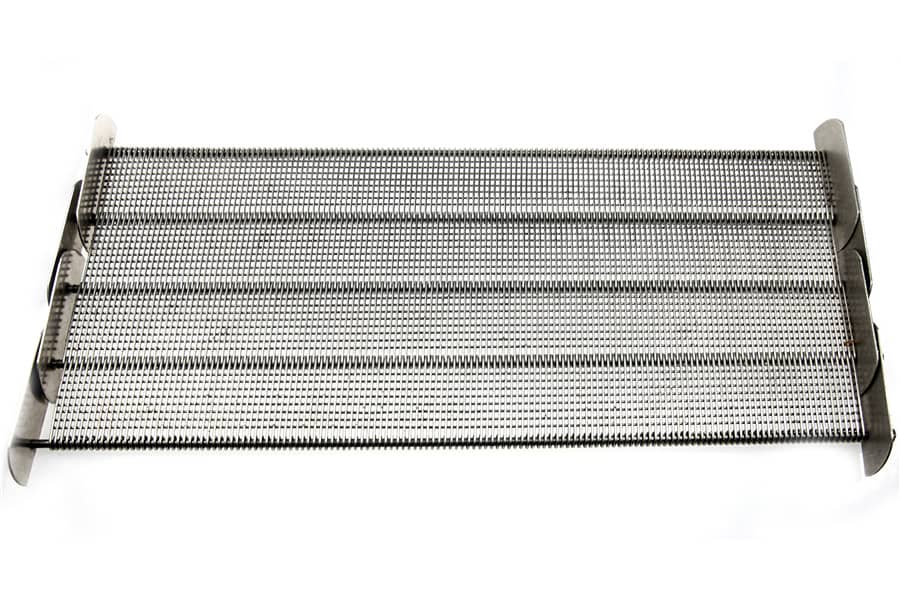

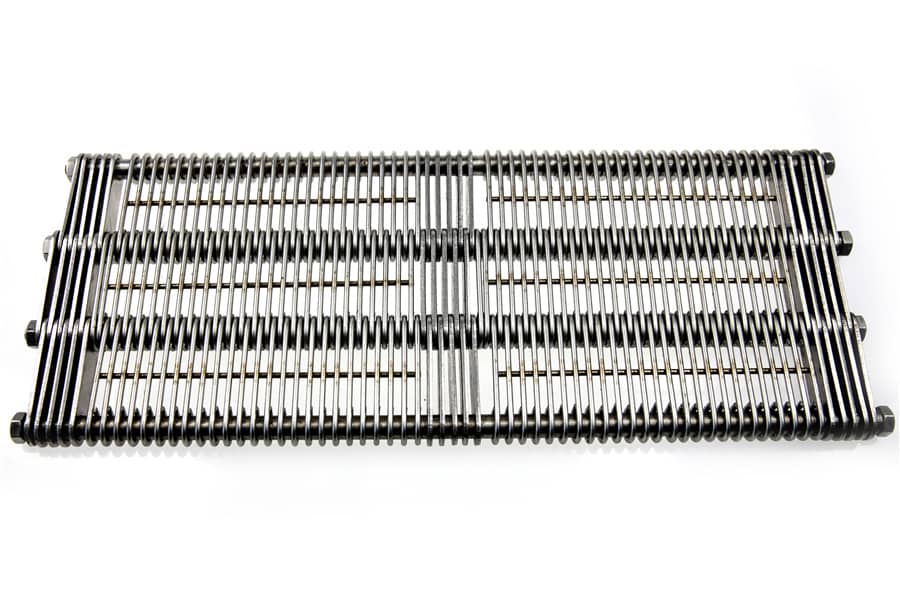

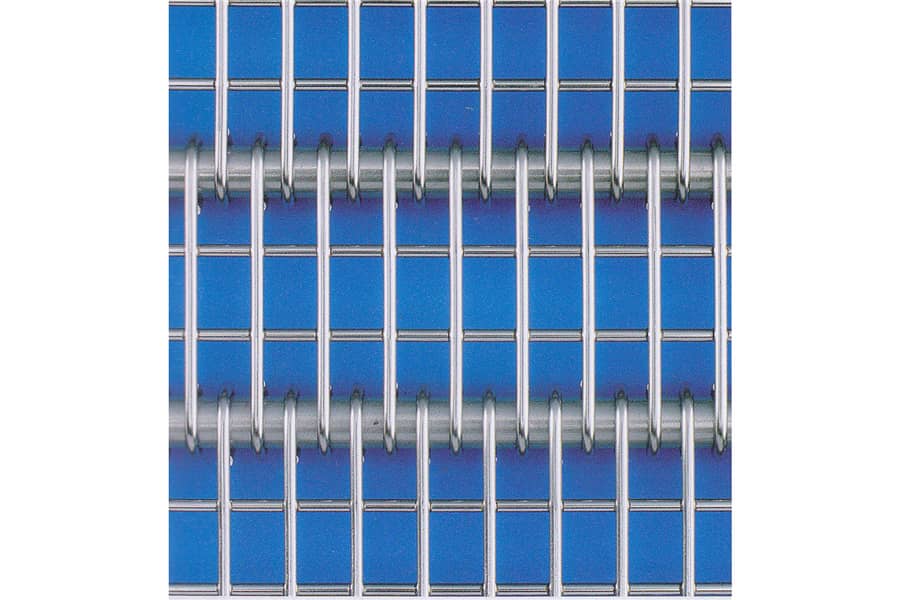

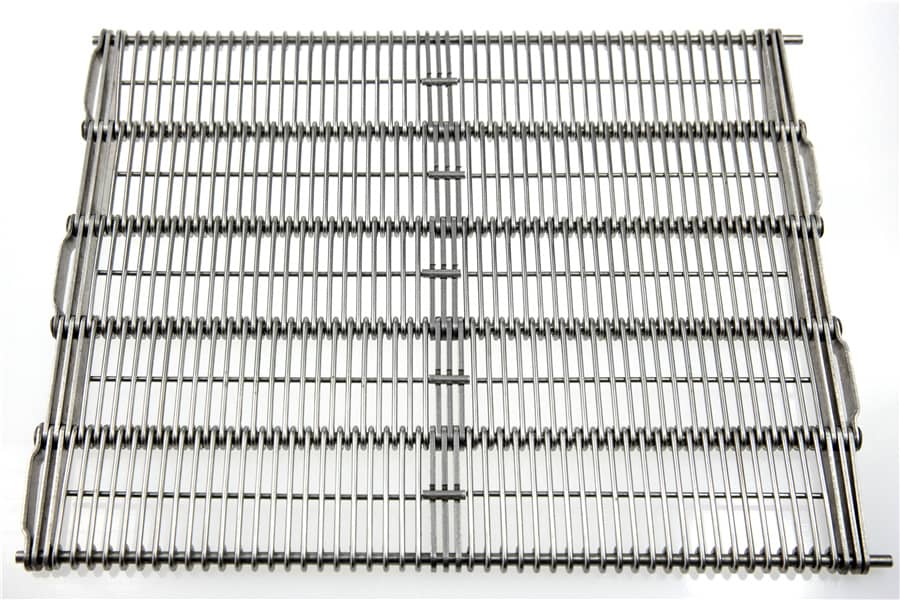

Wire Ring Belt

products description

Wire Ring Belt (Eye-Link/Flex) with 316 SS construction and CIP-ready design, engineered for beer pasteurization systems. Customizable configurations ensure corrosion resistance and food-grade durability.

Jiangsu Huada’s wire ring belts are precision-engineered for beverage bottle washing, can cleaning, and liquid filling operations. Made from 304/316L stainless steel with laser-welded joints, our belts deliver:

Zero Bacterial Harborage (EHEDG EL Class I design)

Withstands 100 bar CIP Cleaning

50% Longer Lifespan vs. traditional carbon steel belts

Certifications:

√ FDA 21 CFR 177.2600 | √ EHEDG EL Class I | √ ISO 9001:2015

Technical Advantage

√ Beverage Industry Optimized

Material: 304/316L SS (pH 1-14 resistance)

Open area: 50-75% for optimal drainage & drying

√ High-Pressure Resilience

Laser-welded joints withstand 100 bar spray

Passes 200,000 CIP cycles (EN 1672-2:2020)

