CE Certified Sintering Furnace Mesh Belt Manufacturers & Exporters for Quality Solutions

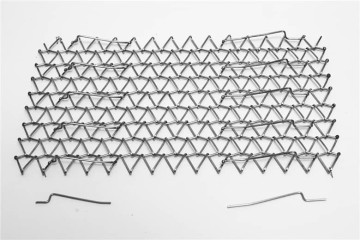

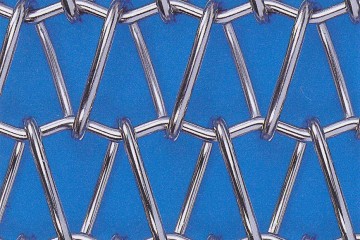

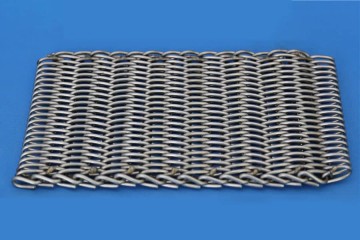

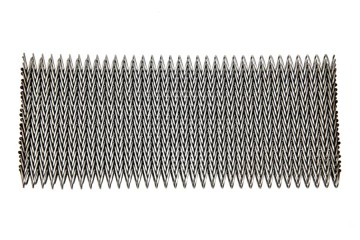

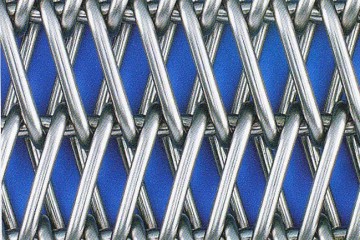

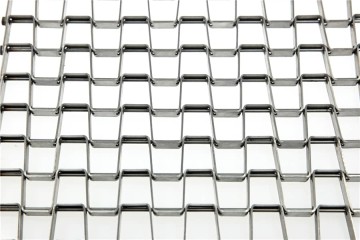

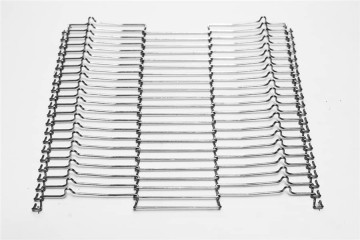

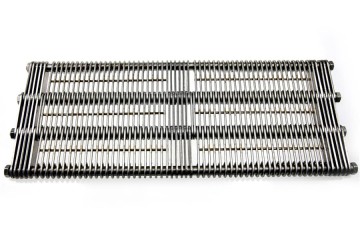

As a manufacturer committed to excellence, we proudly present our Sintering Furnace Mesh Belt, engineered for peak performance in high-temperature environments. Our belts are distinguished by exceptional durability and efficiency, making them ideal for a diverse range of industries. At JIANGSU HUADA METAL MESH BELT CO., LTD., we understand the unique demands of our clients and have tailored our products to meet those needs. Crafted from advanced materials, our sintering furnace mesh belts are designed to endure extreme conditions while preserving structural integrity. Whether you are a large corporation or a small business, we offer customized solutions to enhance your production processes. Partnering with us ensures access to reliable, high-quality products that elevate your operations.Why Consider Sintering Furnace Mesh Belt Your End-to-End Solution Stands Out

In an ever-evolving industrial landscape, finding the right solutions for your manufacturing needs is paramount. As a leading manufacturer, JIANGSU HUADA METAL MESH BELT CO., LTD. stands out with our high-performance sintering furnace mesh belts designed for efficiency and durability. Our precision-engineered Wire Mesh belts and chain-driven systems have been rigorously developed to meet the highest standards, ensuring optimal performance in sintering applications. With ISO 9001 and CE certifications, clients can trust our commitment to quality and reliability. Choosing our sintering furnace mesh belt as your end-to-end solution not only enhances operational efficiency but also extends the lifespan of your equipment. Our belts are crafted to withstand high temperatures and corrosive environments, making them ideal for various applications in sectors ranging from metallurgy to ceramics. By integrating our mesh belts into your production line, you are investing in a future-proof solution that supports your manufacturing goals while adhering to international safety and quality standards. With our extensive experience serving more than 20 countries across five continents, HUADA is dedicated to providing tailored solutions that meet your specific requirements. Partnering with us means gaining access to innovative technologies and exceptional customer service that can help optimize your operations. Explore the advantages of our sintering furnace mesh belts and discover how we can elevate your production capabilities while driving global competitiveness.

Why Consider Sintering Furnace Mesh Belt Your End-to-End Solution Stands Out

| Feature | Benefits | Applications | Material Used |

|---|---|---|---|

| High Thermal Efficiency | Reduced energy costs and improved processing times | Metal fatigue treatment, ceramics | Stainless Steel |

| Custom Design Options | Tailored solutions for specific production needs | Automotive components, electronics | Nickel Alloy |

| Durability | Long lifespan with minimal maintenance | Aerospace parts, industrial tooling | Inconel |

| High Load Capacity | Supports heavy loads without deformation | Heavy machinery, construction equipment | Carbon Steel |

| Versatile Temperature Range | Suitable for a wide array of sintering processes | Powder metallurgy, glass-making | Ceramic Coated Steel |

Why Professionals Prefer Sintering Furnace Mesh Belt Exceeds Industry Benchmarks Is The Best

S

Sarah Martin

I am thrilled with my purchase! The quality is excellent, and the service team was outstanding.

09 May 2025

D

David Hall

What a gem! The product is high quality, and the after-sales service team is fantastic.

11 May 2025

B

Barbara Miller

This item is of excellent quality! The service personnel were knowledgeable and amicable.

06 July 2025

V

Victoria Wilson

Incredible quality! The support staff was professional and prompt in resolving my issues.

21 June 2025

S

Sophia Lee

Amazing product! The attention from the support staff was commendable and very professional.

27 June 2025

M

Michael Clark

Very satisfied with my purchase! The quality and service level are remarkable.

20 May 2025