steel (Cr25Ni20)

• Operating Temperature: Sustained 1,100°C with peak tolerance to 1,200°C

• Wire Diameter: 3.0mm precision-welded construction

• Application: Automotive gear carburizing furnace with 24/7 operation

The belt's low thermal expansion coefficient(±0.5mm dimensional stability) and carburization resistance address critical challenges in Vietnam’s expanding heat treatment sector, where temperature fluctuations often cause conventional belts to warp or crack.

Engineering Advantages

Leveraging 30+ years of metallurgical expertise, GlobalMeshBelt engineered the solution with:

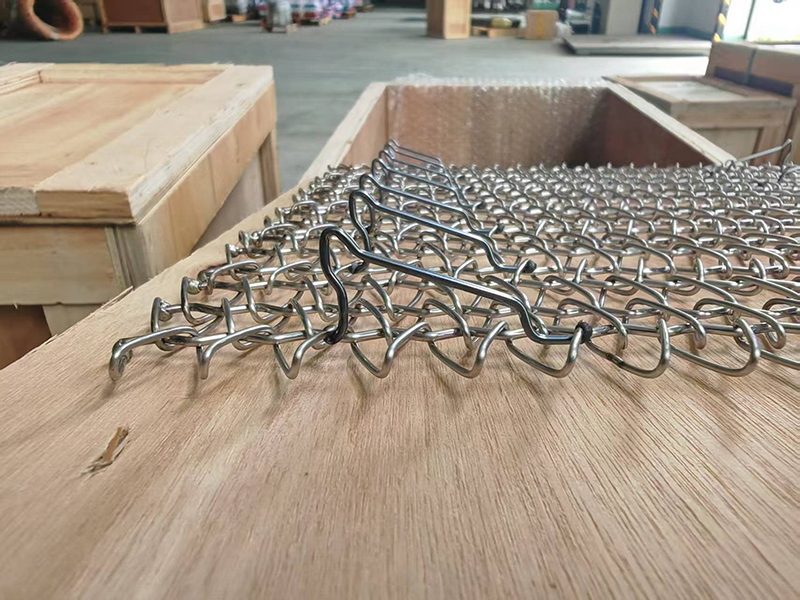

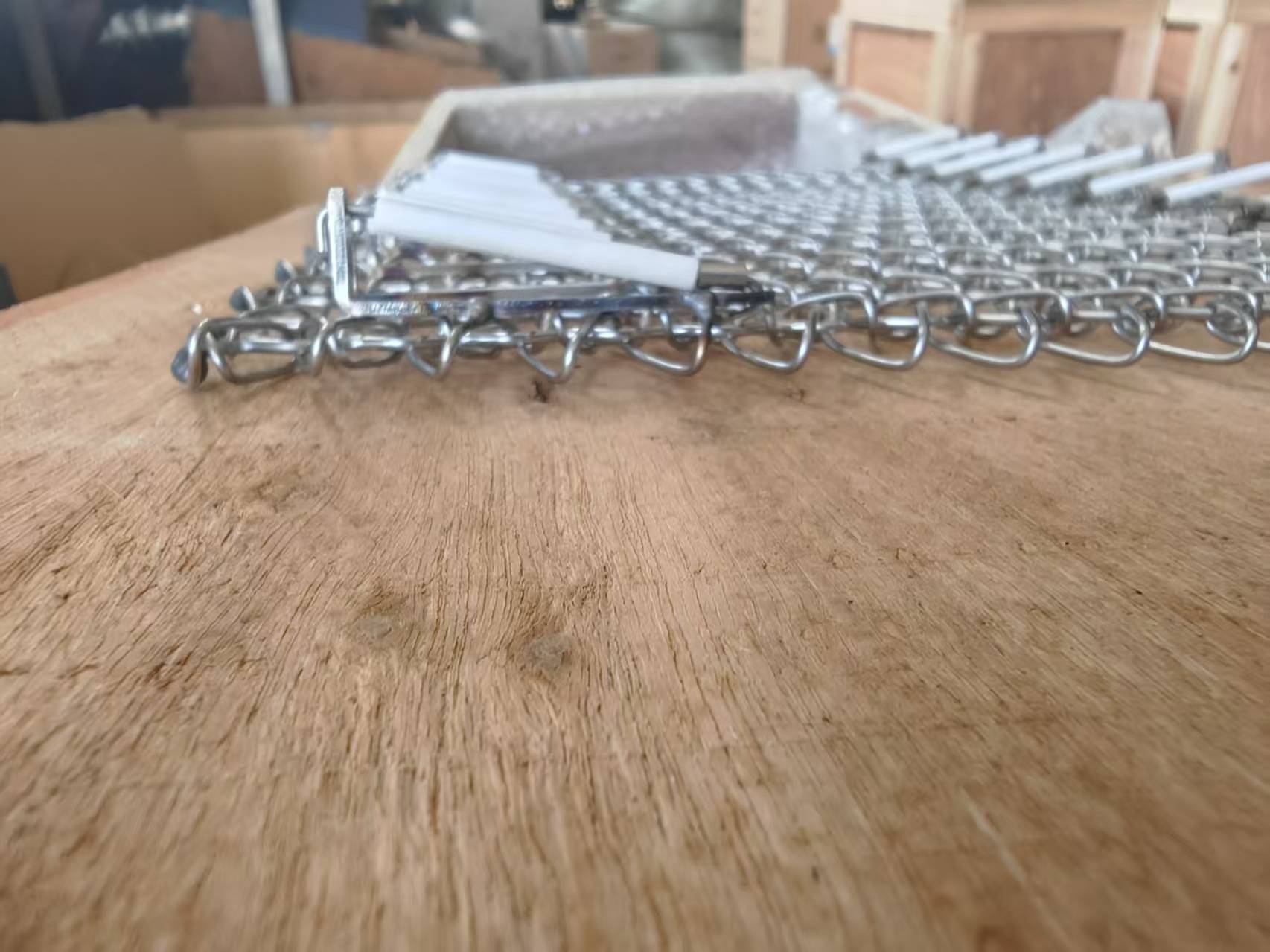

• Spiral-lock joints preventing edge unraveling under thermal stress

• Large open mesh (15mm pitch) enabling uniform heat distribution

• CIP-ready surface for acid cleaning compatibility

"Our Vietnam client required a mesh belt surviving >5,000 thermal cycles," noted our Technical Director. "310S alloy’s nickel-chromium matrix provides superior oxidation resistance versus standard 304/316 grades in extreme furnace environments."

Market Context

Vietnam's manufacturing growth drives demand for premium thermal processing belts, with heat treatment equipment imports rising 18% (Vietnam Customs, 2024). This installation aligns with regional shifts toward nergy-efficient sintering and precision metallurgy.

About Huada Mesh Belt

With ISO 9001-certified production in China, Huada Mesh Belt specializes in furnace conveyor belts & furmace Mesh Belts for:

• Powder metallurgy sintering

• Glass tempering lehrs

• Continuous carburizing lines

• Ceramic kiln transfers

Explore our high-temperature solutions: www. site_5692daef-da17-420f-94c5-497c98eb8172