Spiral Conveyor Belt

products description

Stainless steel spiral conveyor belts operate at -40°C for spiral freezers, HACCP/FDA compliant. Sanitary design with quick-release hinges for meat, seafood & frozen food processing.

Jiangsu Huada’s spiral conveyor belts are engineered for ultra-low temperature efficiency in spiral freezers, delivering -40°C to 50°C operational stability and zero product sticking for:

Individual Quick Freezing (IQF) of shrimp, berries, and vegetables

Prepared meal flash-freezing

High-volume meat processing

Certifications:

√ ISO 9001:2015 | √ FDA 21 CFR 177.2600 | √ EHEDG EL Class

Technical Advantage

√ Cryogenic Performance

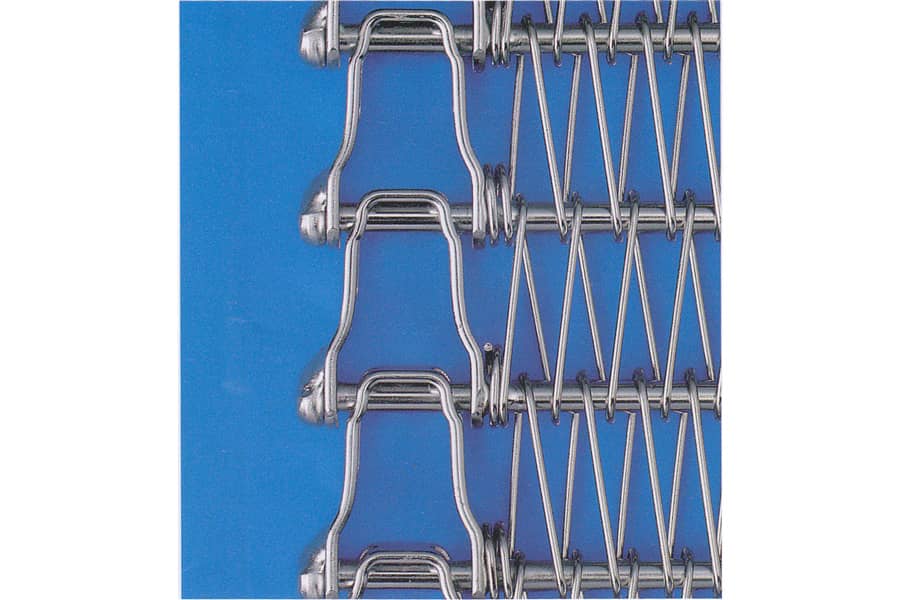

Material: 316L stainless steel with electropolished finish (Ra ≤0.6μm)

Operational range: -40°C to 50°C (5000+ thermal cycles tested)

√ Food Safety Assurance

Non-toxic PTFE-free coating

Open area ratio: 45-85% (customizable airflow optimization)

√ Operational Efficiency

30% faster freezing vs. traditional belts

Quick-release tensioners reduce cleaning time by 50%

Application Scenarios

| Application | Product Example | Huada Solution |

| Seafood IQF | Shrimp, Scallops | 60% open area + marine-grade SS |

| Vegetable Freezing | Peas, Carrot Cubes | Micro-bump surface anti-stick design |

| Ready Meals | Frozen Pizzas, Dumplings | 800mm belt width for tray systems |

| Meat Processing | Chicken Nuggets | Heavy-duty 4.0mm wire construction |

Technical Parameters

| Parameter | Huada Spiral Belt | Industry Standard |

| Temperature Range | -40°C to 50°C | -30°C to 40°C |

| Belt Speed | 0.1-1.5 m/min | 0.1-1.0 m/min |

| Cleaning Cycle Time | 25 minutes (CIP ready) | 45+ minutes |

| Energy Consumption | 0.8 kW/m² | 1.2 kW/m² |

Case Study: Global Seafood Processor

Huada’s spiral belts achieved:

