Solar Thermal Oven Belts for Module Assembly

products description

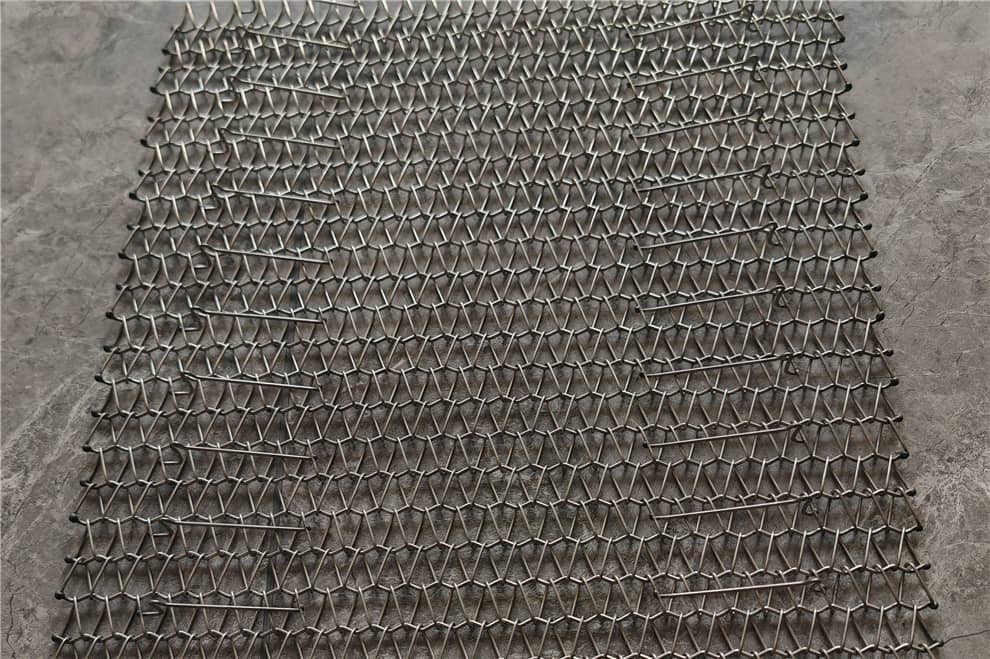

Our solar drying oven mesh belts use 316L stainless steel with anti-static coating, designed for PV backsheet E-coating and pre-lamination drying. Chemical-resistant structure withstands acid washdown.

Jiangsu Huada’s PV cell drying oven belts are engineered for critical moisture removal in monocrystalline/polycrystalline silicon production. Our 316L stainless steel conveyor systems deliver:

< 5ppm residual moisture (verified by FTIR analysis)

30% faster drying cycles vs. conventional mesh belts

Zero metal contamination (ICP-MS tested to <0.1ppb)

Key Applications:

→ Post-texturing cleaning drying

→ PSG removal rinse drying

→ Edge isolation process drying

Technical Advantages (Bullet Points)

√ Superior Chemical Resistance

Withstands 1-10% HF / HNO3 residuals

Passes 1,000-hour salt spray test (ASTM B117)

√ Optimized Drying Performance

85% open area design for laminar airflow

Mirror-polished surface (Ra ≤0.4μm) minimizes water adhesion

√ Thin Wafer Protection

ESD-safe (surface resistance 10⁶-10⁹Ω)

Rounded edge guides reduce breakage to <0.05%

Performance Comparison Table

| Parameter | Huada Drying Belt | Industry Standard |

| Acid Resistance | Up to 10% HF | ≤5% HF |

| Drying Uniformity | ±1.5% RH | ±5% RH |

| Breakage Rate (160μm) | 0.03% | 0.15-0.3% |

| Energy Consumption | 8.2 kW·h/m² | 12.5 kW·h/m² |

Application Spotlight

Challenge: Inconsistent drying on textured wafers causes efficiency loss.

Solution:

Material: 316L electropolished stainless steel

Structure: standoff design reduces contact area

Validation:

• 22% faster drying (180s → 140s)

• Metal contamination <0.1ppb (ICP-MS)

Customer Case Study

TOPCon Cell Manufacturer Testimonial:

After switching to Huada’s drying belts, we achieved:

"0.03% breakage rate (previously 0.18%)

€75k/year LN2 cost savings

Zero corrosion after 3-year DH2000 testing"

detail pictures