√ Operational Efficiency

Noise level: <68 dB(A) at 2m/s

Quick-release tensioners reduce downtime by 40%

Application Scenarios

| Application | Industry Example | Huada Solution |

| Bottle Washing | Beer, Soda, Water | 316L SS with EHEDG-certified design |

| Can Rinsing | Energy Drinks, Juices | 50mm ring diameter for can stability |

| Filling Lines | Dairy & Beverages | 304 SS with FDA-compliant finish |

| Packaging | PET Bottle Handling | Low-friction surface for smooth transfer |

Technical Parameters

| Parameter | Huada Wire Ring Belt | Industry Standard |

| Max CIP Pressure | 100 bar | 60 bar |

| Corrosion Rate (316L) | <0.01 mm/year | 0.05 mm/year |

| Drainage Efficiency | 95% water removal in 15s | 80% in 30s |

| Hygiene Certification | EHEDG EL Class I | Basic CIP compliance |

Case Study: Global Brewery Group

Huada’s 316L wire ring belts achieved:

Zero biofilm formation in 12-month operation

30% faster line speeds with optimized drainage

Passed AIB International GMP Audit with perfect score

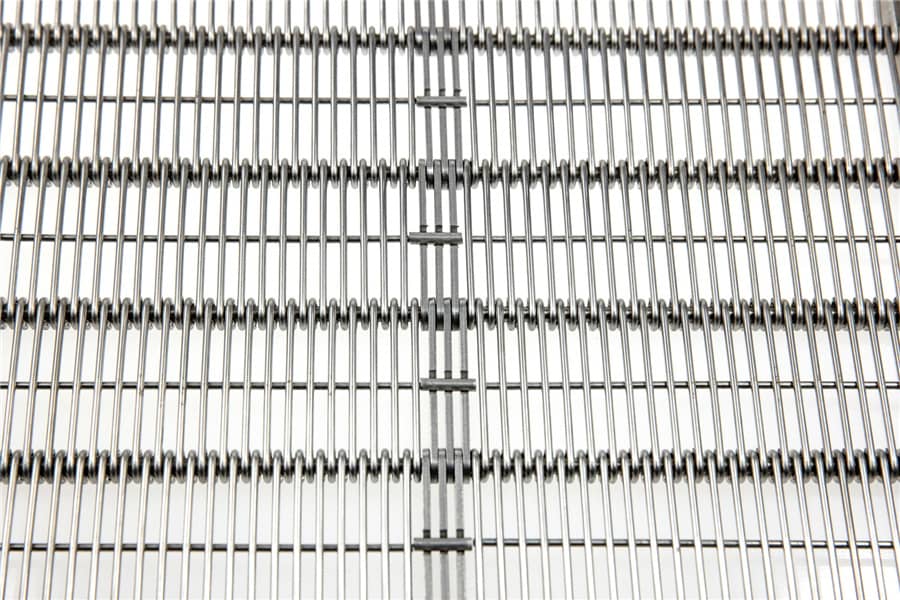

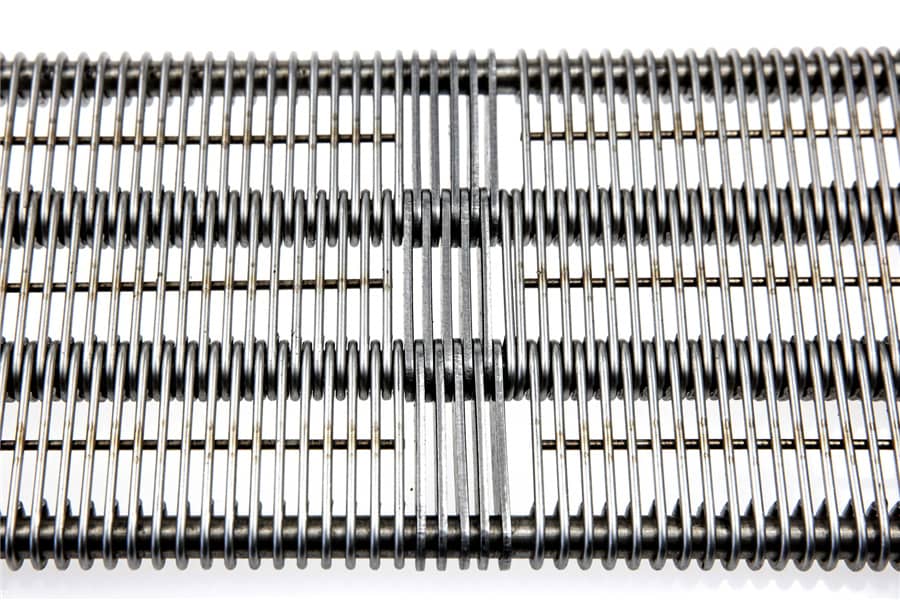

detail pictures