27% higher throughput with 1.2m/min belt speed

Zero product loss from sticking in 12-month operation

Passed BRCGS AA+ audit with EHEDG-certified design

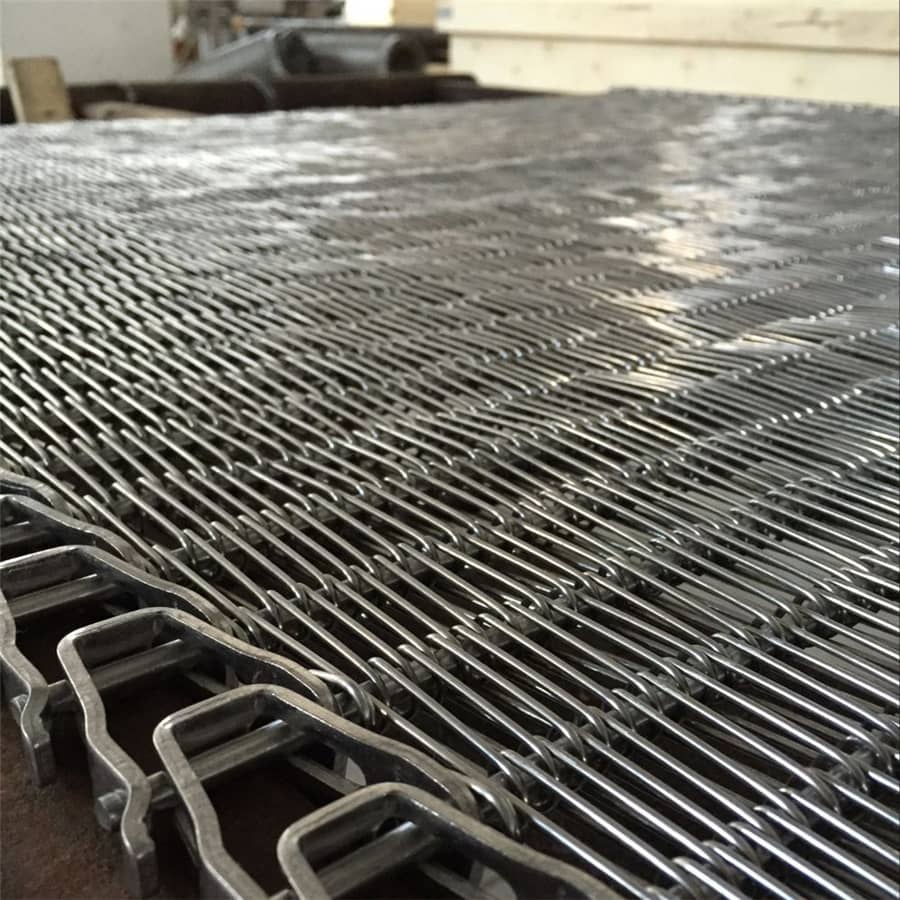

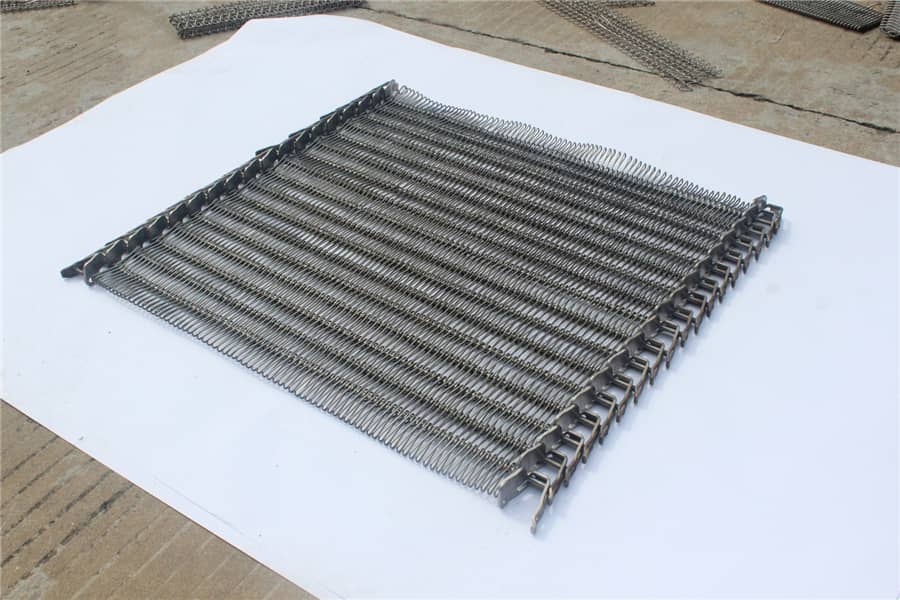

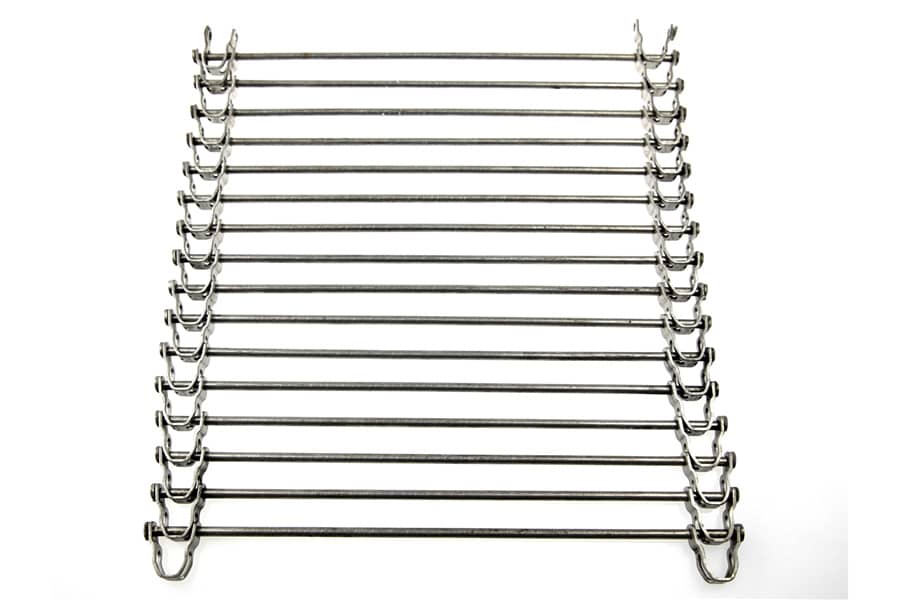

detail pictures