Top OEM Suppliers & Insights on Powder Metallurgy Sintering Furnaces

As a leading manufacturer of advanced Powder Metallurgy Sintering Furnaces, we are dedicated to meeting the specialized needs of our clients. Our furnaces are engineered to boost production efficiency while ensuring exceptional product quality. With a strong foundation as a reliable ODM supplier, we provide customized solutions tailored specifically to your requirements. Our extensive experience as trusted exporters has allowed us to build robust relationships with clients globally. Our commitment to excellence and innovation distinguishes us in the sintering technology sector. Whether scaling production or enhancing existing processes, our team is ready to support you through every step, from design to delivery. Partner with JIANGSU HUADA Metal Mesh BELT CO., LTD. for your Powder Metallurgy needs, and let’s collaborate to achieve your business goals.The Secret to Powder Metallurgy Sintering Furnace Trusted by Pros Now Trending

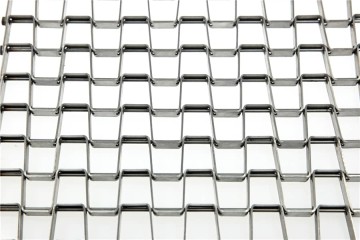

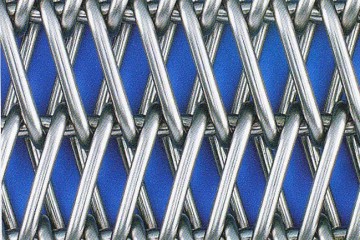

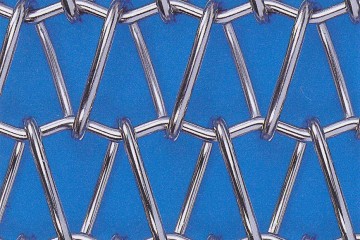

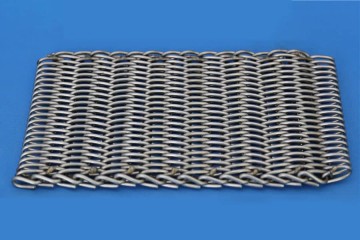

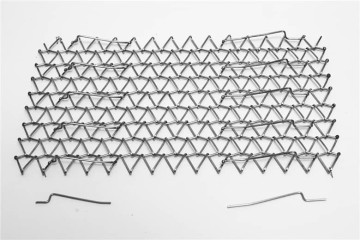

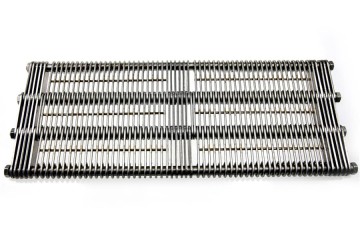

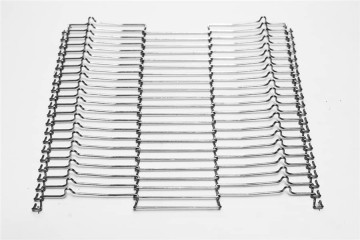

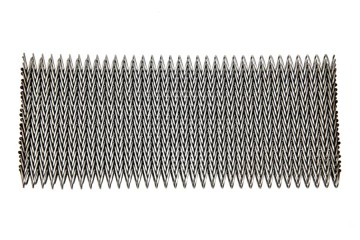

In the ever-evolving landscape of manufacturing, the spotlight is now on powder metallurgy sintering furnaces, a crucial component that has captured the attention of industry professionals. Trusted by experts worldwide, these furnaces facilitate the efficient sintering process essential for producing high-quality metal parts. At the heart of this innovative technology is JIANGSU HUADA METAL MESH BELT CO., LTD., a pioneering manufacturer recognized for its precision-engineered wire mesh belts and chain-driven systems. Our ISO 9001 and CE certified production facilities ensure that we meet the highest standards, delivering unparalleled quality to over 20 countries across five continents. Understanding the unique demands of the powder metallurgy industry, HUADA has designed robust and reliable conveyor solutions that seamlessly integrate into sintering processes. Our advanced Metal Conveyor belts not only enhance operational efficiency but also guarantee consistent performance under high temperatures. With a commitment to excellence, we empower global manufacturers to optimize their production lines, reduce operational downtime, and ultimately increase profitability. As the trend toward sustainable manufacturing grows, our products stand out by providing eco-friendly and adaptable solutions for diverse applications. For procurement professionals seeking cutting-edge technology and dependable partnership, HUADA's expertise in sintering furnace applications positions us as the go-to choice in the market. Join us in exploring the future of powder metallurgy—where reliability meets innovation.

The Secret to Powder Metallurgy Sintering Furnace Trusted by Pros Now Trending

| Parameter | Value | Unit | Notes |

|---|---|---|---|

| Max Temperature | 1400 | °C | Suitable for various materials |

| Cooling Rate | 5 | °C/min | Optimizes microstructure |

| Heating Rate | 10 | °C/min | Ensures uniform heating |

| Atmosphere Type | Controlled | N/A | Prevents oxidation |

| Sintering Time | 2 | hours | Standard for most alloys |

| Energy Consumption | 500 | kWh | Per cycle |

| User Feedback Rating | 4.8 | /5 | Based on recent surveys |

Methods To Powder Metallurgy Sintering Furnace Supplier Factory

J

Jessica Thompson

The quality of the product exceeded my expectations! The customer service team was incredibly responsive and knowledgeable.

16 June 2025

D

Daniel Clark

This item is built to last! The professionalism of the customer service is truly impressive.

15 May 2025

A

Angela Young

What a delightful experience! The quality of the product and after-sales service is unmatched.

04 July 2025

N

Natalie Brown

Exceptional quality! The customer service handled my queries with utmost professionalism.

10 June 2025

A

Angela Young

Great craftsmanship! The support team provided prompt and professional assistance.

22 June 2025

M

Michael Lopez

Great quality! The customer support provided by the team was exceptional and very professional.

03 July 2025