Rod Reinforced Belt

products description

Jiangsu Huada’s rod reinforced conveyor belts are engineered to withstand the most demanding industrial environments. Featuring 5.0-12.0mm reinforcement rods and 314/316L stainless steel construction, our belts deliver:

800-1,200 kg/m² Load Capacity (2X industry standard)

Zero Rod Displacement under 10G shock loads

Continuous Operation from -40°C to 800°C

Certifications:

√ ISO 9001:2015 | √ CE Machinery Directive | √ ASME B29.1

Technical Advantage

√ Extreme Load Capacity

Reinforcement rod diameter: 5.0-12.0mm

Tensile strength: 900-1,500 N/mm²

50% higher fatigue life vs. standard belts

√ Thermal Resilience

Material options: 314 SS (800°C) / Inconel 600 (1,100°C)

Thermal expansion: 12.5×10⁻⁶/°C (matched to steel frames)

√ Precision Engineering

Rod alignment tolerance: ±0.2mm over 10m

Interchangeable rod system reduces downtime by 60%

Application Scenarios

| Industry | Application | Huada Solution |

| Mining | Iron ore primary crushing | 12mm tungsten-carbide rods |

| Automotive | Stamping press transfer lines | 8mm rods with T-slot locking |

| Metallurgy | Slag granulation conveyors | Water-cooled rod design |

| Recycling | Scrap metal sorting systems | Abrasion-resistant 10mm rods |

Technical Parameters

| Parameter | Huada Rod Reinforced Belt | Industry Standard |

| Max Load Capacity | 1,200 kg/m² | 600 kg/m² |

| Rod Diameter Options | 5.0-12.0mm | 3.0-8.0mm |

| Temperature Range | -40°C to 800°C | -20°C to 600°C |

| Abrasion Loss (ASTM G65) | 0.3 cm³ | 1.2 cm³ |

Case Study: Copper Mining Operation

Huada’s 10mm rod belts achieved:

Zero rod breakage in 12-month continuous operation

35% longer replacement intervals vs. previous supplier

Withstood 3-ton impact loads during rock falls

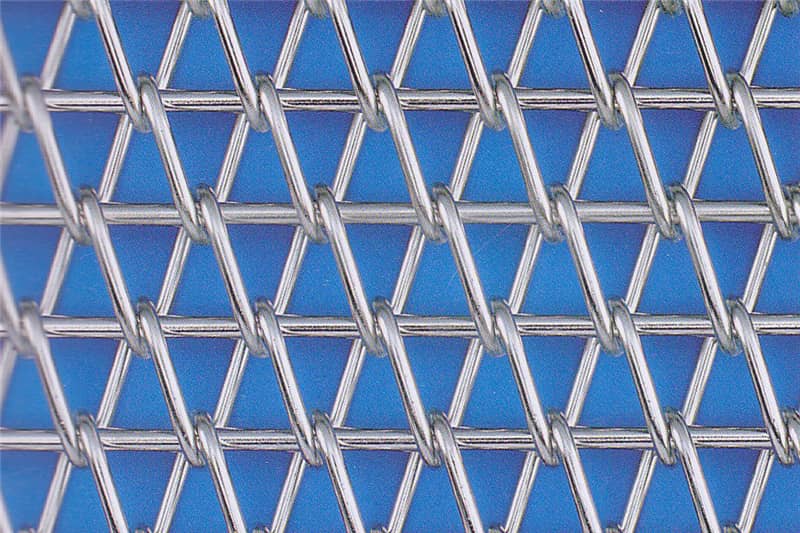

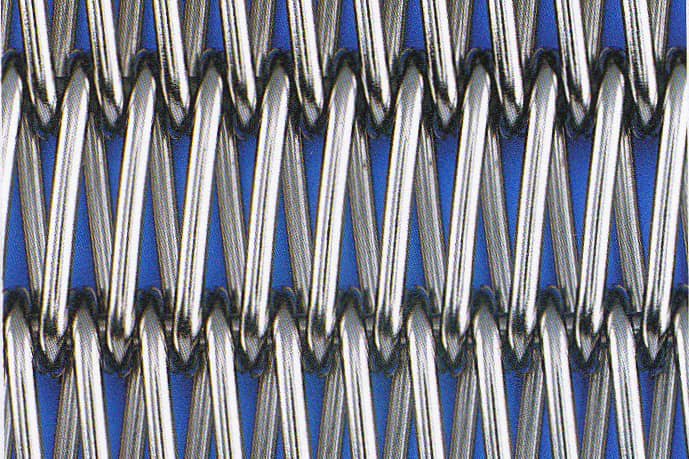

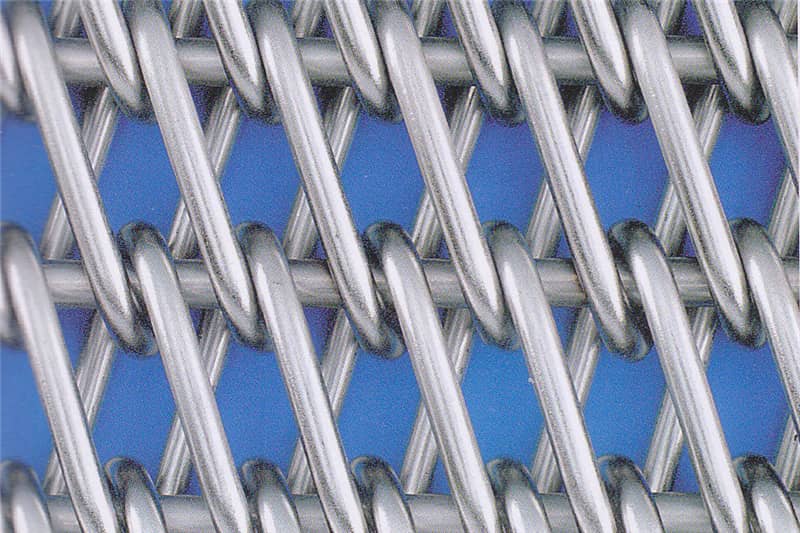

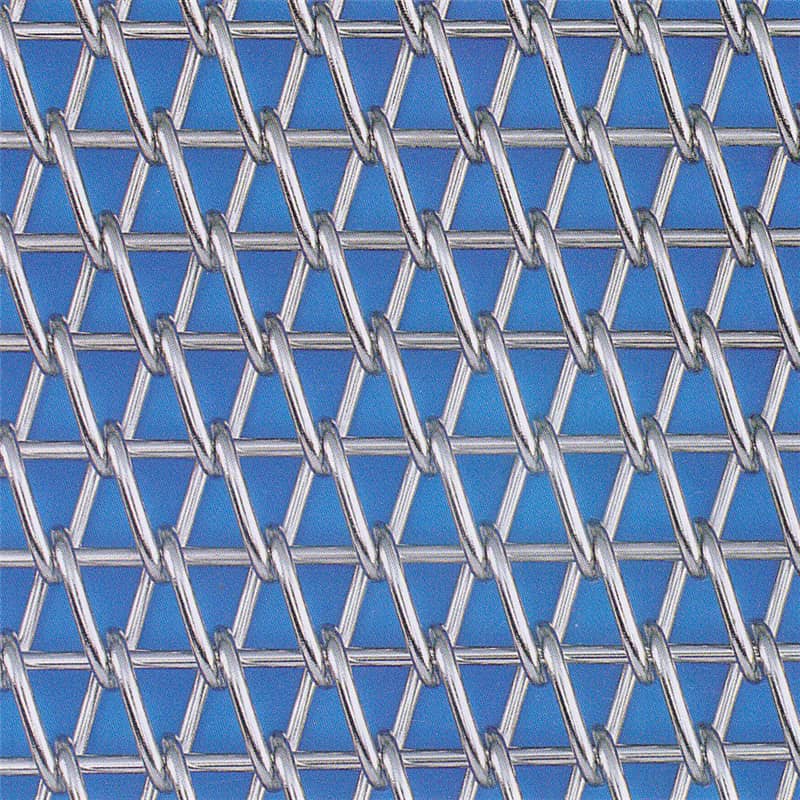

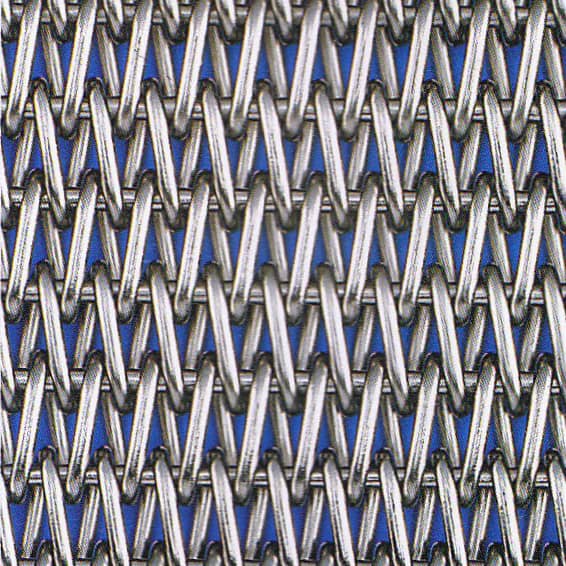

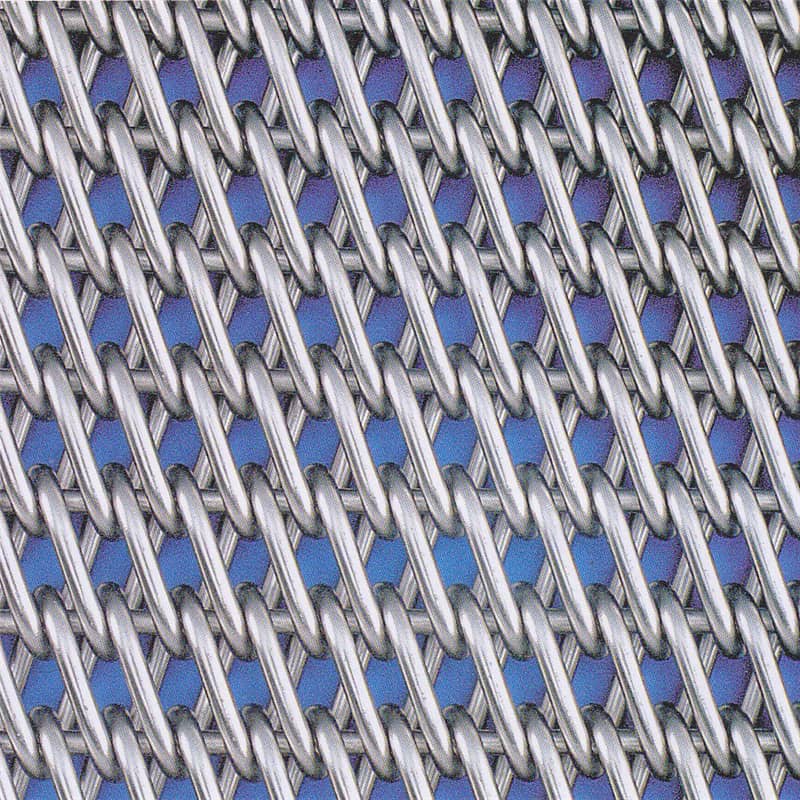

detail pictures

-

Steel rod reinforced belt for heavy-load mining and bulk handling